Lighting device

A lighting device and low beam technology, applied in the field of lighting, can solve the problems of rising temperature of vehicle lamps, reducing service life, slow heat dissipation, etc., and achieving the effects of reducing light loss, improving efficiency, and dispersing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

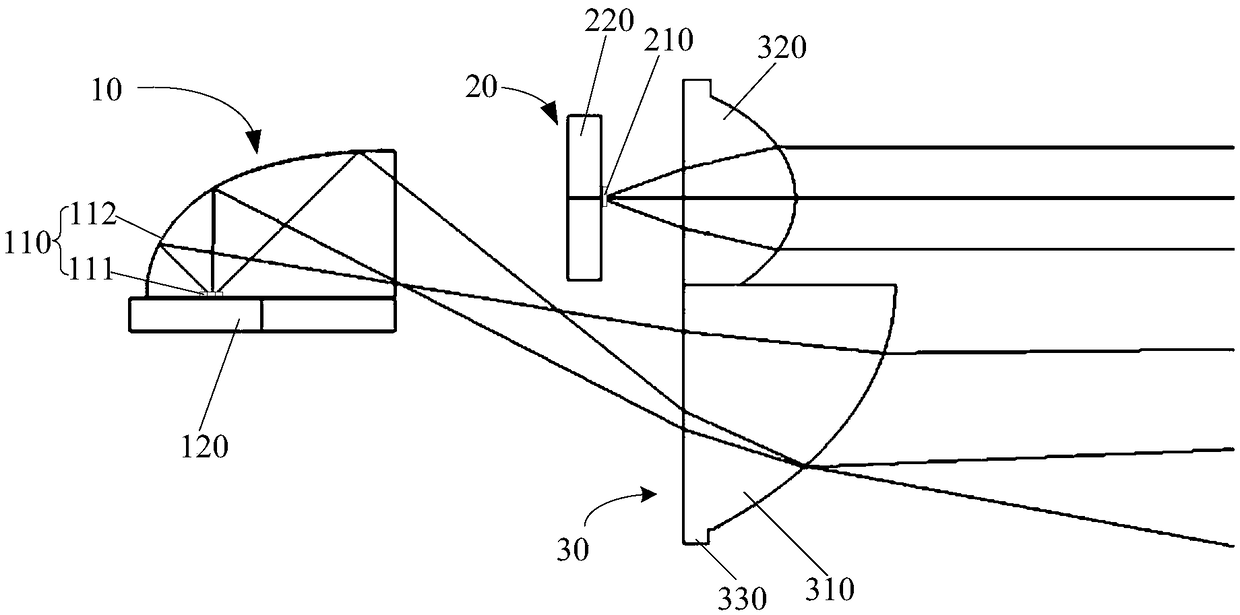

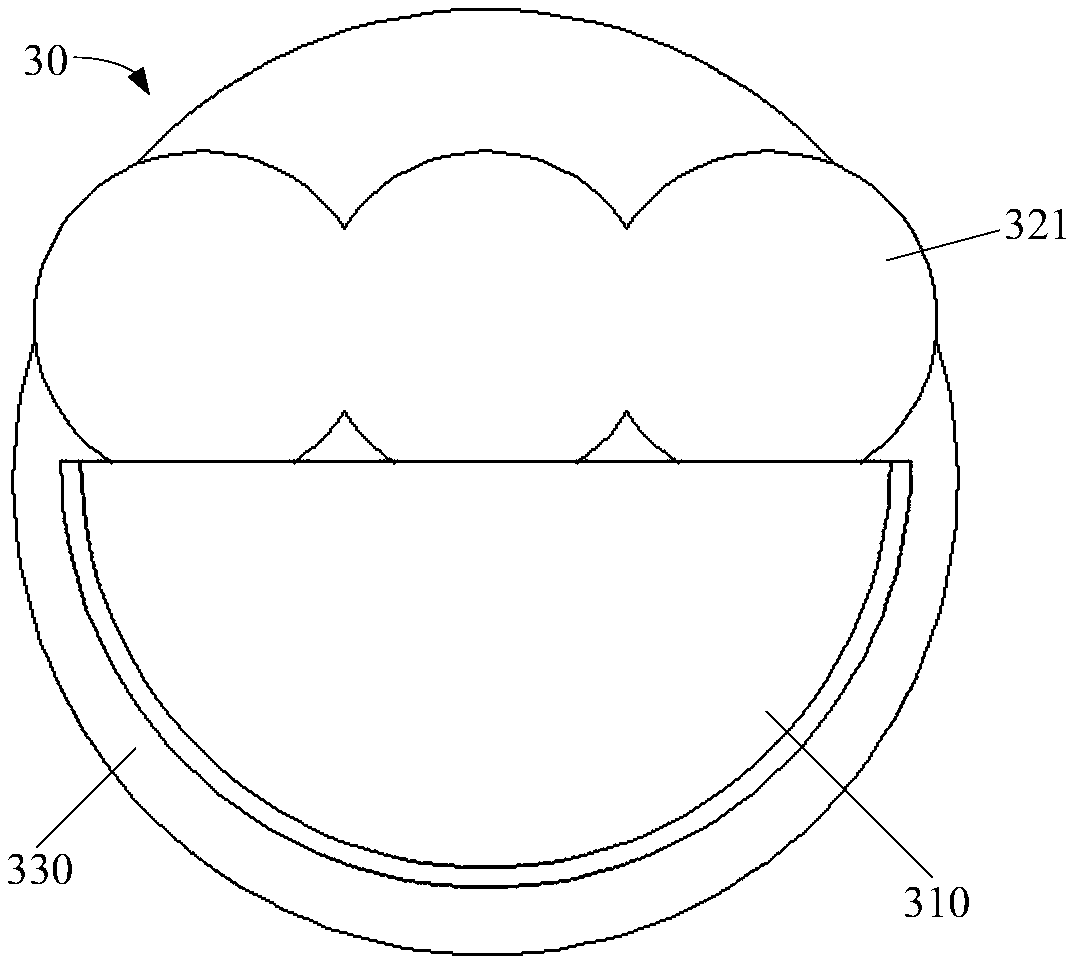

[0024] Such as figure 1 As shown, the present invention provides a lighting device, comprising:

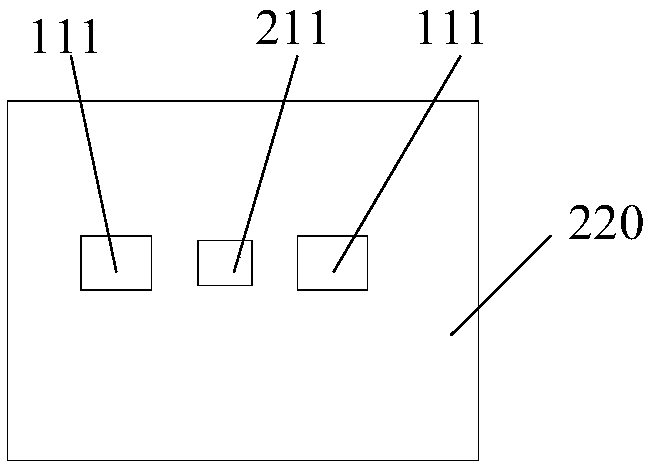

[0025] The low beam module 10 includes a low beam light source and a first heat dissipation unit 120 , the low beam light source includes at least one LED light source 111 and a reflective bowl 112 corresponding to the LED light source 111 . Specifically, in this embodiment, the first heat dissipation unit 120 is located under the low beam light source, and the LED light source 111 can be connected to the first heat dissipation unit 120 through the substrate to quickly dissipate heat. Of course, the first heat dissipation unit 120 can also be located at the low beam. On one side of the light source, the heat is exported through the heat-conducting substrate for rapid heat dissipation. Usually there are 2 to 4 LED light sources 111 in the low-beam light source, and of course ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com