Method for detecting bending mechanical property of test sample

A bending and mechanical technology, applied in the field of testing the bending mechanical properties of samples, can solve the problems of inaccurate test data, lack of stability, no fixation, etc., achieve strong operability, low cost, and prevent sample deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

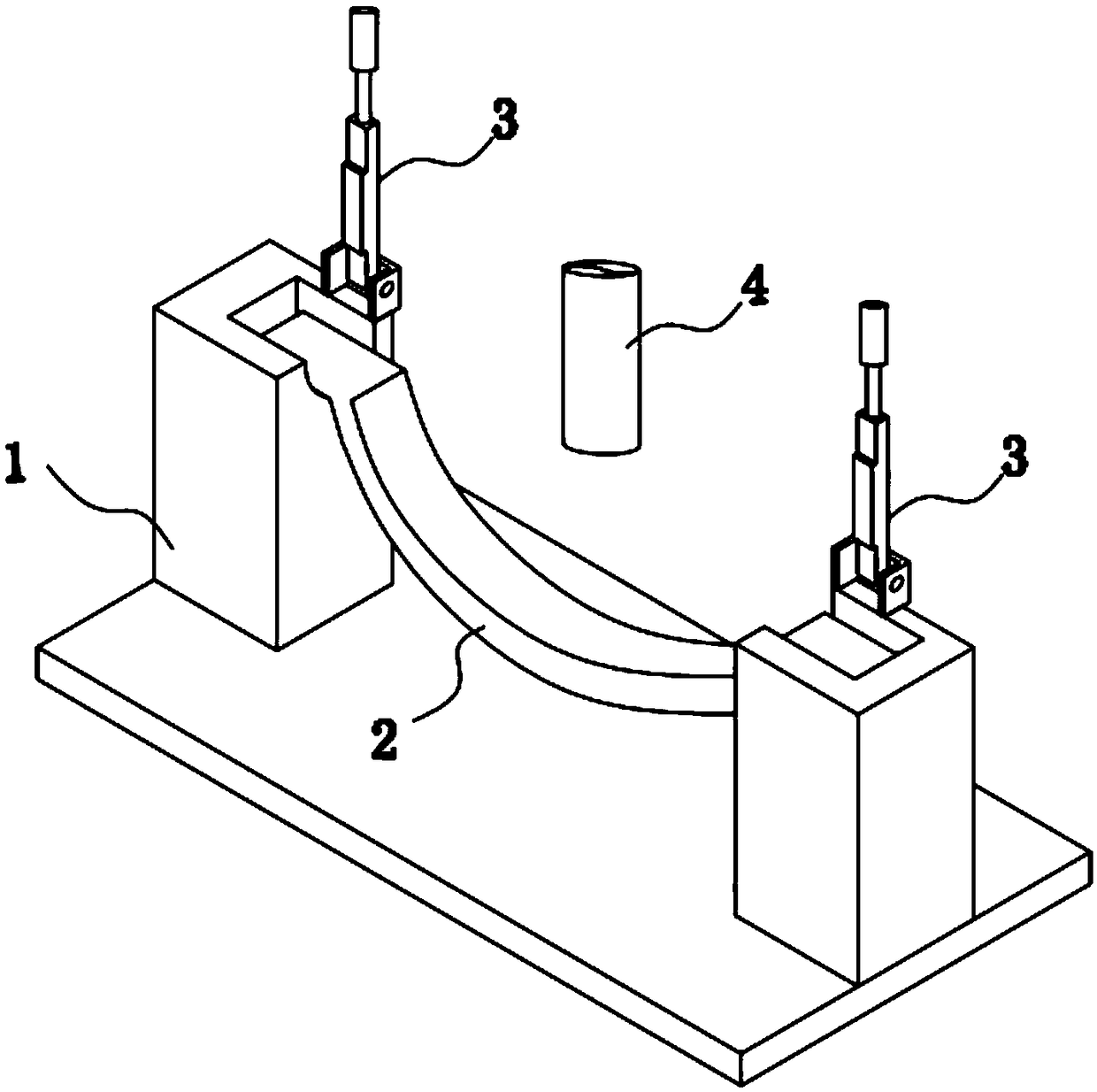

[0025] The present invention provides such Figure 1-3 A method for detecting the bending mechanical properties of a sample, comprising the steps of:

[0026] S1: Select several groups of samples and label them as A1 to An respectively;

[0027] S2: Place the sample labeled A1 on the support, and use clamps to fix both ends of the sample A1 on the support;

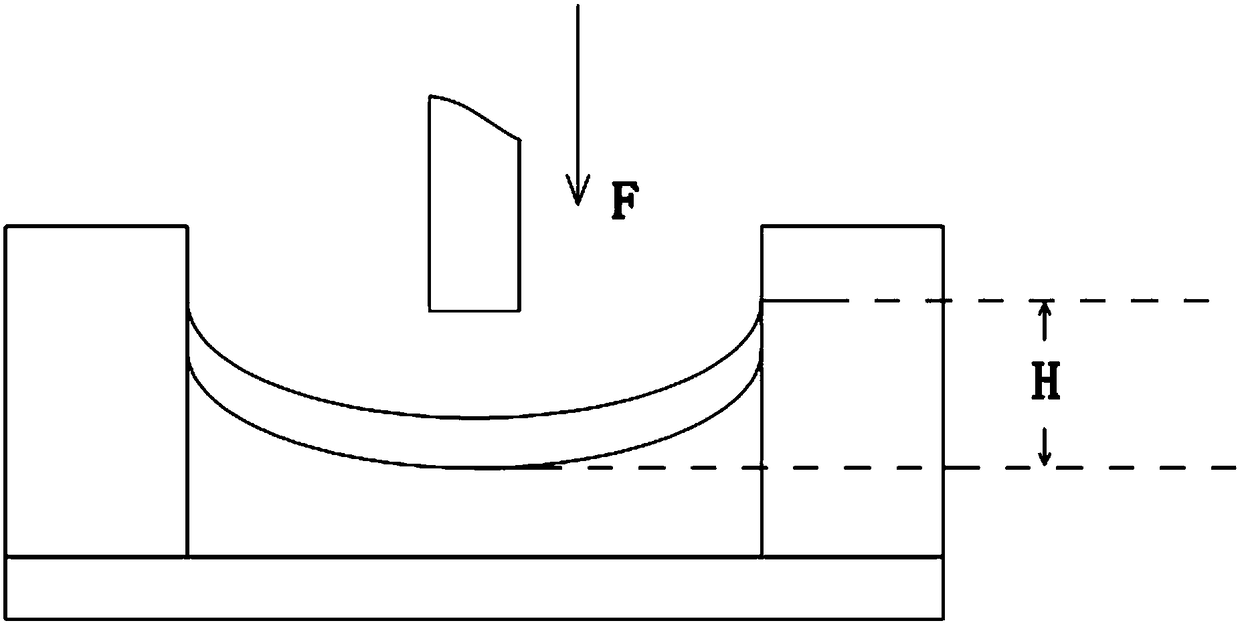

[0028] S3: Use the piston rod of the hydraulic cylinder to pressurize the sample A1, record the length H1 from the top of the curved arc of the sample A1 to the horizontal position at both ends, and record the pressure F1 of the hydraulic cylinder at this time;

[0029] S4: Then repeat the above-mentioned steps S1-S3 until all the tests on samples A1 to An are completed, and two sets of data H1 to Hn and F1 to Fn are obtained;

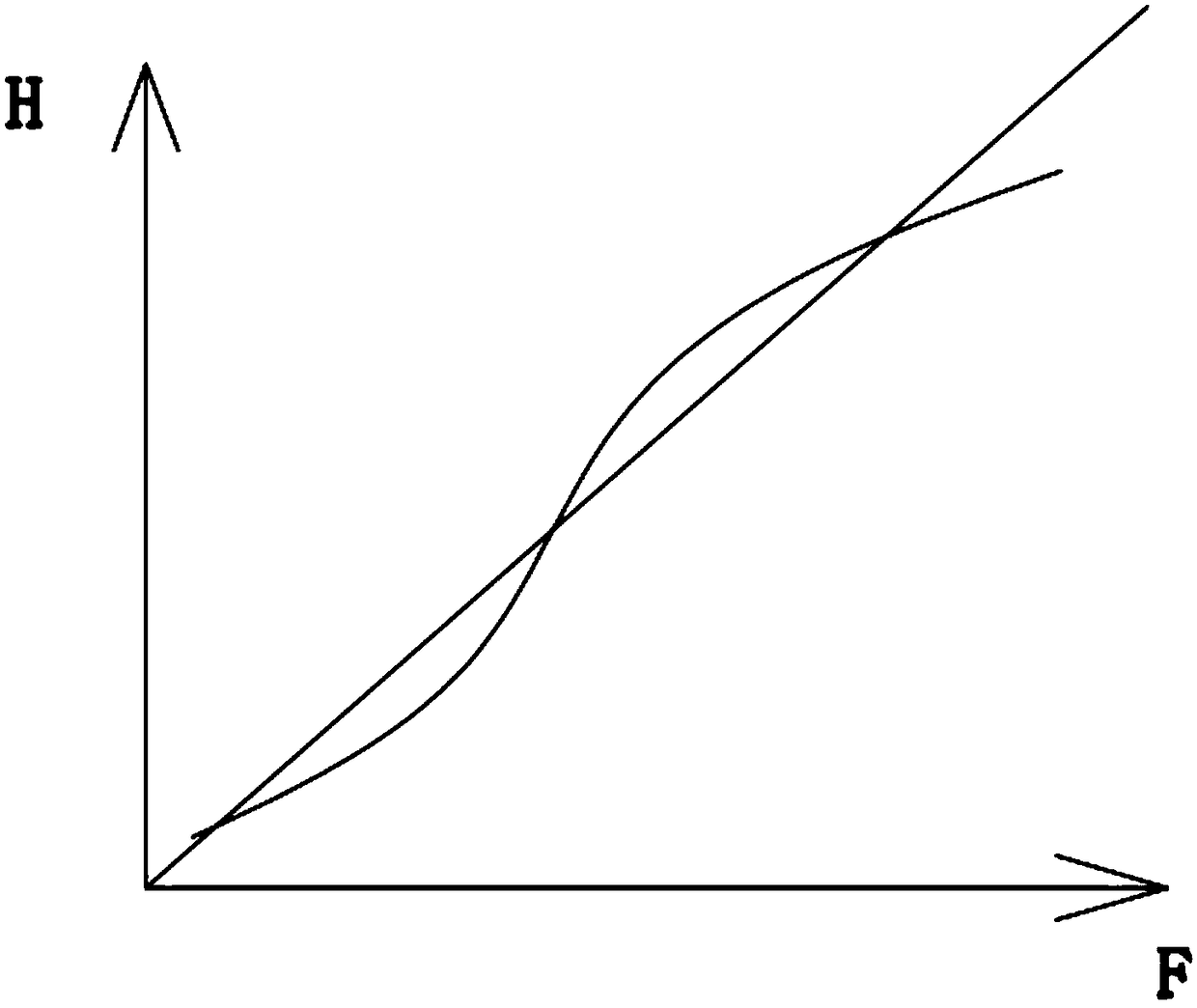

[0030] S5: In the plane rectangular coordinate system, take the pressure F as the abscissa and the length H as the vertical coordinate to make a plane rectangular coordinate diagram, and then dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com