Method for setting up secondary lining concrete crushing strength curve after tunnel fire

A compressive strength, secondary lining technology, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, and test material hardness, etc., can solve problems such as judgment of unsuitable concrete compressive strength, and achieve damage level Reasonable judgment and the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, implementation examples and specific experimental data.

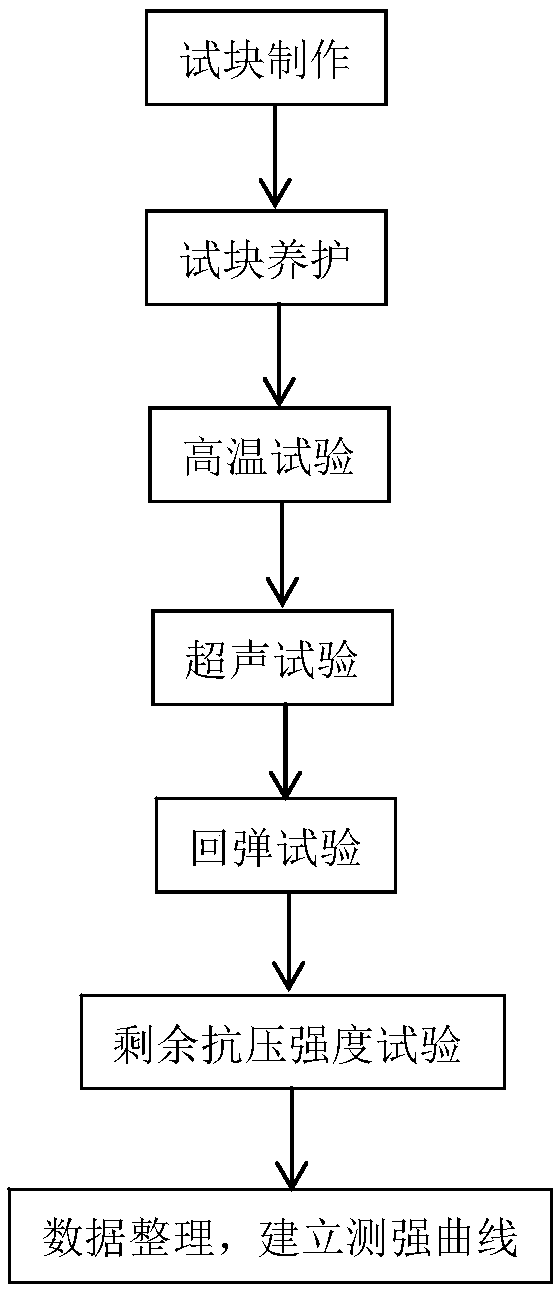

[0025] like figure 1 As shown, the present invention establishes the compressive strength curve of the secondary lining concrete after fire through test block production, test block maintenance, high temperature test, ultrasonic test, rebound test, pressure test and test data analysis. Specific steps are as follows:

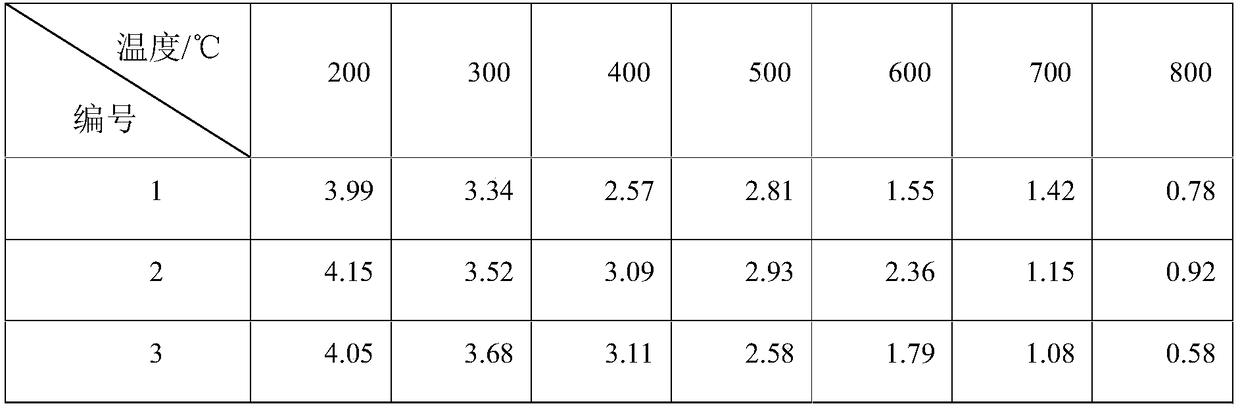

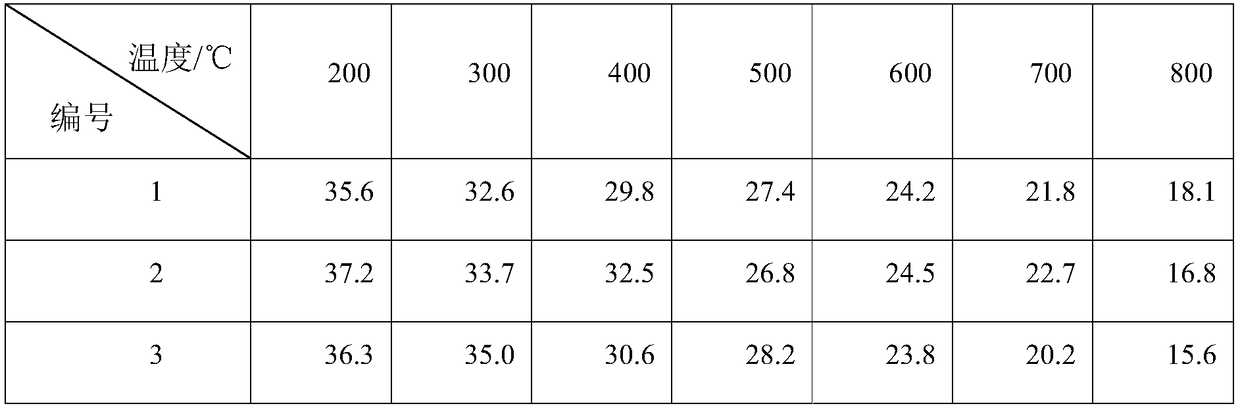

[0026] The first step, test block production: use ordinary Portland cement with 32.5 strength grade, crushed stone coarse aggregate with an average particle size of 30mm, yellow sand (coarse sand) fine aggregate, and tap water as raw materials, according to 1:0.45:1.36 : The mix ratio design of 3.03 is in line with the c30 test block of the concrete strength level of the secondary lining of the tunnel. The same temperature level includes 6 standard test blocks of 150mm*150mm*150mm and 2 n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com