A semi-trailer with a protective device

A protection device, semi-trailer technology, applied in the direction of freight vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of occupying space in the car, charging a long time, wasting time, etc., to prevent the sun and rain. The effect of showering and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

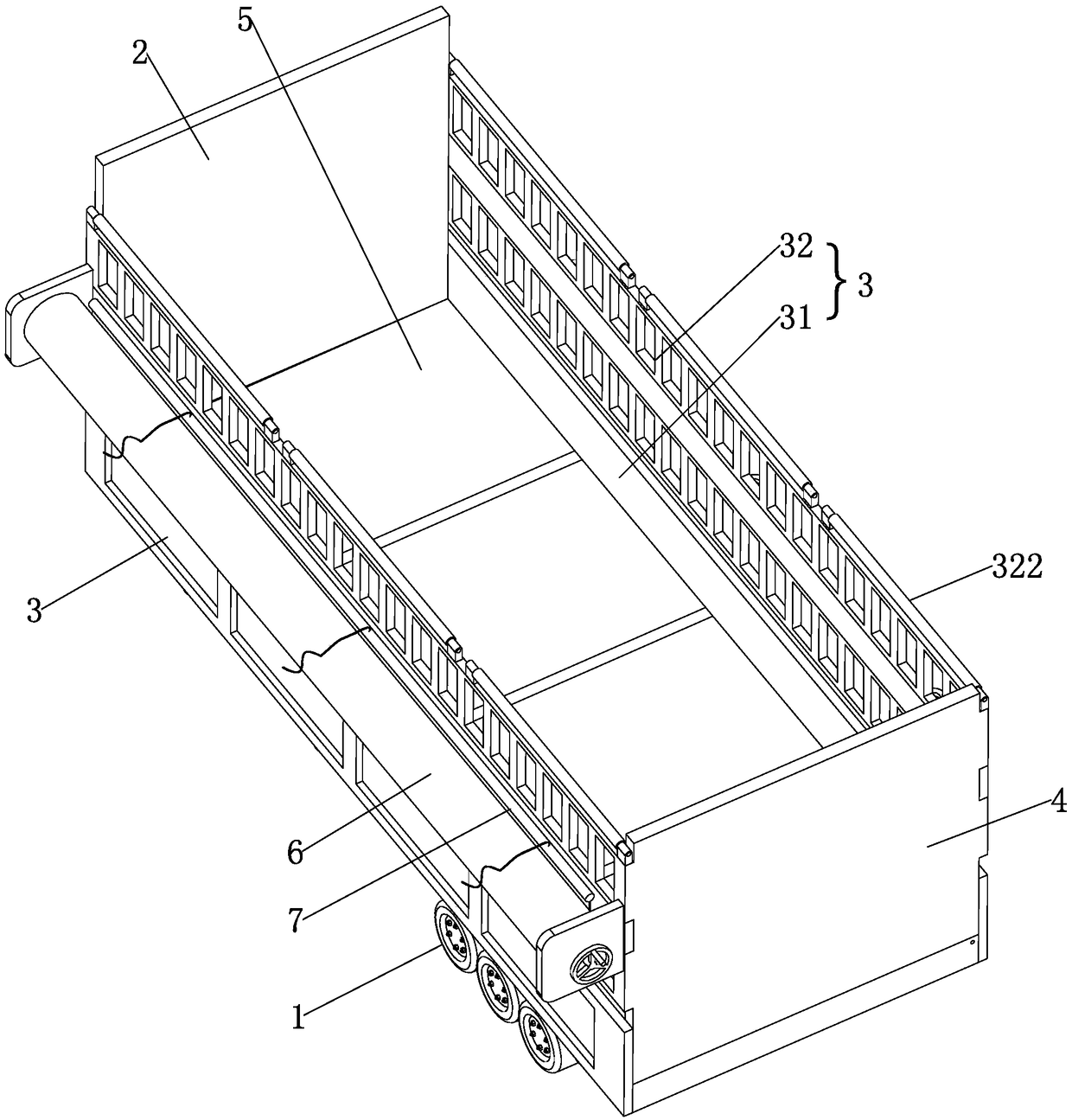

Embodiment 1

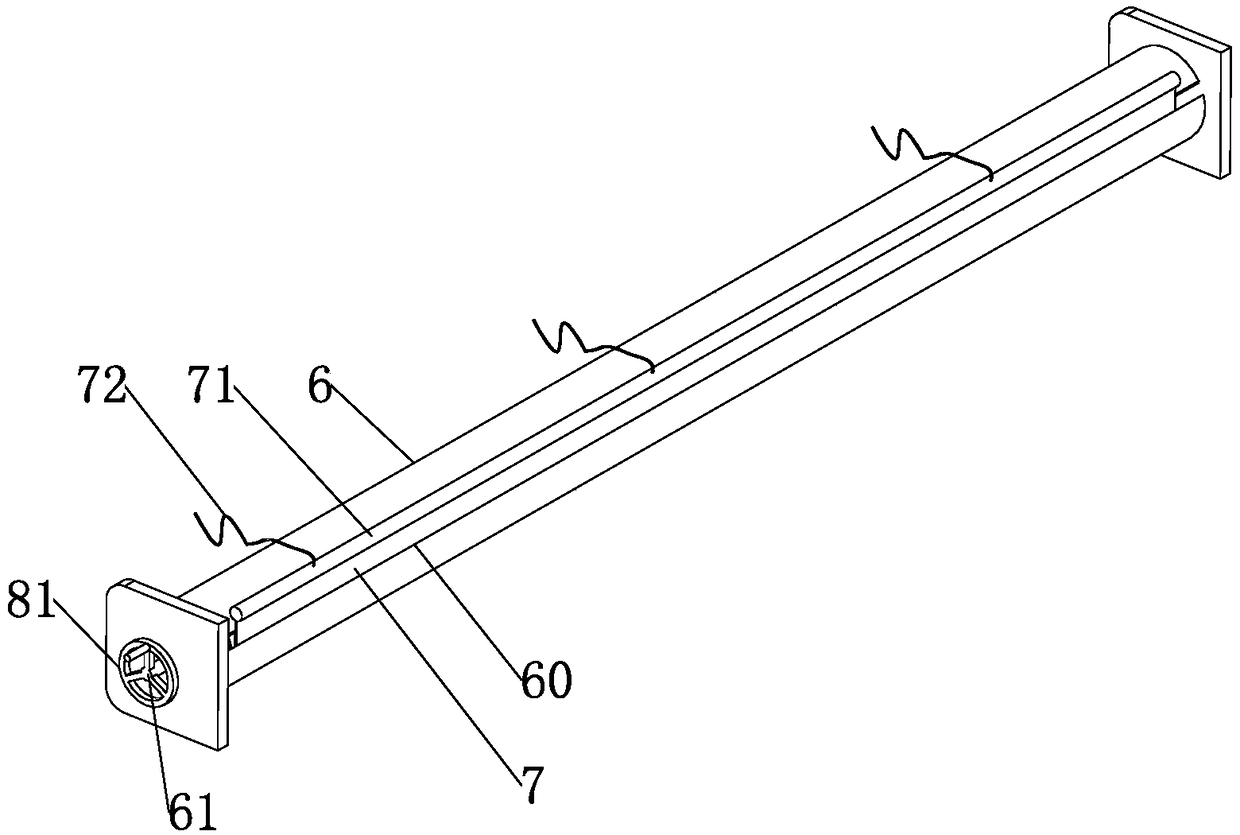

[0037] refer to figure 2 , the tarpaulin storage box 6 is a cylindrical barrel, and its upper side is provided with a tarpaulin inlet and outlet 60 near the car body. , and is as long as tarpaulin storage box 6. The inside of the tarpaulin storage box 6 is provided with a rotating shaft 61 , the rotating shaft 61 is arranged along the length direction of the tarpaulin storage box 6 , and the two ends are connected to the two ends of the tarpaulin storage box 6 in rotation. One side of the tarpaulin 7 is fixed on the rotating shaft 61, and the other side stretches out from the tarpaulin inlet and outlet 60, and remains outside the tarpaulin inlet and outlet 60 all the time. With the rotation of the rotating shaft 61, the tarpaulin 7 can Wound on the rotating shaft 61 and tightly rolled up for storage.

[0038]The tarpaulin 7 is located at the side of the tarpaulin storage box 6 outside and is provided with a clamping rod 71 parallel to the tarpaulin storage box 6, the clampi...

Embodiment 2

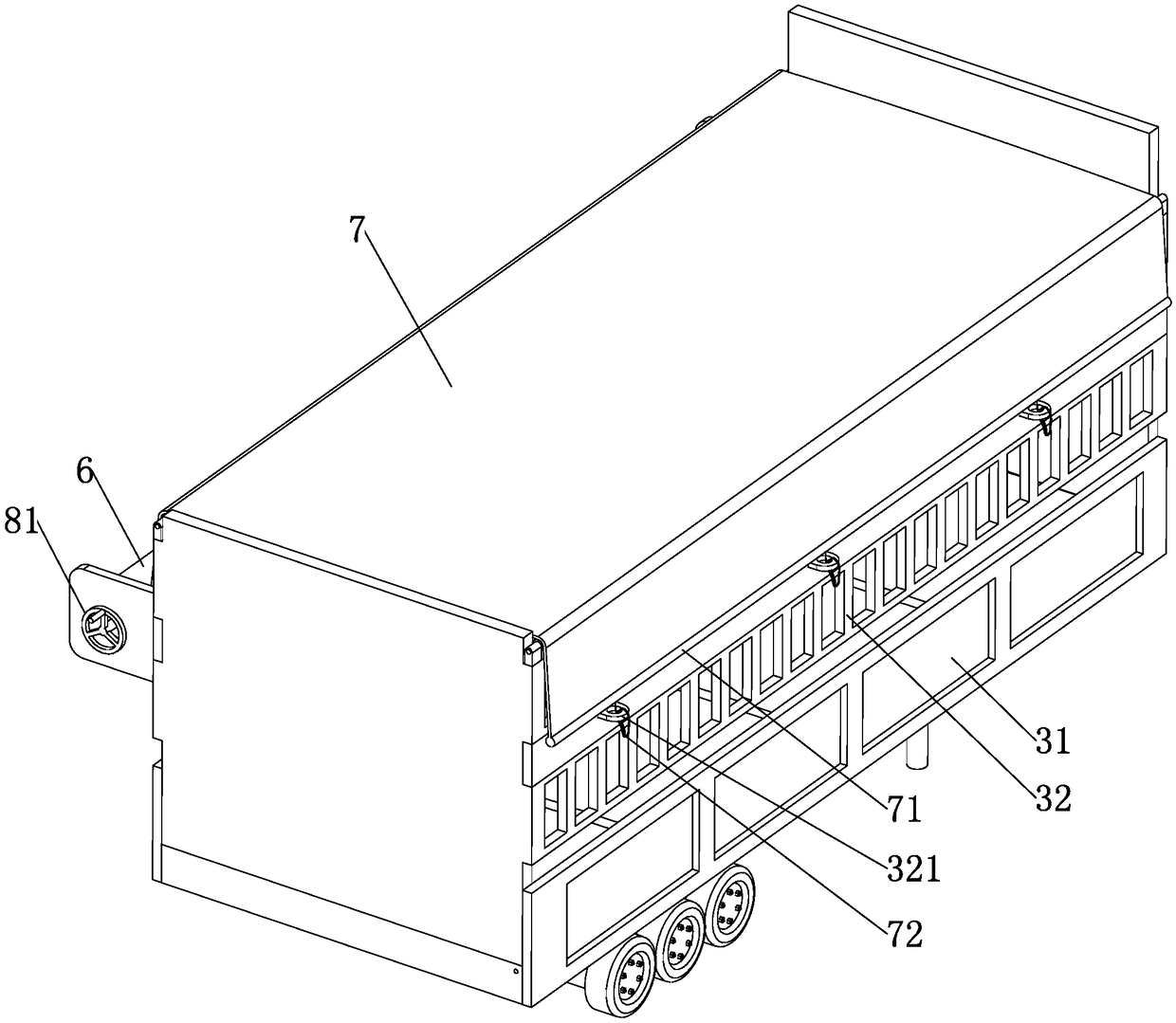

[0042] refer to Figure 4 In this embodiment, the driving device includes an elastic belt 82 connected to the two ends of the rotating shaft 61, and a winding shaft 83 arranged below the two ends of the tarpaulin storage box 6. One end of the elastic belt 82 is connected to the winding shaft 82, and the other end is connected to the The end of the rotating shaft 61 can be elongated and wound on the rotating shaft 61, wherein the two ends of the rotating shaft 61 are connected to the two ends of the tarpaulin storage box 6 through bearings, and extend outwards from the two ends, and the elastic belt 82 is wound on the rotating shaft On the end that 61 protrudes, the natural length of elastic belt 82 is less than the length that tarpaulin 7 protrudes.

[0043] The implementation principle of this embodiment is: in combination with the attached figure 1 and 4 In the initial state, the tarpaulin 7 is shrunk in the tarpaulin storage box 6. When the tarpaulin 7 needs to be used, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com