Multifunctional hand-pressing vacuum generating device and application assembly

A pressing and vacuum technology, which is used in household refrigeration devices, packaging and application under vacuum/special atmosphere, etc., can solve the problems of labor-saving and high-vacuum preservation, and achieve the effect of economical storage and storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

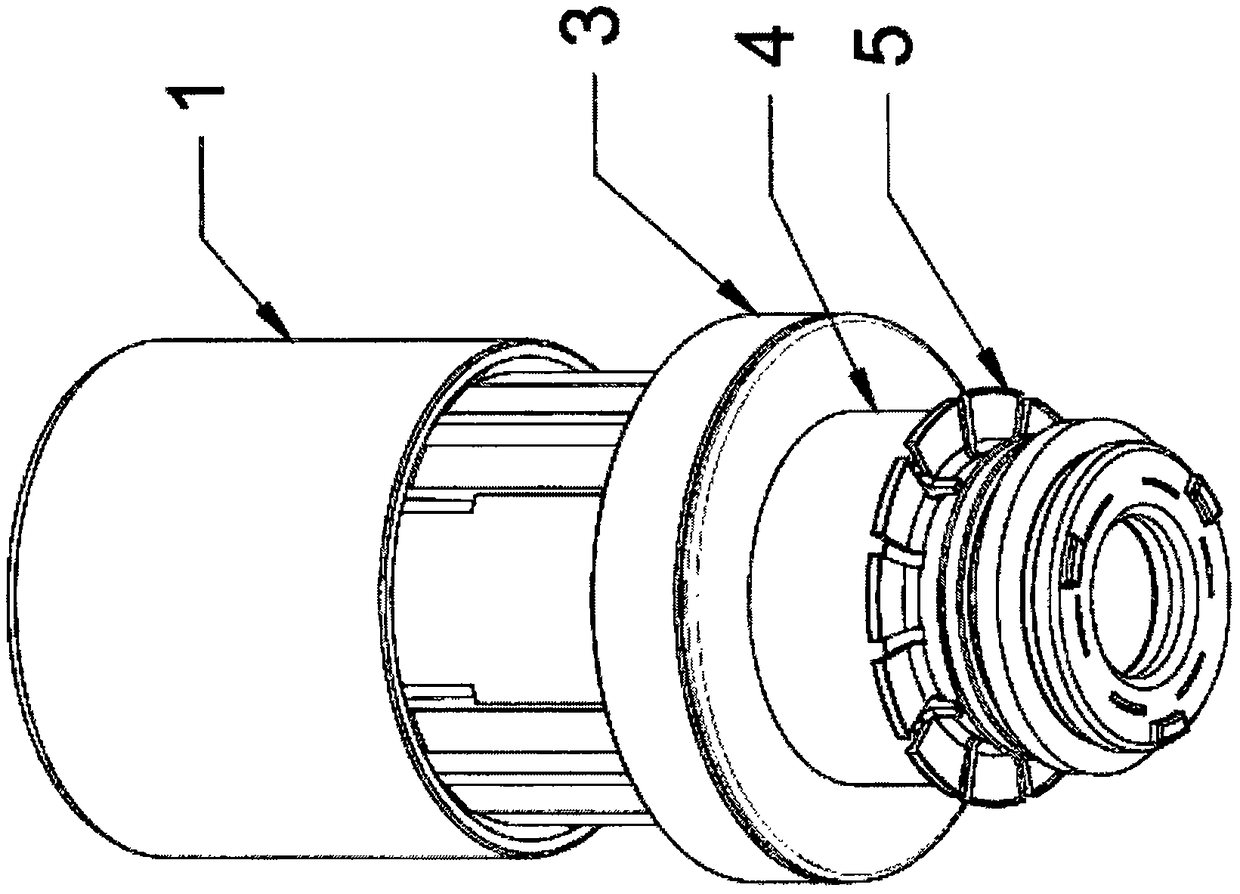

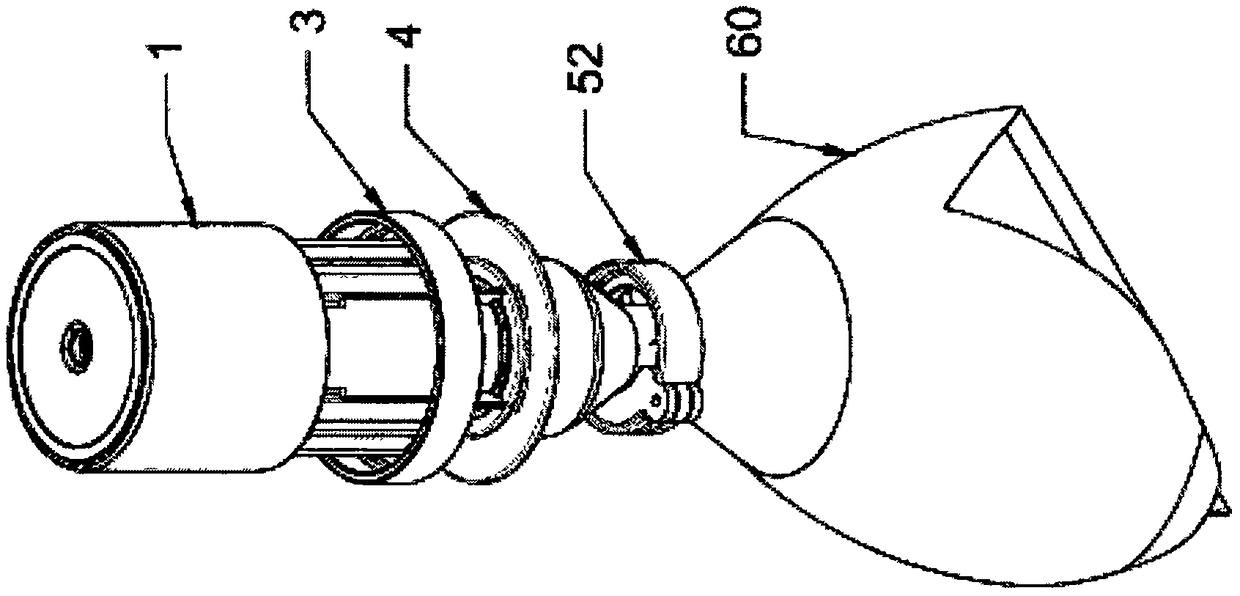

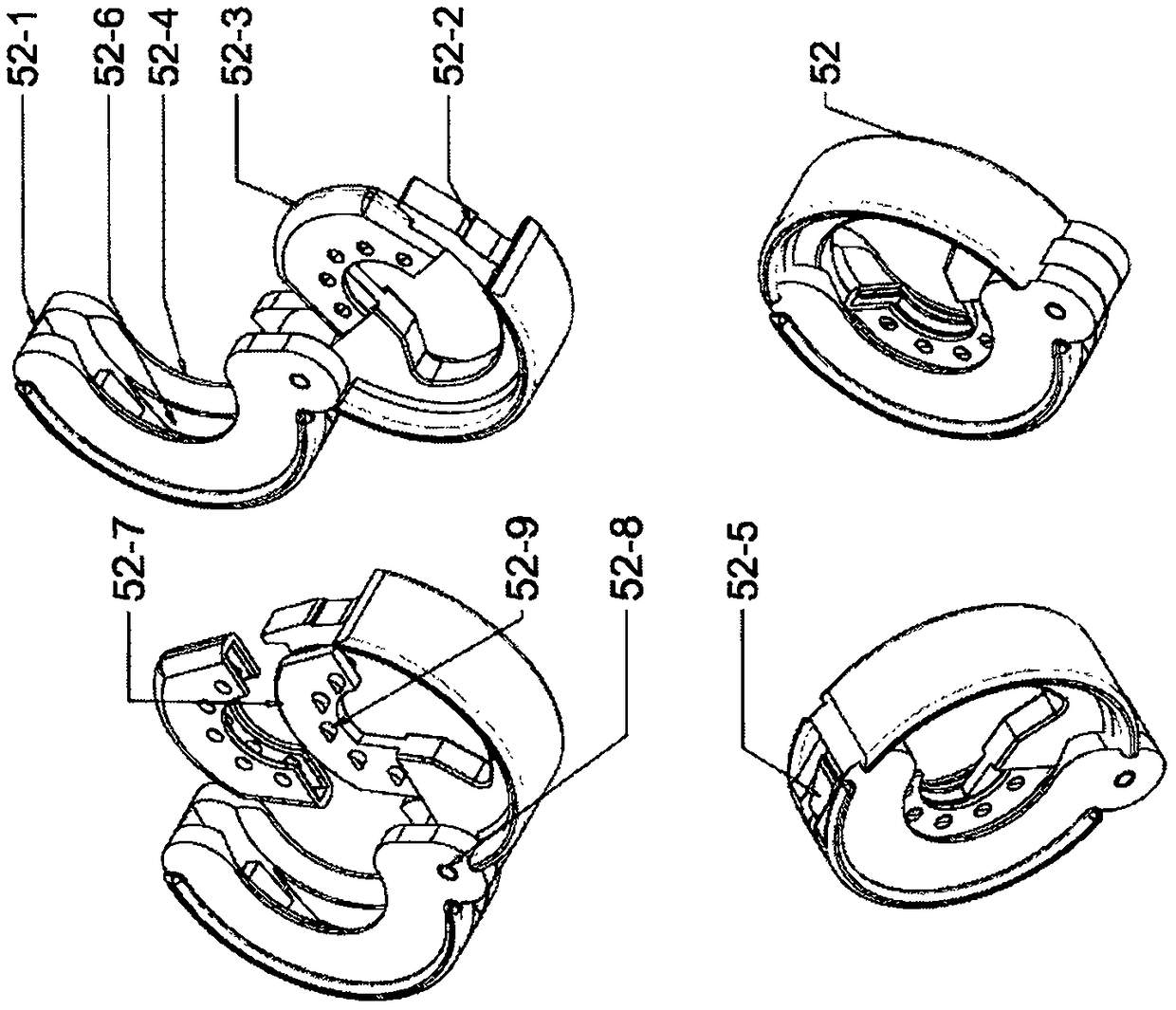

[0437] A press-type high vacuum generating device (20) such as Figure 7 Component combination, embodiment: push-type vacuum generating device 20, please refer to figure 1 , Figure 6 , Figure 7 , Figure 8 The present invention provides a device that is easy to operate and can save labor and generate high vacuum, including a mechanism device main body 3, a hand-pressed upper cover 1 and a spring 10, an airtight O-ring 8-1, and a one-way valve 9-2 , Exhaust one-way valve 9, large piston 2 and spring 11 and airtight O-ring 8-2,8-3, fixed miniature piston center shaft 6 and pressurized exhaust one-way valve 9-1, fixed center Shaft lower cover 7 and vacuum pumping one-way valve 9-3, a total of 5 groups of components are combined into a press-type vacuum pumping device; in addition, in order to provide multi-purpose goals, a main body extension tube 3-23 is added below the mechanism device main body 3, and Install the elastic silicone ring 5 on the lower side of the extensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com