A three-dimensional macroscopic porous graphite phase carbon nitride photocatalyst and its preparation and application

A phase carbon nitride light, porous graphite technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of hindering the application of powder catalysts and restricting graphite phase carbon nitride powder catalysts Application prospects, low reuse rate, etc., to achieve good controllability, large specific surface area and visible light absorption performance, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

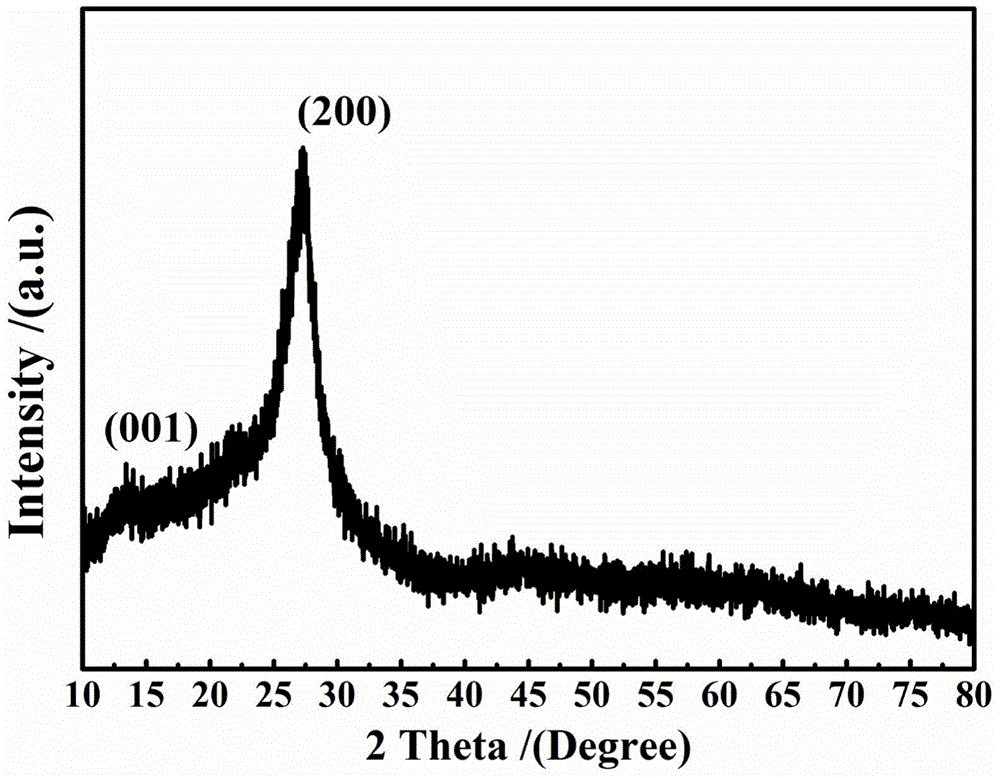

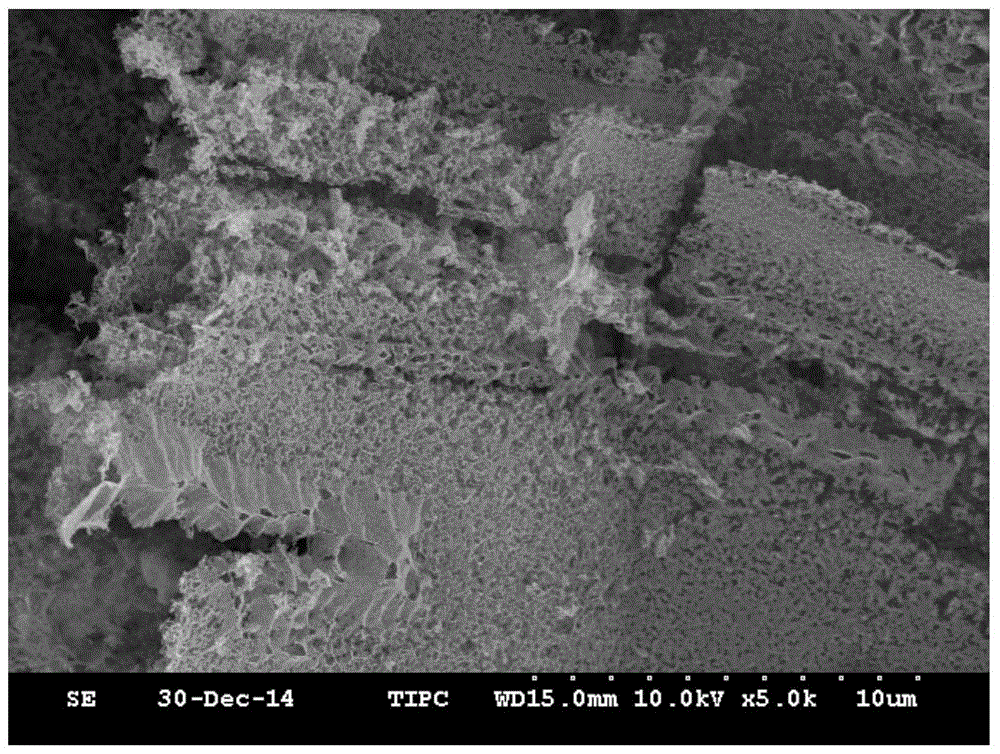

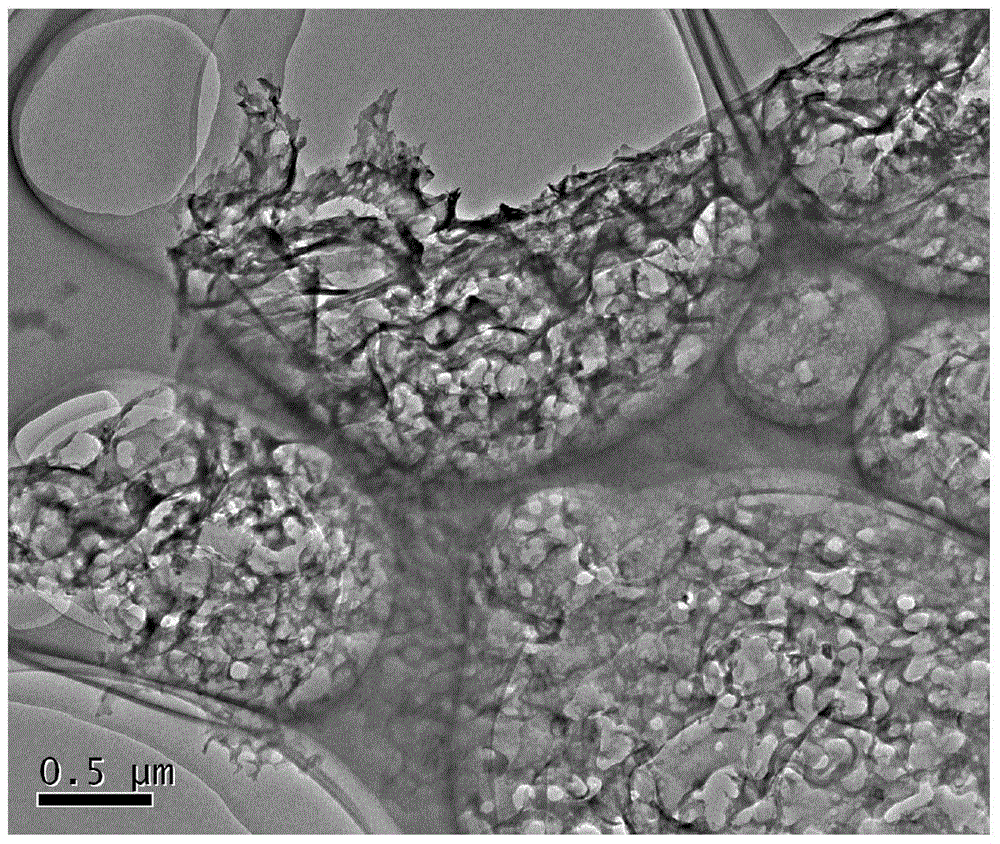

[0027] Soak a cuboid melamine sponge with a mass of ~100mg and a size of approximately 4cm×1.5cm×1.5cm in 30mL of 0.5g mL -1 In the urea aqueous solution, the mass ratio of immersion is about 1:150. After 10min, the saturated sponge is taken out, and after freeze-drying, the melamine sponge loaded with urea is dried in N 2 Calcined at 550°C for 4h and cooled to room temperature, a three-dimensional macroscopic porous graphite phase carbon nitride catalyst was prepared. X-ray powder diffraction (XRD) characterization proves that this material is the carbon nitride of graphitic phase, see figure 1 shown. Scanning (SEM) and transmission electron microscopy (TEM) can observe the obvious porous structure, see figure 2 and 3 shown. N 2 The adsorption test also proves that it has an obvious stacked pore structure, and its specific surface area is calculated by BET method to be 78m 2 g -1 ,See Figure 4 shown. The ultraviolet-visible absorption spectrum proves that the three...

Embodiment 2

[0029] Soak a cuboid melamine sponge with a mass of ~100mg and a size of approximately 4cm×1.5cm×1.5cm in 30mL of 0.1g mL -1 In the melamine aqueous solution, the mass ratio of immersion is about 1:30, after 10min, take out the absorbent saturated sponge, after freeze-drying, dry the melamine sponge loaded with melamine in N 2 Calcined at 600°C for 1 h, cooled to room temperature, and a three-dimensional macroscopic porous graphite carbon nitride catalyst was prepared. The specific surface is about 40m 2 g -1 , the absorption sideband is about 700nm.

Embodiment 3

[0031] Soak a cuboid melamine sponge with a mass of ~100mg and a size of about 4cm×1.5cm×1.5cm in 30mL 0.3g mL -1 In the aqueous solution of thiourea, the mass ratio of immersion is about 1:90. After 10min, the saturated sponge is taken out. After freeze-drying, the melamine sponge loaded with thiourea is dried in N 2 Calcined at 500°C for 2 hours and cooled to room temperature, a three-dimensional macroscopic porous graphite carbon nitride catalyst was prepared. The specific surface is about 55m 2 g -1 , the absorption sideband is about 700nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com