Starter embedded output shaft assembly

A starter, embedded technology, applied in the direction of engine components, engine starting, machine/engine, etc., to achieve the effect of reducing maintenance costs, simple and reliable assembly, and protection and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

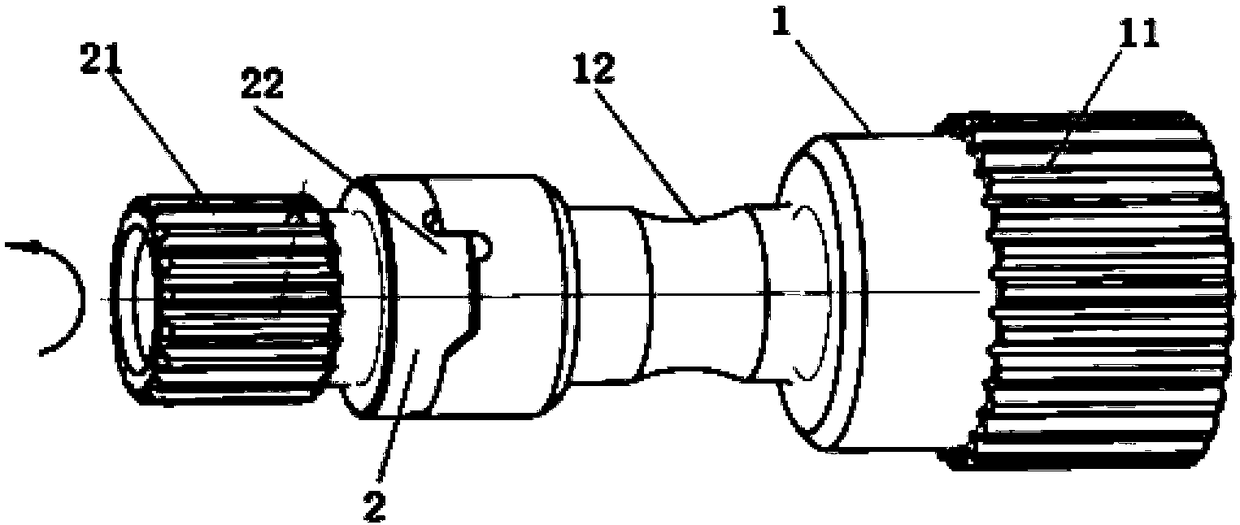

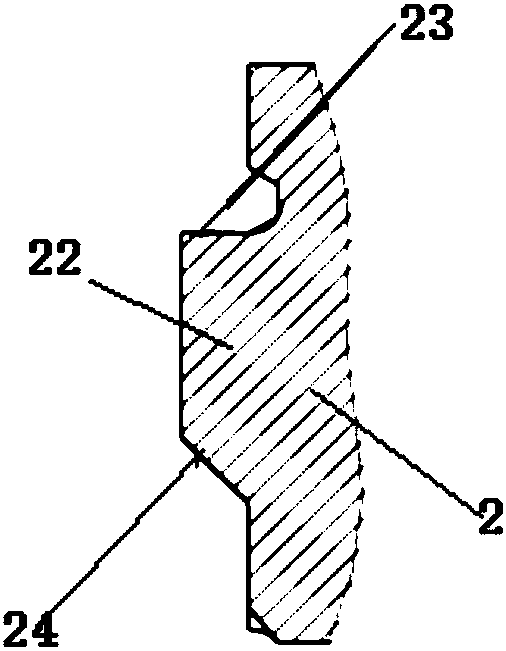

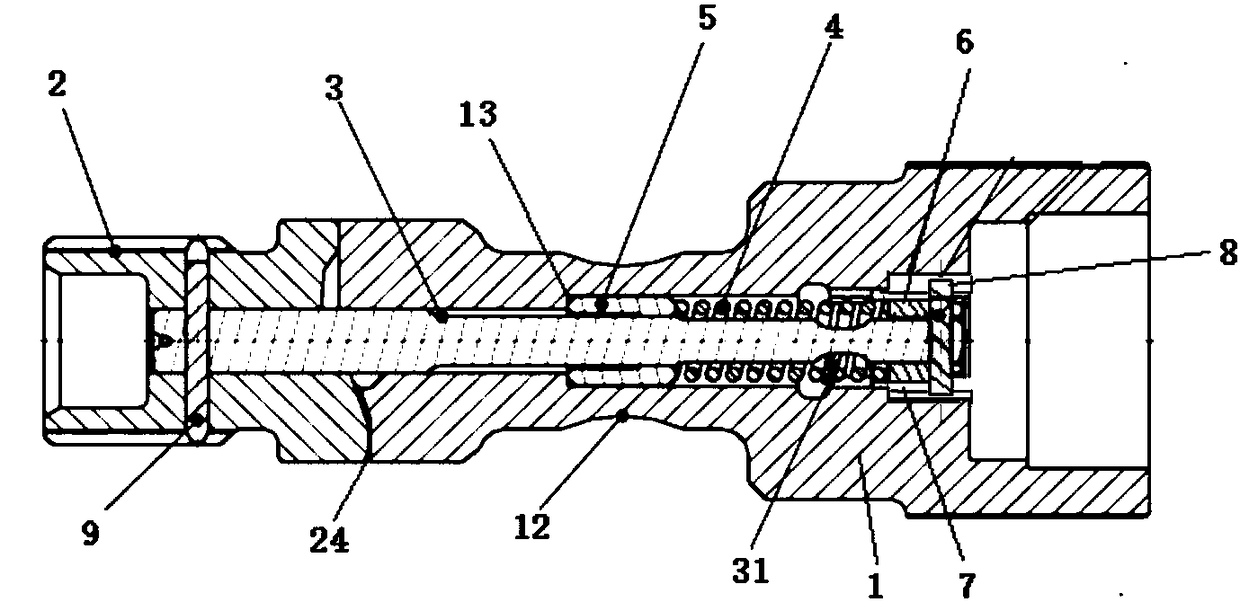

[0012] Example 1 as Figure 1 to Figure 3 As shown, the starter embedded output shaft assembly of this embodiment includes a long output shaft 1, a short output shaft 2 and a thin safety shaft 3, and the tail end of the short output shaft 2 is connected to the starter through the starter connecting gear 21 (Fig. not shown in ) transmission coordination, according to the rotation direction of the starter and the engine, the end face of the front end of the short output shaft 2 is axially protruded and provided with three transmission ladder teeth 22, and each transmission ladder tooth 22 is evenly distributed on the output short shaft 2. On the end face of the front end, each transmission ladder tooth 22 is provided with a right-angled starting surface 23 along one side of the circumference, and a slope separation surface 24 is provided on the other side. The transmission groove is equipped, and the front end of the output long shaft 1 is connected with the engine (not shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com