Automatic ice ball cutting device

An ice hockey and automatic technology, applied in ice manufacturing, ice storage/distribution, lighting and heating equipment, etc., can solve the problems of low cleanliness of ice cubes, high production switching costs, inconvenient operation, etc., and avoid unreasonable settings , Guarantee the processing quality and avoid the effect of excessive leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

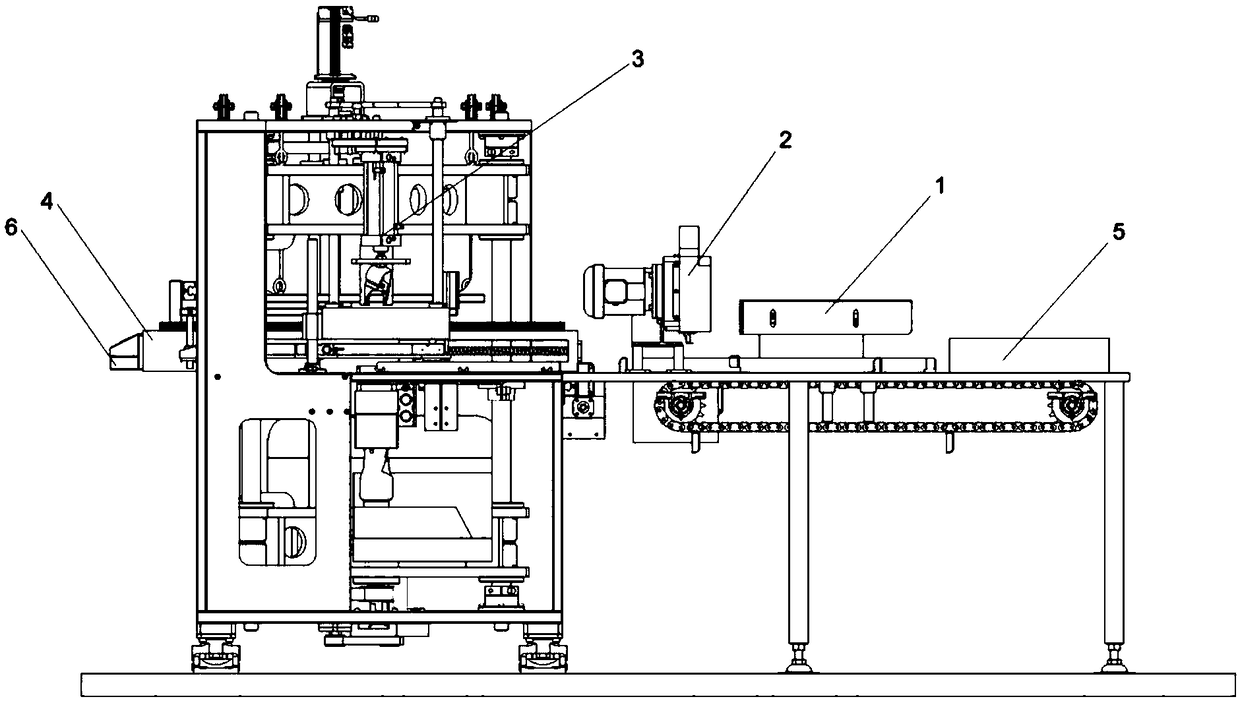

[0034] like figure 1 As shown, an ice hockey automatic chipping device includes a control system, a thickness detection mechanism 1, an ice cube flattening mechanism 2, a chipping mechanism 3, a quality detection mechanism 4, and an ice outlet 6, which are arranged in sequence. The thickness detection mechanism 1, the ice cube flattening mechanism 2, the ball cutting mechanism 3, and the quality detection mechanism 4 are connected; the thickness detection mechanism 1 is provided with a thickness detection sensor for detecting the thickness of the thinnest part of the ice cube 5 to be processed and the overall thickness, and feedback the detection results to the control system, and the control system sets and adjusts other mechanisms according to the feedback information. like Figure 4 As shown, the ice cube leveling mechanism 2 includes a leveling machine 9, a height adjustment mechanism 10, and an ice pushing mechanism 11. The height adjustment mechanism 10 is connected wit...

Embodiment 2

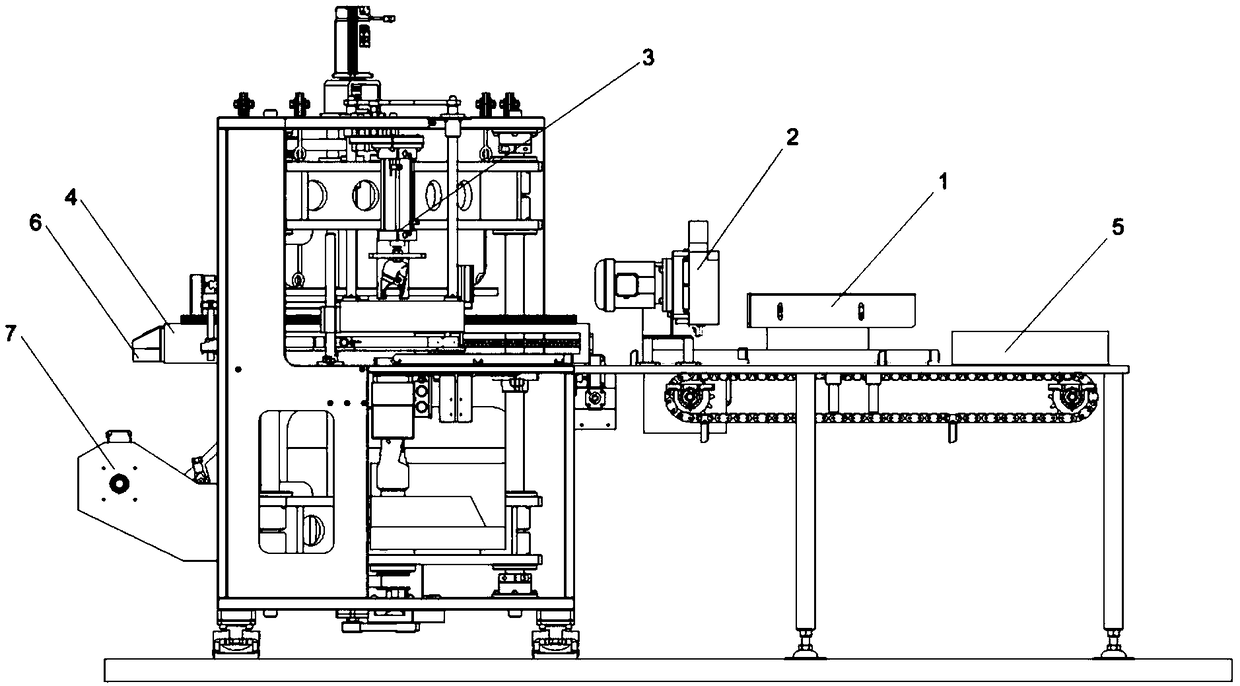

[0050] This embodiment 2 is the same as the overall technical scheme of embodiment 1, and the difference is:

[0051] like figure 2 As shown, the flattening mechanism and the chipping mechanism 3 in this embodiment 2 are further provided with a crushed ice collecting device, which is used to collect the crushed ice or ice cubes generated in the flattening mechanism and the ball-cutting mechanism 3 . The ice hockey automatic chipping device is also provided with an ice cube crushing mechanism 7, which is arranged on the lower side of the ice outlet 6, and its inlet is connected to the ice cube leveling mechanism 2 and the ice cube crushing mechanism 3. The crushed ice collection device, the defective product collection mechanism of the quality inspection mechanism 4, the outlet is connected to the next process of processing crushed ice or the device for collecting crushed ice. The ice cube crushing mechanism 7 is mainly composed of a drum with teeth. The remaining ice cubes a...

Embodiment 3

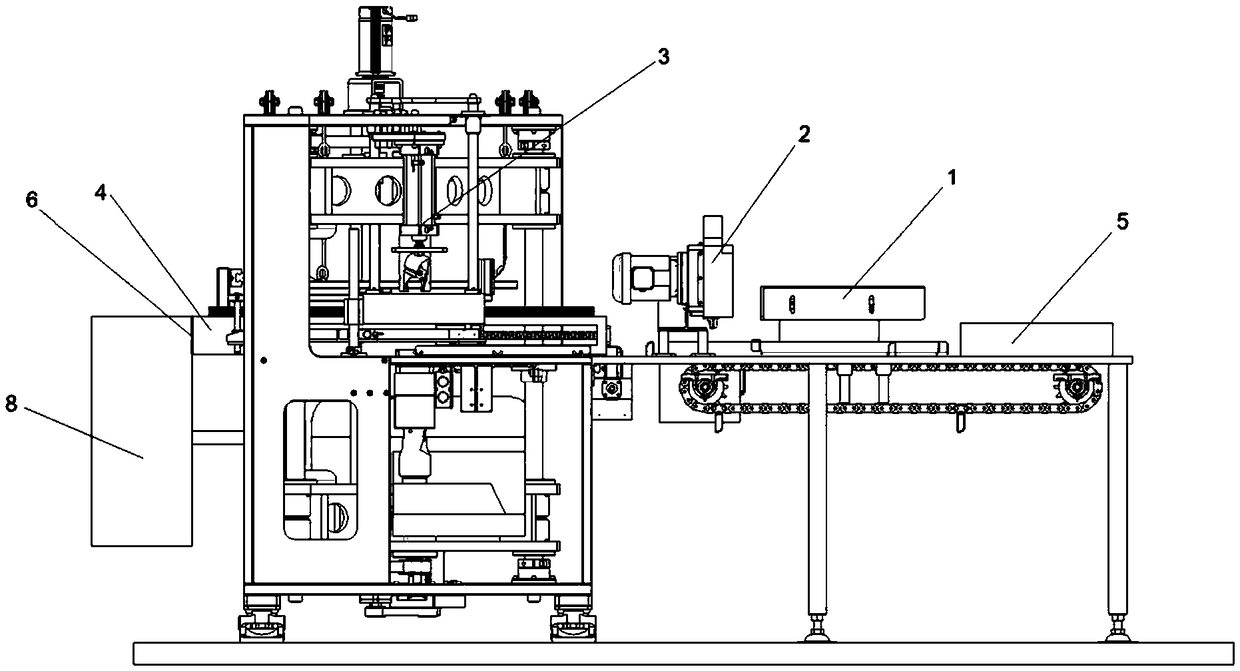

[0053] This embodiment 3 is the same as the overall technical scheme of embodiment 1, and the difference is:

[0054] like image 3 As shown in the present embodiment 3, the ice hockey automatic chipping device is also provided with an automatic packaging mechanism 8, and the automatic packaging mechanism 8 is directly connected to the ice outlet 6, and the newly processed ice hockey is immediately bagged separately, Vacuum and seal to prevent the ice hockey from melting, further simplify the production process and improve the quality of the ice hockey.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com