Test method for interface bonding strength between rubber and composite material

A composite material and interface bonding technology, which is applied in the field of testing, can solve problems such as not reflecting the interface bonding strength between rubber materials and composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

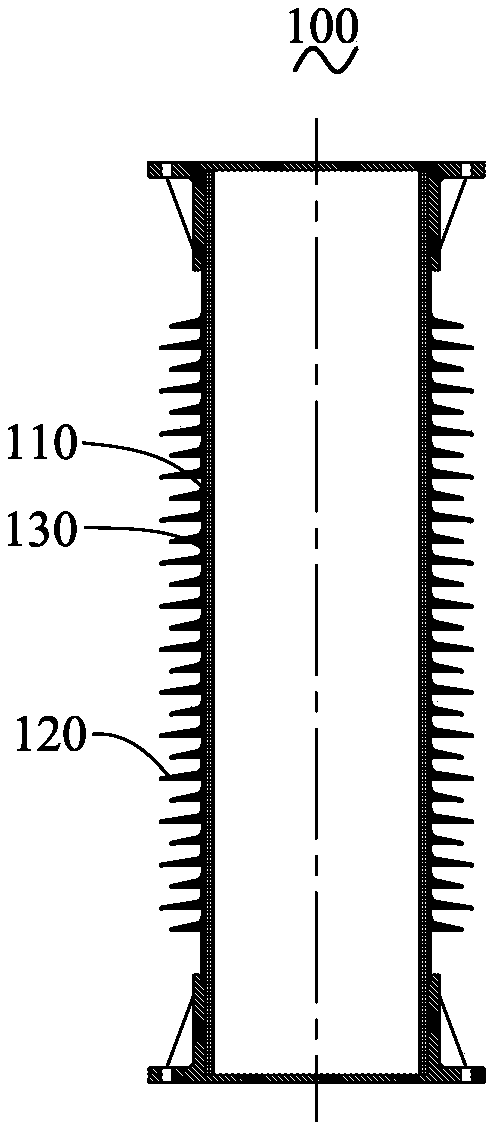

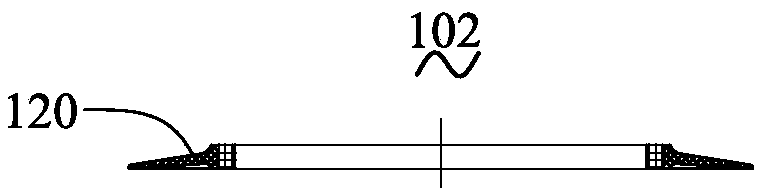

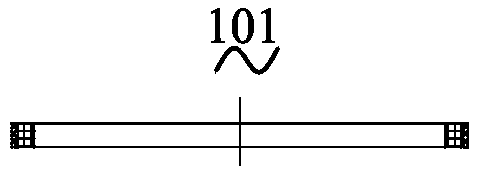

[0058] A method for testing the bonding interface strength of rubber and composite materials, combining Figure 1-6 , including the following steps:

[0059] S1. Make test sample blocks, specifically including:

[0060] S01: Production of composite insulation products:

[0061] see figure 1 , the composite insulation product is a composite insulator 100, including a hollow insulating tube 110 and a silicone rubber shed 120 coated on the insulating tube, including the following specific steps:

[0062] S001. Prepare an insulating tube 110. The insulating tube 110 is formed by impregnating glass fiber yarn with epoxy resin glue solution through a winding and curing process. The curing agent is methyl tetrahydrophthalic anhydride curing agent.

[0063] S002. Uniformly coat a layer of vinyl tris(2-methoxyethoxy)silane coupling agent on the outside of the insulating tube 110 .

[0064] S003. Inject high-temperature vulcanized silicone rubber on the outer surface of the insulati...

Embodiment 2

[0077] This embodiment is basically the same as embodiment one, except that the rubber sample block width W2=10mm ± 0.5, all the other are the same as embodiment one, a test sample block-sample four is processed and tested and the test data is recorded as Table 2 shows.

[0078] Table 2 Test data records

[0079]

[0080] In this example, the width of the rubber sample block was changed for testing. Compared with the data in Table 1 in Example 1, the measured bonding strength σ under different sizes max The values are still similar, which further illustrates the stability of the test method.

Embodiment 3

[0082] This embodiment is basically the same as embodiment two, the difference is that gamma-glycidoxypropyltrimethoxysilane coupling agent is used in this embodiment, and the rest are the same as embodiment two, and a test sample piece is processed - Sample five was tested and the test data was recorded as shown in Table 3.

[0083] Table 3 Test data records

[0084]

[0085] In this embodiment, the components of the coupling agent are changed, compared with the data in Table 2 in Example two, it can be known that the adhesive strength of the vinyl tris (2-methoxyethoxy) silane coupling agent is used It is greater than the bonding strength of γ-glycidoxypropyltrimethoxysilane. Through this test, the bonding strength of the interface between the rubber material and the composite material can be effectively characterized, and it is helpful to select a better bonding strength during the production process. Processes and materials to improve the interface bonding performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com