Firework paper cylinder cutting device

A cutting device and paper tube technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve problems such as difficult simultaneous cutting of multiple firework paper tubes, a large number of potential safety hazards, etc., to improve cutting efficiency and reduce Cuts, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

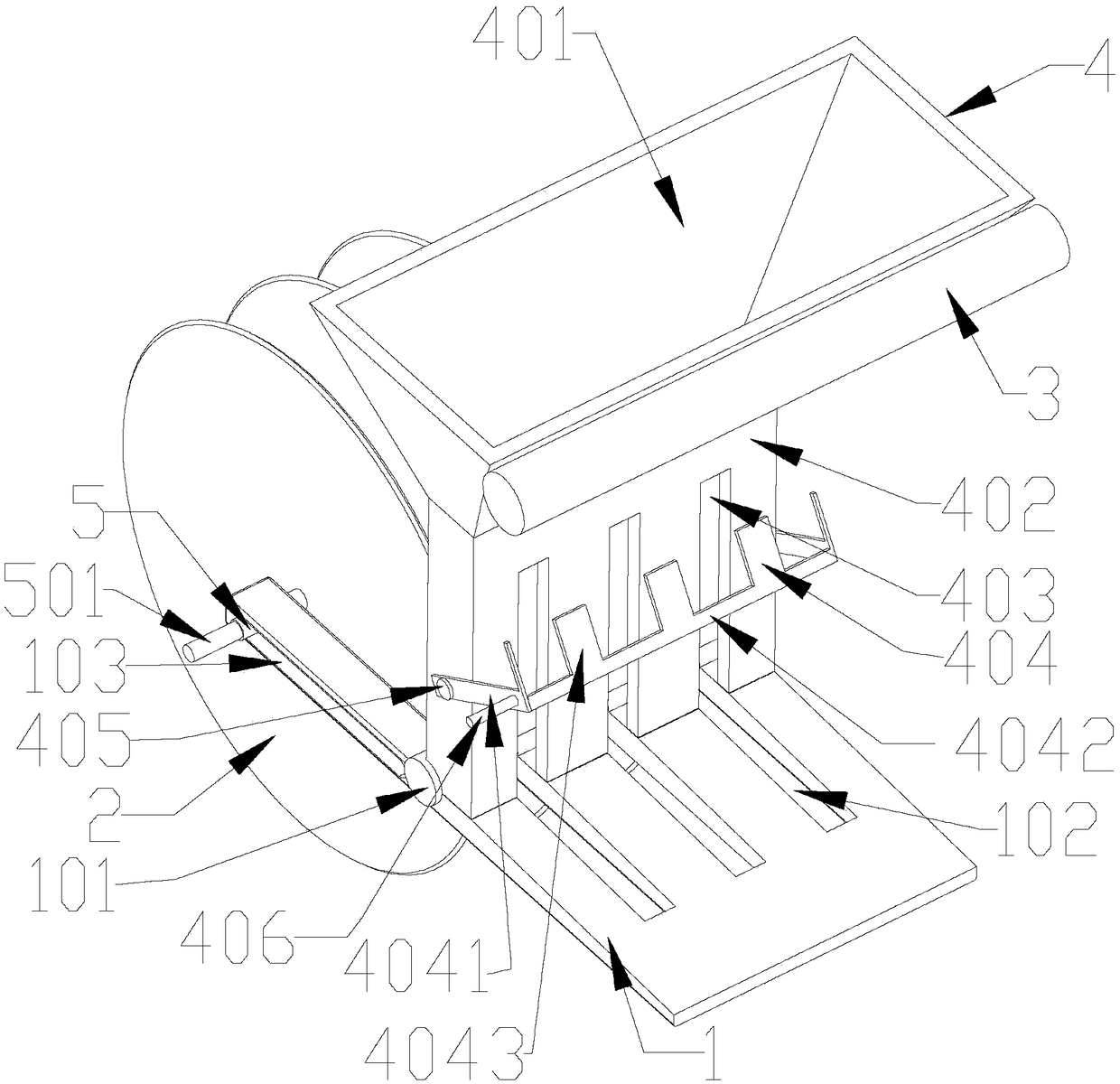

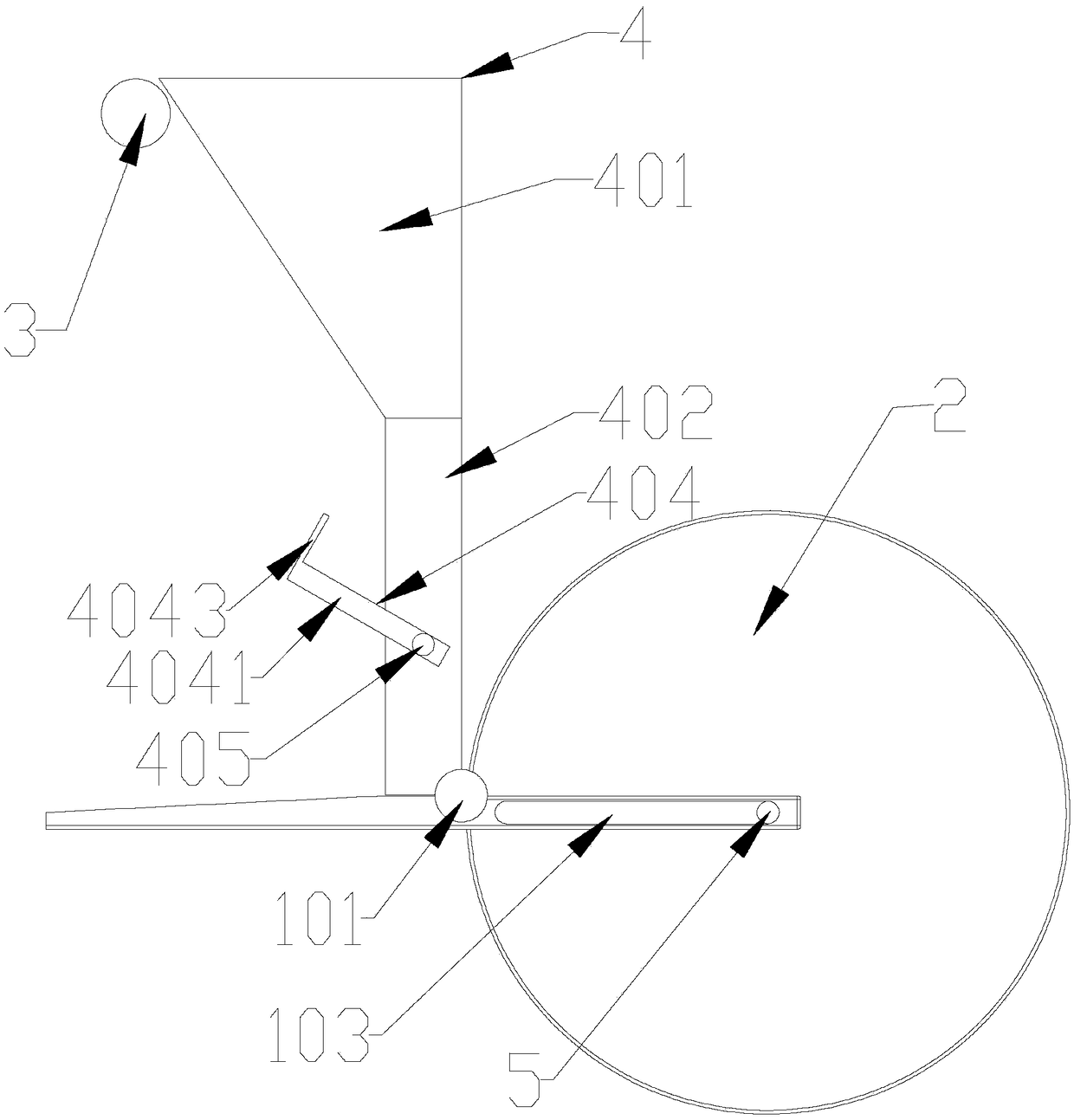

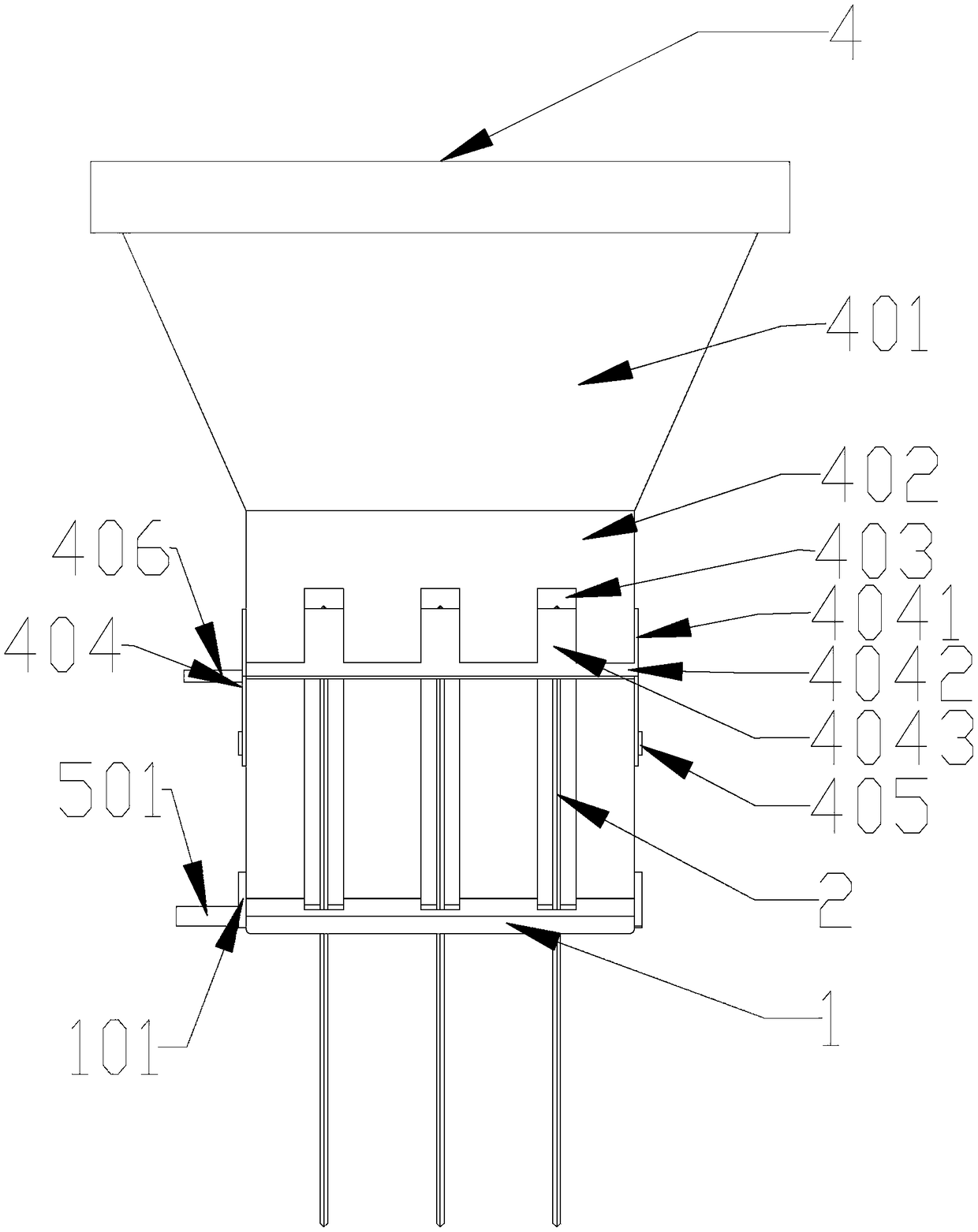

[0019] Example 1: see Figure 1 to Figure 4 , when the applicant uses the cutting device in the technical solution of the present application, he only needs to open the transmission mechanism, and the firework paper tube will be transferred to the guide structure at the upper end of the storage mechanism under the transmission of the transmission mechanism. Each side wall is composed of inclined surfaces, that is, the width of the guide structure is a funnel structure that gradually decreases from top to bottom, so when the firework paper tube enters the guide structure through the transmission mechanism, the firework paper tube will roll under the guidance of the inclined surface. Enter the accommodating cavity through the second through hole between the guide structure and the accommodating cavity; after the multiple firework paper tubes are filled in the accommodating cavity, grasp the first handle and rotate the outer side wall of the accommodating cavity circumferentially....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap