Intellectualized method for preparing purified indigo

An indigo and body technology, applied in the field of indigo preparation, can solve the problems of many steps, complexity, high energy consumption, etc., and achieve the effects of convenient operation, convenient loading and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

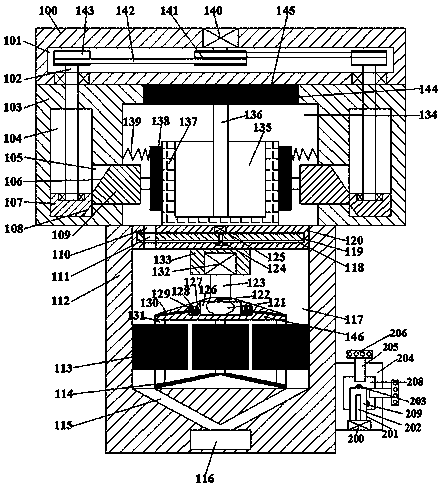

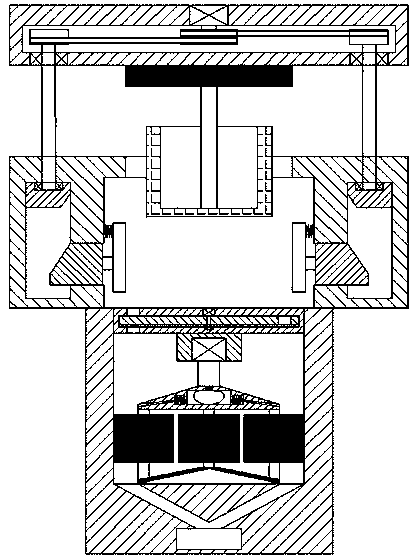

[0018] Such as figure 1 with figure 2As shown, the intelligent method for preparing purified indigo of the present invention uses a distillation extraction device, including a reaction body 112 and a distillation body 103 arranged on the top end surface of the reaction body 112, and inside the reaction body 112 A reaction chamber 117 with an upward opening is provided, and a distillation chamber 134 communicating with the reaction chamber 117 is arranged in the distillation body 103. The two ends of the distillation chamber 134 are symmetrical to the first guide chute 104, the second guide chute 105 is connected between the first guide chute 104 and the distillation chamber 134, and the wall of the distillation chamber 134 There is an opening 144 through it, the top of the distillation body 103 is provided with a power body 100, the power body 100 is provided with a first cavity 101, and the inner wall of the top of the first cavity 101 is embedded with a first motor 140, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com