A method for detecting internal defects of cemented carbide rolls

A cemented carbide and detection method technology, which is applied to measuring devices, instruments, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as unrepaired cracks, increased rolling costs, and inability to continue to use, so as to ensure quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The invention provides a method for detecting internal defects of a cemented carbide roll, comprising the following steps:

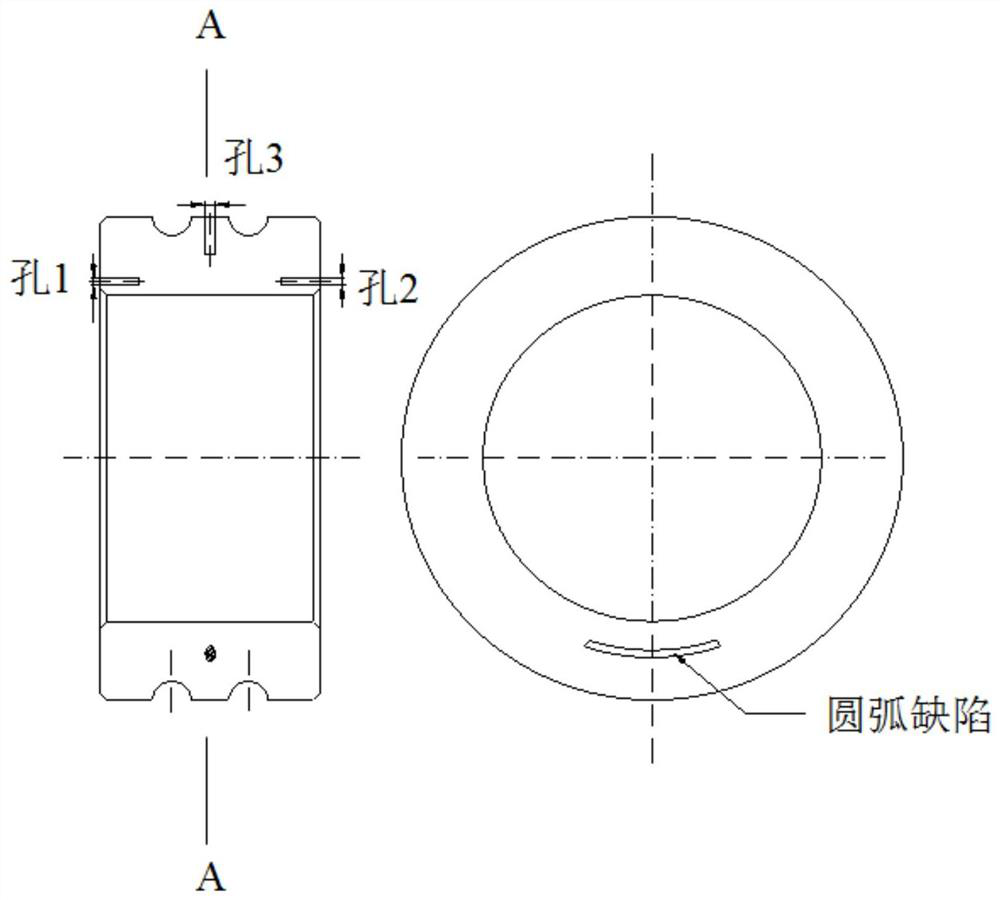

[0041] (1) Taking the arc surface of the slotted roll as the testing surface, select 12 pieces of slotted rolls as testing samples, numbered 1 to 12, and make a comparison test block to ensure that the curvature of the comparison test block and the test sample are the same, specifically as follows figure 1 As shown, the phased array ultrasonic detector adopts omniscan MX2, uses a 16-chip probe with a frequency of 10MHz, and is equipped with a curved wedge that is the same or close to the internal curvature of the product to be tested, which facilitates good contact between the probe and the sample to be tested, and makes the ultrasonic Energy is more easily transferred to the interior of the sample;

[0042] (2) Set a section of iron wire arc with a length of 20-30mm inside the comparison test block, and use the method of spark punching to punch t...

Embodiment 2

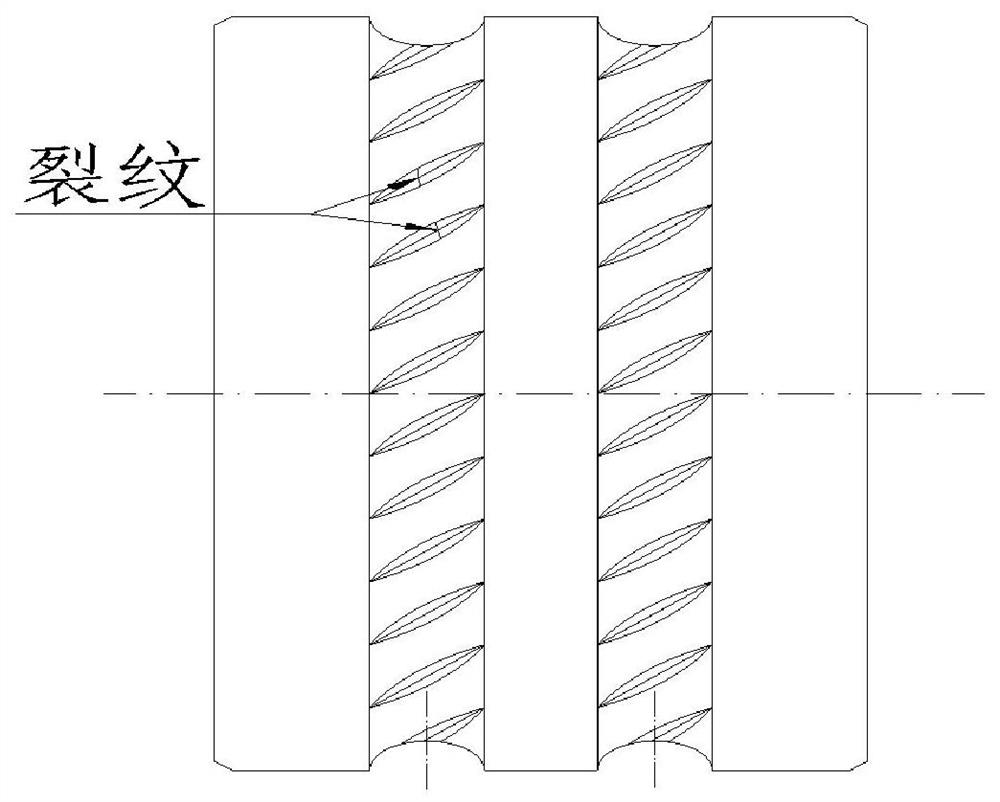

[0048] The present invention provides a method for detecting internal defects of cemented carbide rolls. To detect cracks in grooves of ribbed rolls, 12 pieces of ribbed rolls are selected as test samples, numbered 13-24, using the same sensitivity and scanning as in Example 1. The detection method is carried out, and the detection results are shown in Table 2:

[0049] Table 2 Test results

[0050]

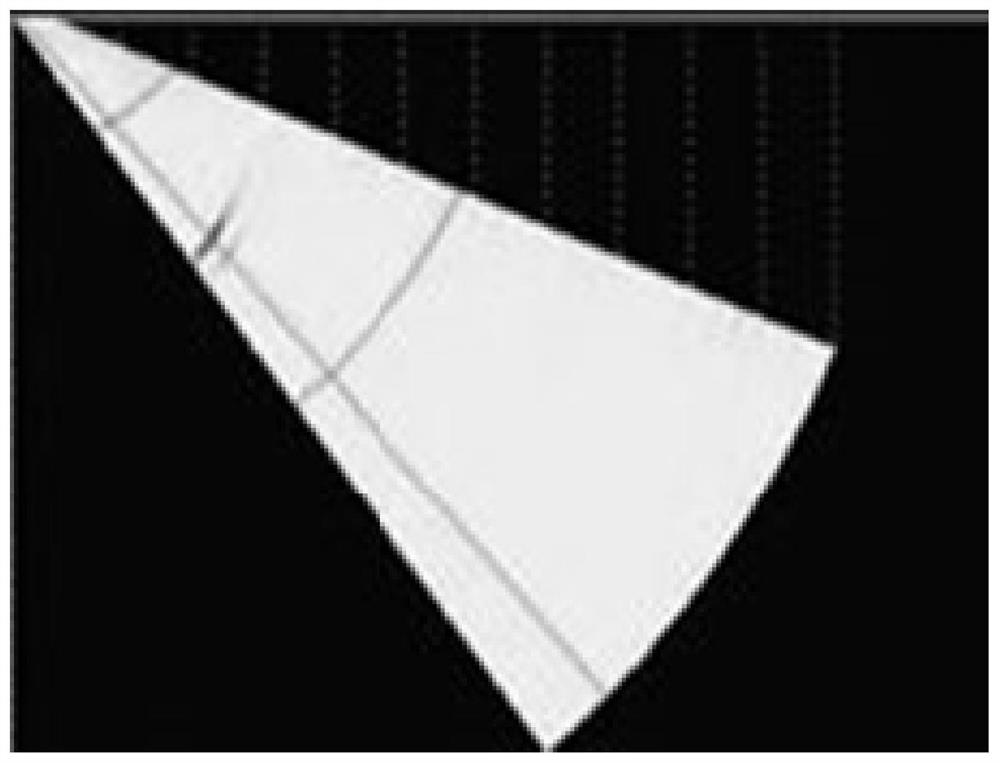

[0051] Image 6 It is the defect waveform diagram of No. 15 ribbed roll (158 / 87-62-¢10 screw). According to the waveform diagram, it can be concluded that the fatigue crack in the groove is 10mm deep, 12mm long, and 8mm after grinding. There are still fatigue cracks after grinding. , Figure 7 It is the defect waveform diagram of cracks still remaining after grinding of No. 15 ribbed roll, Figure 8 It is the physical picture of No. 15 ribbed roll after grinding.

Embodiment 3

[0053] The present invention provides a method for detecting internal defects of cemented carbide rolls. To detect cracks in the ribs of ribbed rolls, 12 pieces of ribbed rolls in Example 2 are used as test samples, numbered 25-36, and the same method as in Example 2 is used. The sensitivity and scanning method are used to detect ribbed rolls, and the test results are shown in Table 3:

[0054] Table 3 Test results

[0055]

[0056] Figure 9 It is the defect waveform diagram of No. 34 engraved ribbed roll (360 / 240-105-¢8 screw). According to the waveform diagram, it can be concluded that the crack in the rib is 34mm deep and 5mm long. It is unnecessary to regrind and it will be rejected directly. Figure 10 It is the physical picture of the crack inside the rib of No. 34 ribbed roll.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com