A high-efficiency molding process for cotton fabric

A molding process and fabric technology, which is applied in the processing of textile materials, fabric surface trimming, and processing of textile material carriers, etc., can solve limitations and other problems, and achieve the effects of strong elasticity, high work efficiency, and improved grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

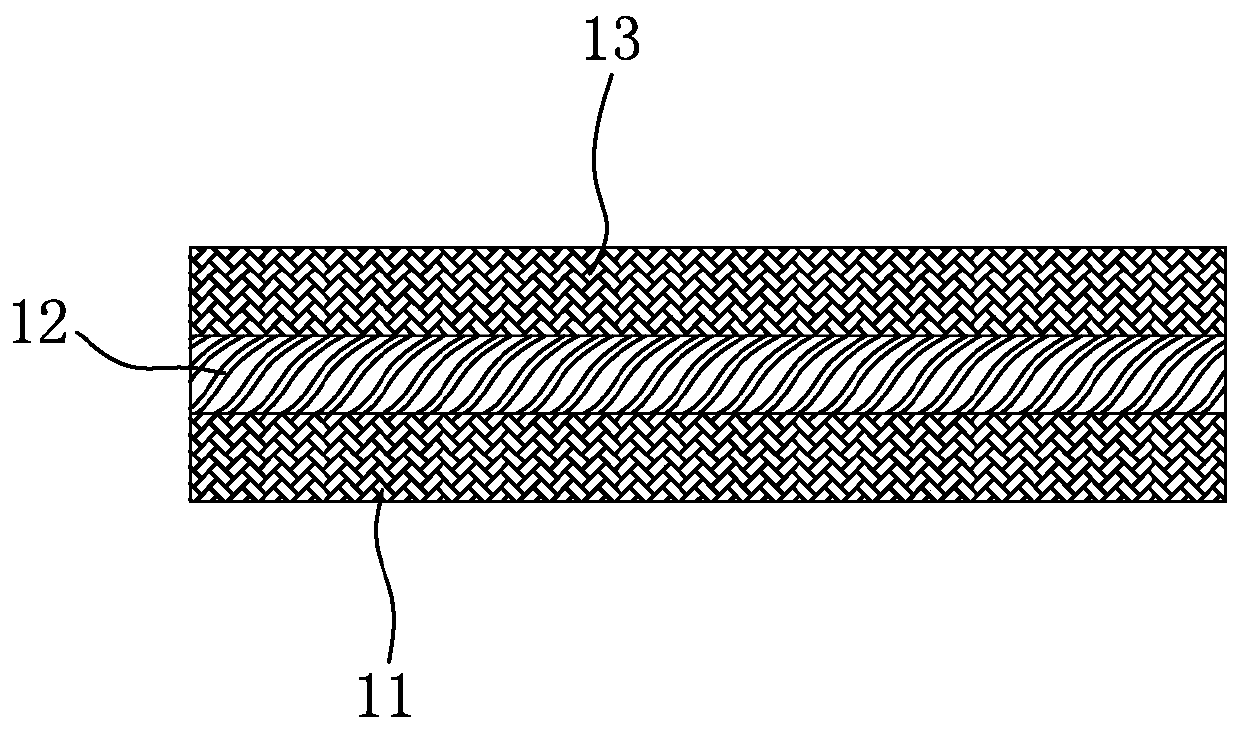

[0040] The invention relates to a molding process of high-elastic cotton fabric, which comprises the steps of forming an upper cotton fabric 13, forming a lower cotton fabric 11, forming spiral fibers 12, and forming the lower cotton fabric 11, spiral fibers 12 And the steps of sewing the upper cotton fabric 13 together.

[0041] Wherein, the upper layer of cotton fabric 13 and the lower layer of cotton fabric 11 are made by weaving, singeing, scouring, bleaching, pre-setting, sanding and softening and shaping, and the spiral fiber 12 is made of fiber monofilament. The spiral manufacturing device is formed. When actually forming, the lower layer of cotton fabric 11 is placed first, and then the spiral fiber 12 is laid on the lower layer of cotton fabric 11, and then the lower layer of cotton fabric 11 and the upper layer of cotton fabric are placed. Fabrics 13 are joined together.

[0042] In this way, the present invention adopts two layers of cotton fabrics as the upper lay...

Embodiment 2

[0045] As a more specific definition, it is a further definition made on the basis of the first embodiment. The weaving step includes: pure cotton yarns are used as warp and weft yarns to interweave the structure to obtain a gray cloth, and then the gray cloth is finished. Form fluff.

[0046] In this way, the gray cloth can be of higher quality by forming fluff.

Embodiment 3

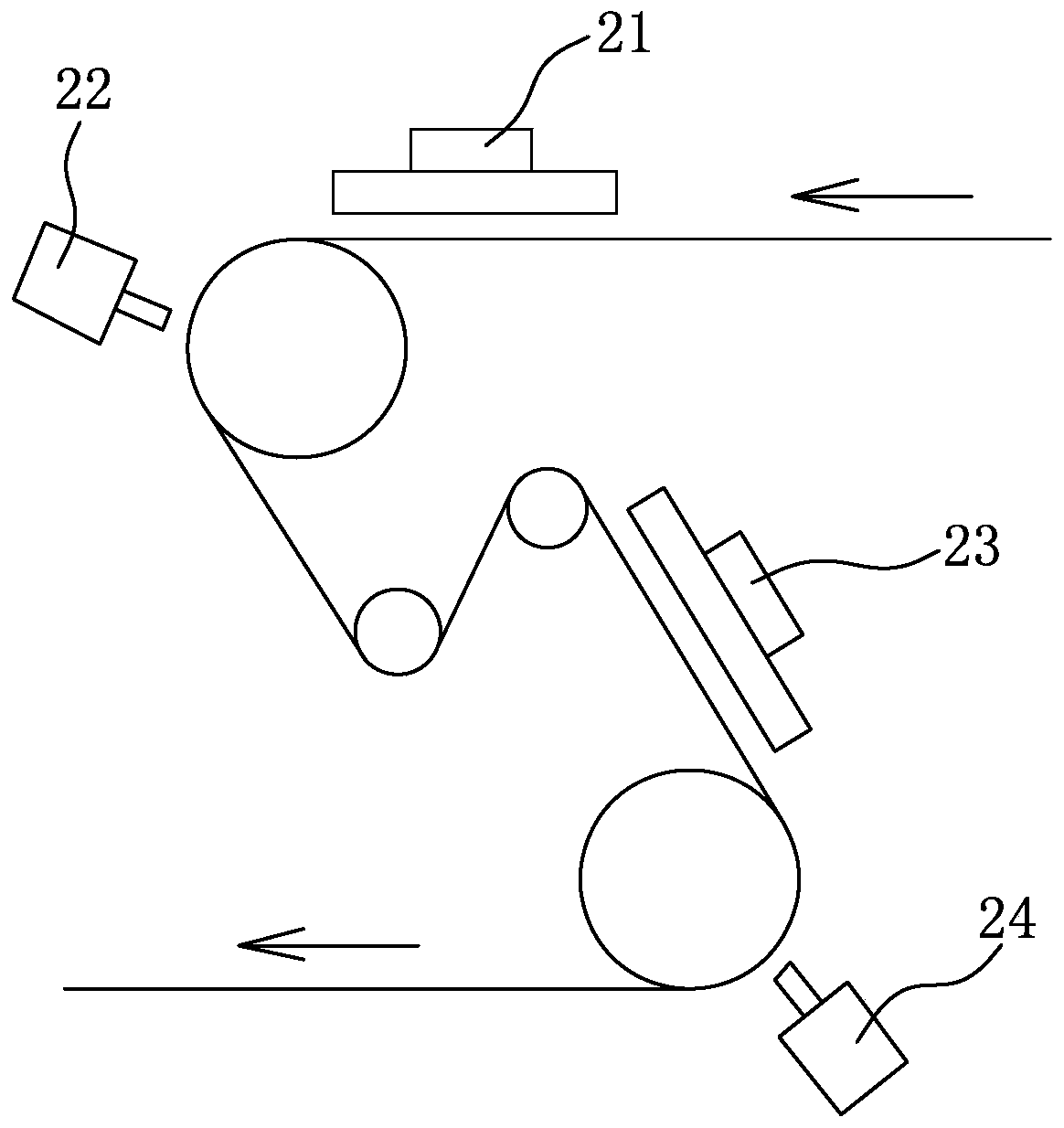

[0048] It is a further limitation made on the basis of Example 1 or Example 2, please refer to figure 2 As shown, the singeing step includes: applying static electricity to the first side of the gray cloth to make the fluff on the first side stand up, and then using the first flame injector 22 positioned on the first side to stand up the fluff on the first side. The fluff that got up is burnt; Then the second side of gray cloth is applied static electricity to allow the fluff of second side to stand up, and the second flame sprayer 24 that is positioned at second side is used again the fluff that stands up on second side burn it.

[0049]In this way, since the first flame injector 22 is arranged below the assembly line, especially after the static electricity is applied to the first side, the singeing operation is performed just after the static electricity is applied, which ensures the high efficiency of the singeing; An assembly line is arranged between an electrostatic ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com