A non-destructive testing method for small-diameter pipes based on the principle of electromagnetic ultrasonic phased array focusing

An electromagnetic ultrasonic and non-destructive testing technology, which is used in the analysis of solids using sonic/ultrasonic/infrasonic waves to improve detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

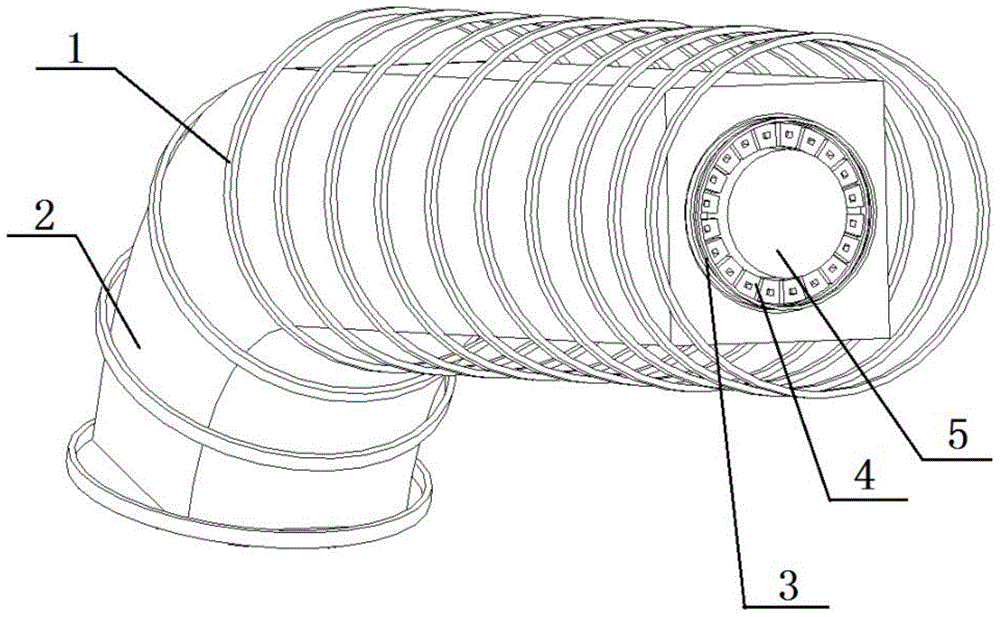

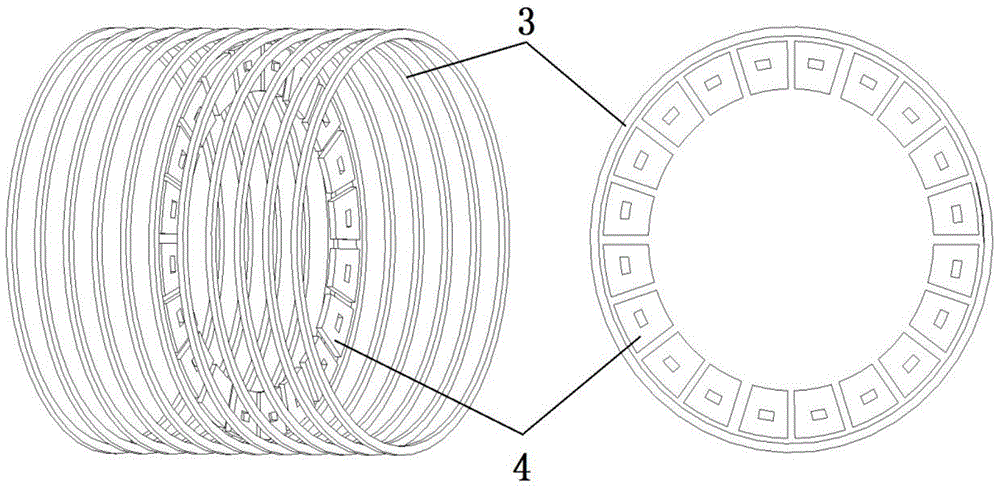

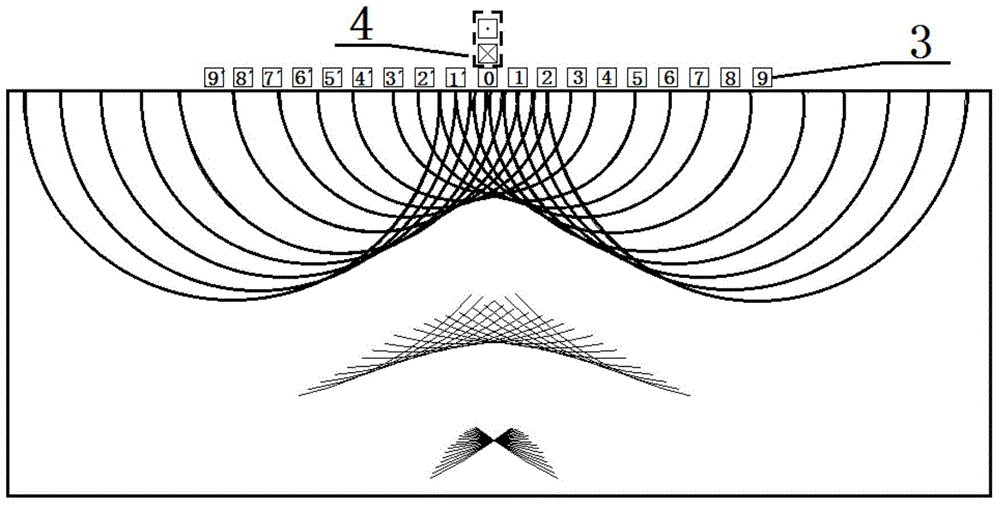

[0025] The rapid detection principle of the method of the present invention is as follows: a solenoid electromagnet unit placed outside the small-diameter tube and coaxial with it to generate a strong bias magnetic field is arranged coaxially in the small-diameter tube to generate ultrasonic body waves. The electromagnetic ultrasonic probe is composed of the electromagnetic ultrasonic excitation unit of the coil and the array detection coil unit uniformly arranged along the pipe circumference to detect the ultrasonic signal; Set the magnetic field; then set the excitation time of each excitation coil of the electromagnetic ultrasonic excitation coil unit according to the focusing law, and use the electromagnetic ultrasonic device to sequentially excite each coil to generate ultrasonic waves, thereby realizing the focusing of the ultrasonic beam in the area to be detected; The array detection coil unit arranged circumferentially on the cross-section detects the voltage signal ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com