Diaphragm pump

A diaphragm pump and valve seat technology, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve problems such as difficult processing, reduce processing difficulty, reduce internal space, and facilitate rapid bulging and deflation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

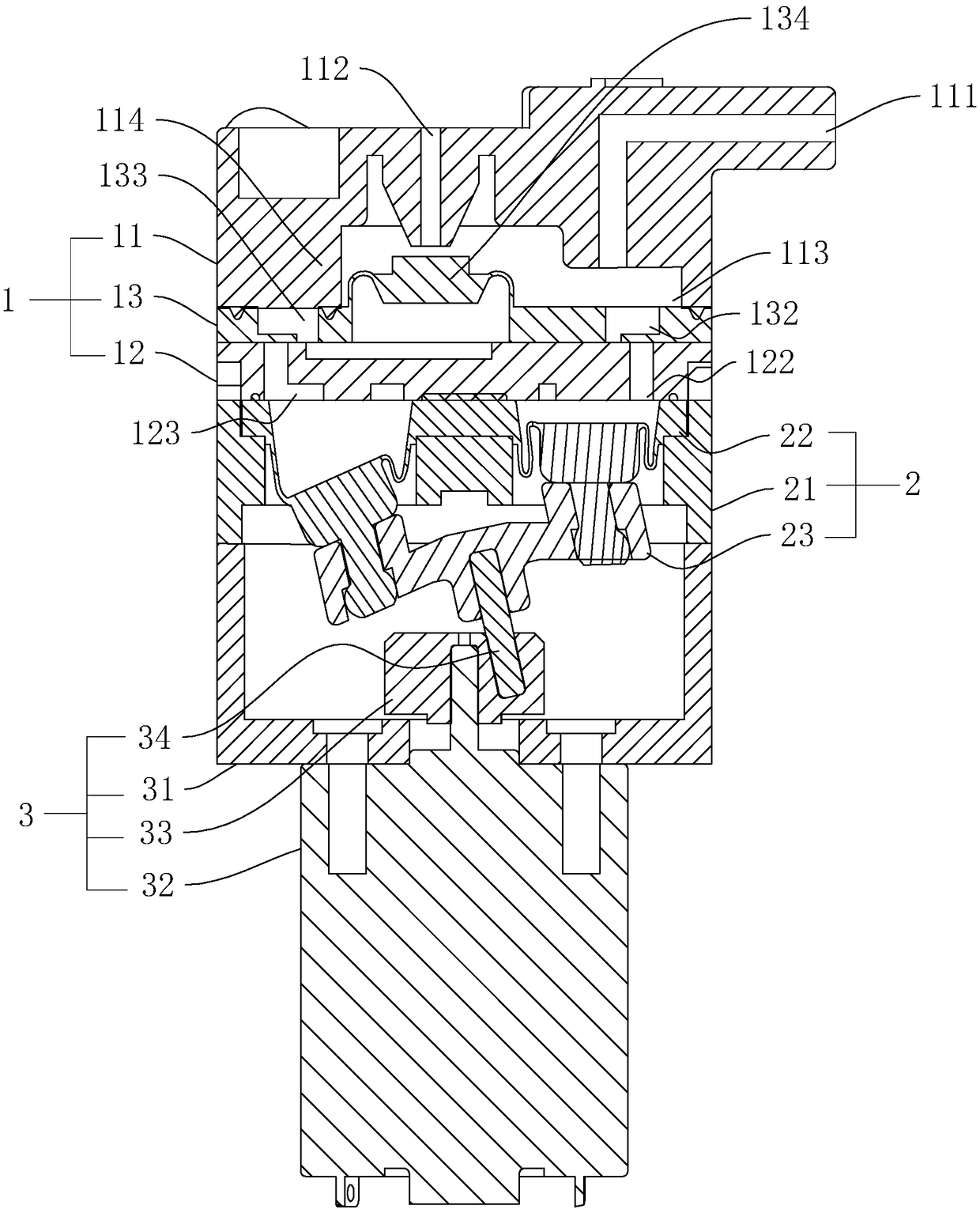

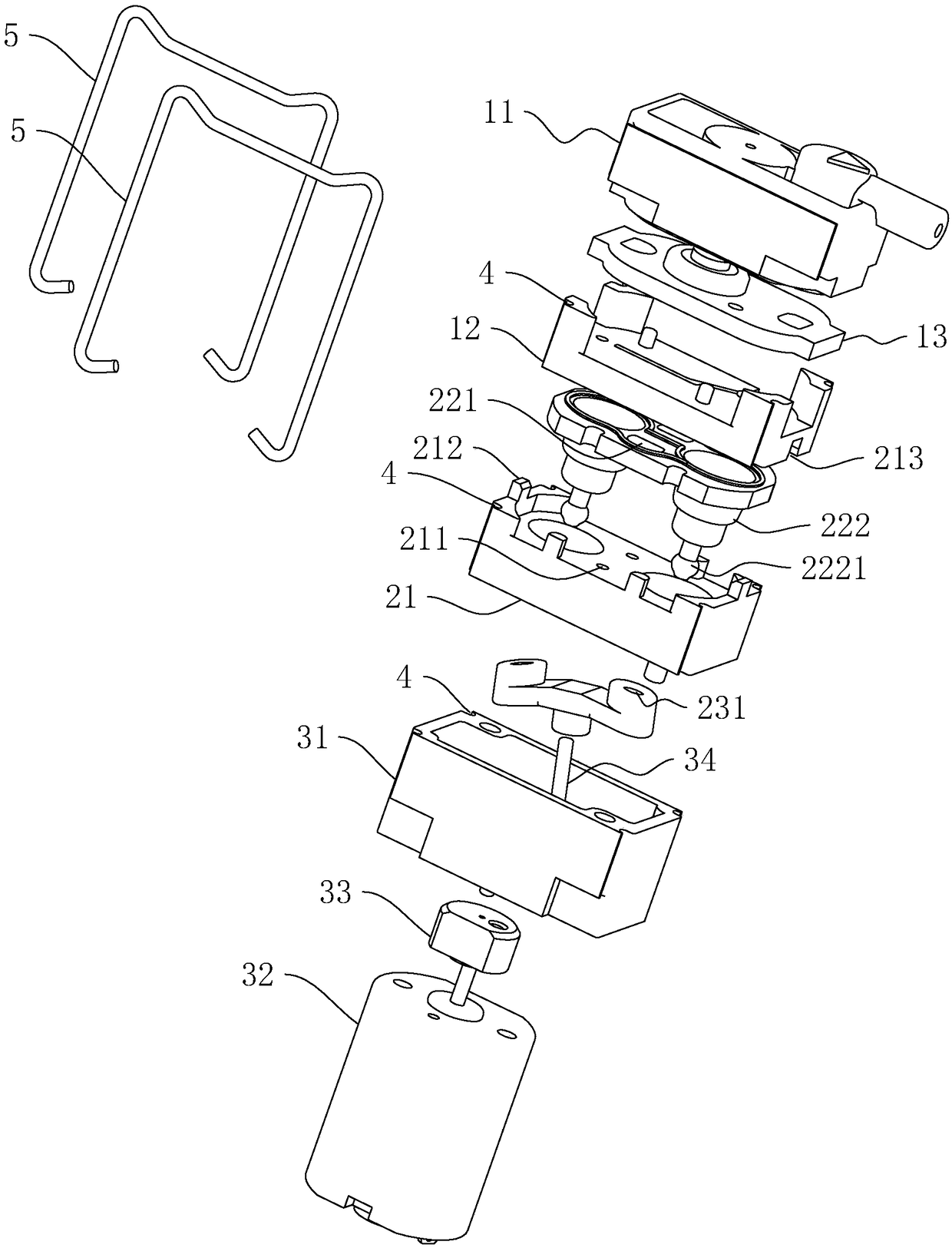

[0037] A diaphragm pump such as figure 1 As shown, it includes an upper cover assembly 1 , a piston assembly 2 and a drive assembly 3 connected sequentially from top to bottom.

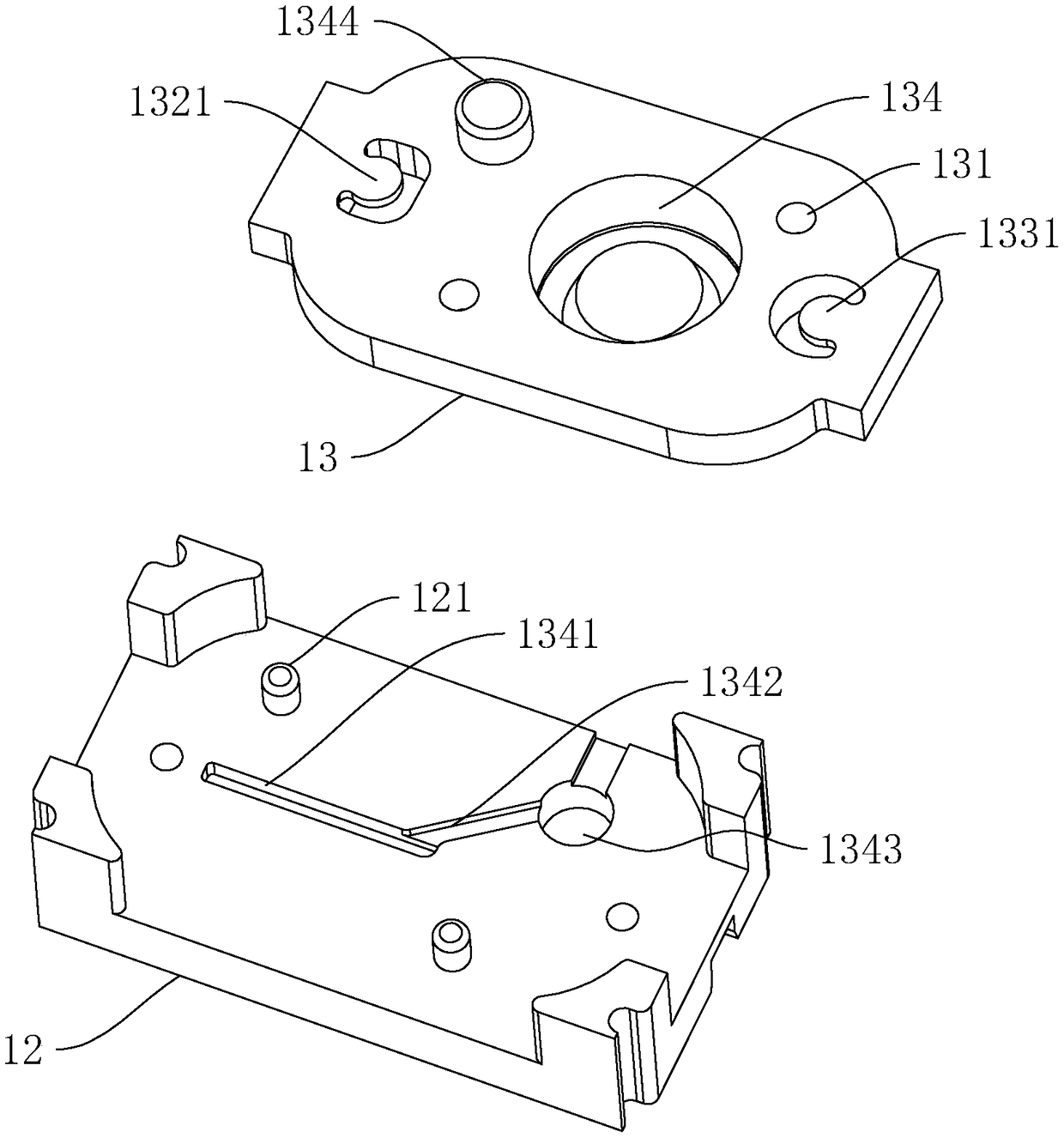

[0038] like figure 1 , 2 As shown, the upper cover assembly 1 includes an upper cover body 11, a valve seat 12 and a valve plate 13, the valve plate 13 is made of rubber material and is arranged between the valve seat 12 and the upper cover body 11, and the upper end of the valve seat 12 is provided with The valve cavity that matches the shape of the valve plate 13 has a positioning protrusion 121 extending upward in the valve cavity. The valve plate 13 is provided with a positioning hole 131 for the insertion of the positioning protrusion 121. Through the positioning protrusion 121 and the positioning hole 131 Cooperating, the installation of the valve plate 13 can be made more stable.

[0039] Further, in order to ensure that the installation position of the valve plate 13 is accurate and reduce ...

Embodiment 2

[0051] A diaphragm pump such as Figure 4 As shown, the difference from Embodiment 1 is that the valve seat 12 is provided with a positioning column 6 extending toward the valve plate 13 and placed in the pressure relief air bag 134, through which the positioning column 6 can prevent the pressure relief air bag 134 from being in a dry state. , reducing the internal space of the pressure relief airbag 134 is conducive to the rapid inflation and deflation of the pressure relief airbag 134.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com