Testing method for compactness of pre-paved ballast bed

A detection method and technology of compaction degree, applied in the directions of roads, tracks, measuring instruments, etc., can solve the problems of volume deviation of measuring pits and deviation of detection results, so as to reduce the influence error and the probability of test deviation, and the steps are simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] The present invention aims to provide a method for detecting the density of a pre-paved ballast ballast bed to solve the problem that the existing water filling method and sand filling method compactness test method have large deviations in the volume of test pits and are prone to deviations in detection results.

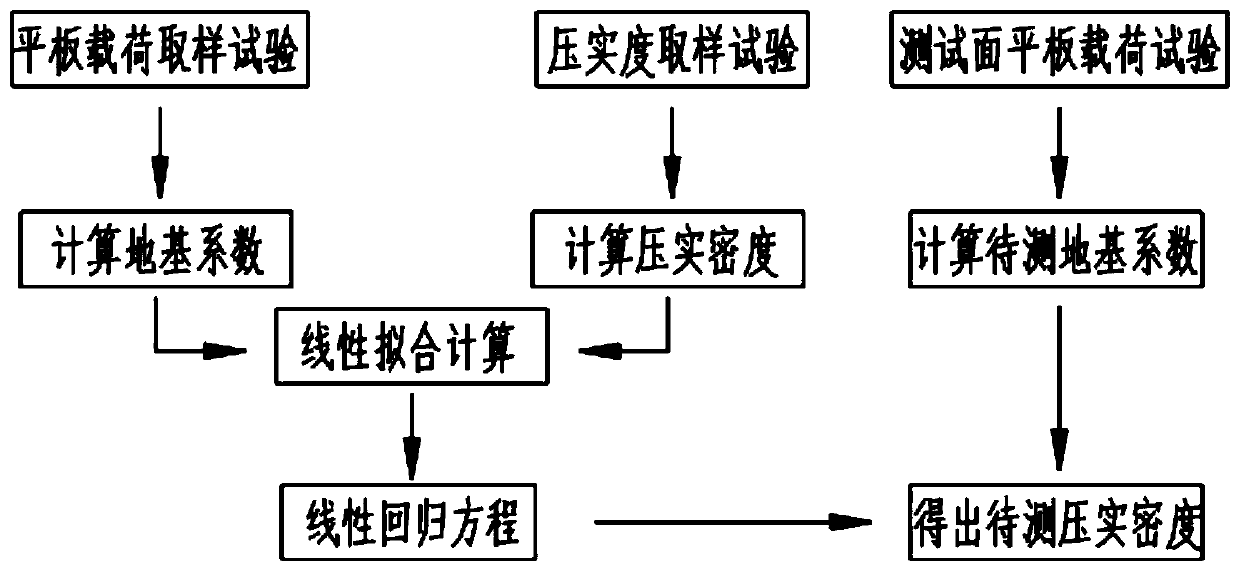

[0039] Please refer to the attached figure 1 , the compactness test method provided by the invention mainly comprises:

[0040] Collect sample data:

[0041] First, take multiple samples from the test site to carry out the plate load test, and record the load intensity σ i and sinkage S i , get the foundation coefficient K i = σ i / S i , is the diameter of the load plate 200;

[0042] At the same time, multiple samples were taken from the corresponding test site for conventional compaction tests, and the same sample was simultaneously tested with multiple compaction test methods and data were collected. In this embodiment, the same sample was tested by ...

Embodiment approach

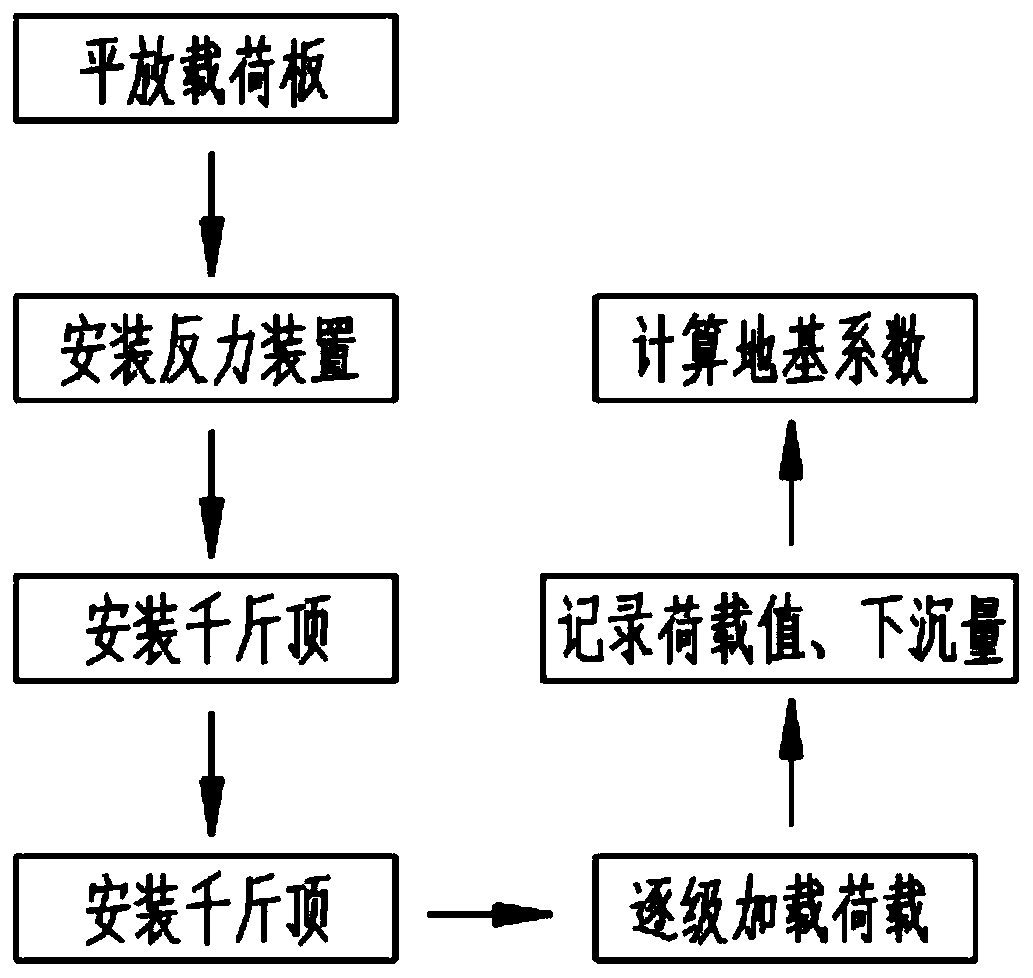

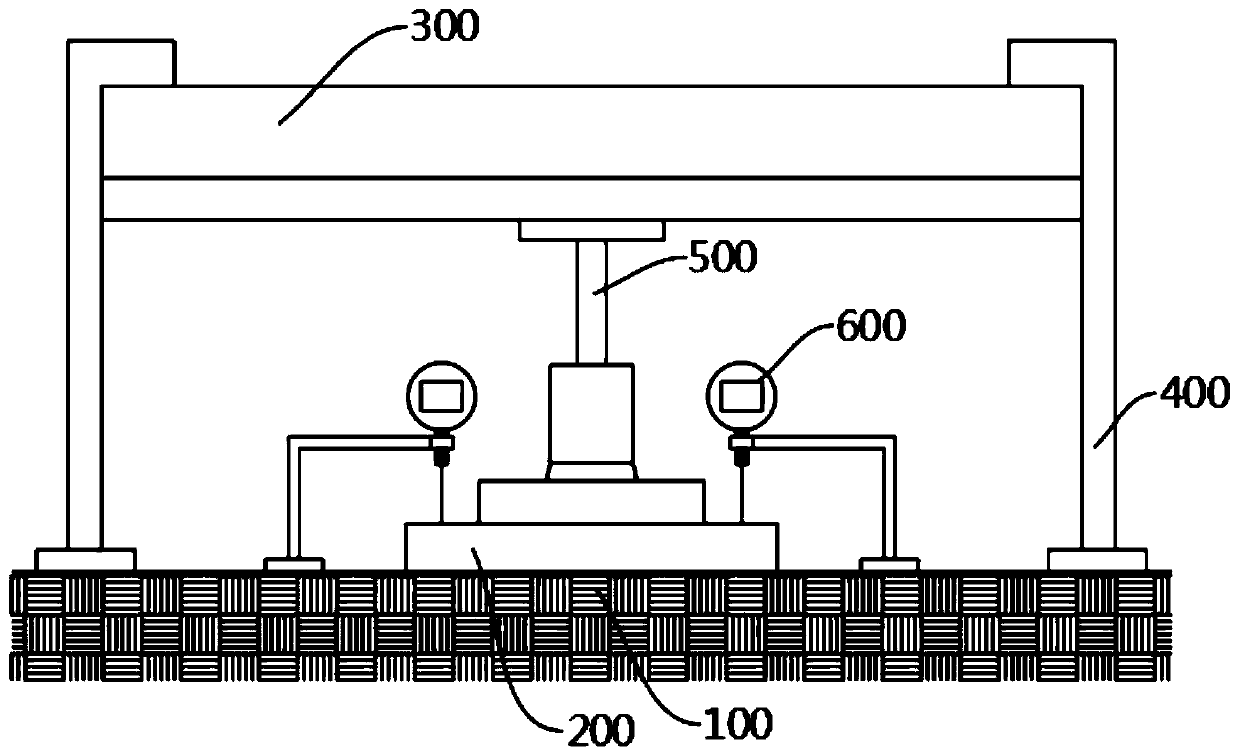

[0049] Wherein, the plate load test of the sample is the same as the plate load test of the test surface 100 . Please refer to the attached figure 2 , the implementation method of the plate load test is as follows:

[0050] 1. If the test surface of the test site is not flat enough, level the test site first, and then place the load plate 200 flat on the test surface 100 so that the load plate 200 is in good contact with the test surface 100 .

[0051] In order to ensure that the load plate 200 is in good contact with the test surface 100, after leveling the site, first lay flexible filler on the test surface 100, then place the load plate 200 flat on the filler, rotate the load plate 200 and hit the load plate 200 to discharge air so that the load plate 200 is in full contact with the test surface 100 . In this embodiment, the flexible filler is gypsum putty, and the surface of the loading plate 200 is coated with an oil film to prevent the gypsum putty from adhering.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com