Ultrahigh pressure hydraulic seal test device and method

A technology of hydraulic sealing and testing device, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the acceleration and deceleration rate of fluid, etc. Convenience, wide availability, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

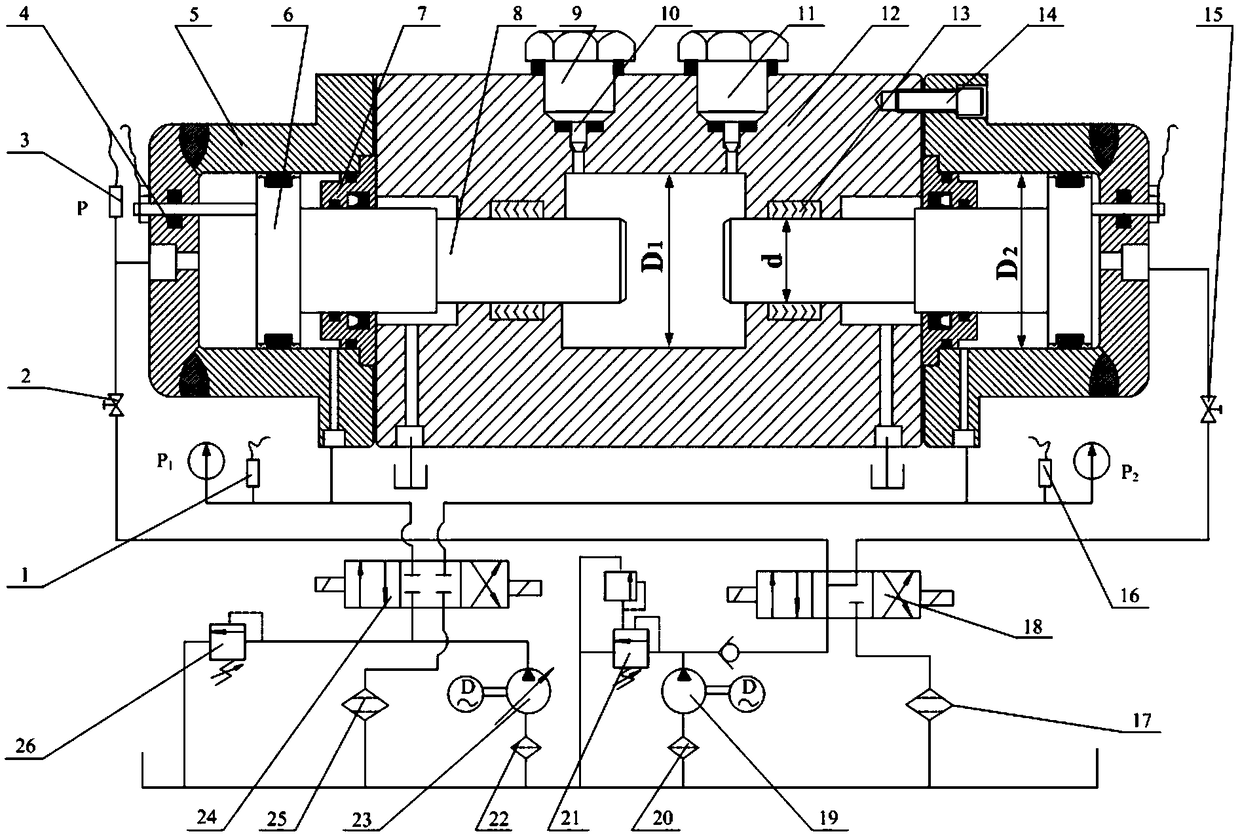

[0027] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0028] The ultra-high pressure hydraulic seal test device of the present invention mainly consists of an overpressure cylinder 12, a loading cylinder, a pressurized loading system and a dragging drive system; the two loading cylinders are respectively fixed on the two ends of the overpressure cylinder 12, One of the two loading cylinders is provided with a sensing device 4 for detecting the operating position of the piston. The pressurized loading system and the dragging drive system are respectively connected with two loading cylinders;

[0029] An axial through hole is processed on the overpressure cylinder 12, and the through hole is composed of 5 sections of holes with different diameters, and the hole in the middle part has a diameter of D 1 There are radial oil leakage holes on the lower wall of the holes at both ends, and there are holes on the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com