Optical imaging mechanism with automatic zooming and anti-shake functions

An automatic zoom and optical imaging technology, applied in optics, optical components, cameras, etc., can solve the problems of high cost, large volume, and low imaging quality, and achieve the effect of improving imaging quality and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the technical scheme of the present invention more intuitively and completely, the non-limiting feature descriptions are as follows in conjunction with the accompanying drawings of the present invention:

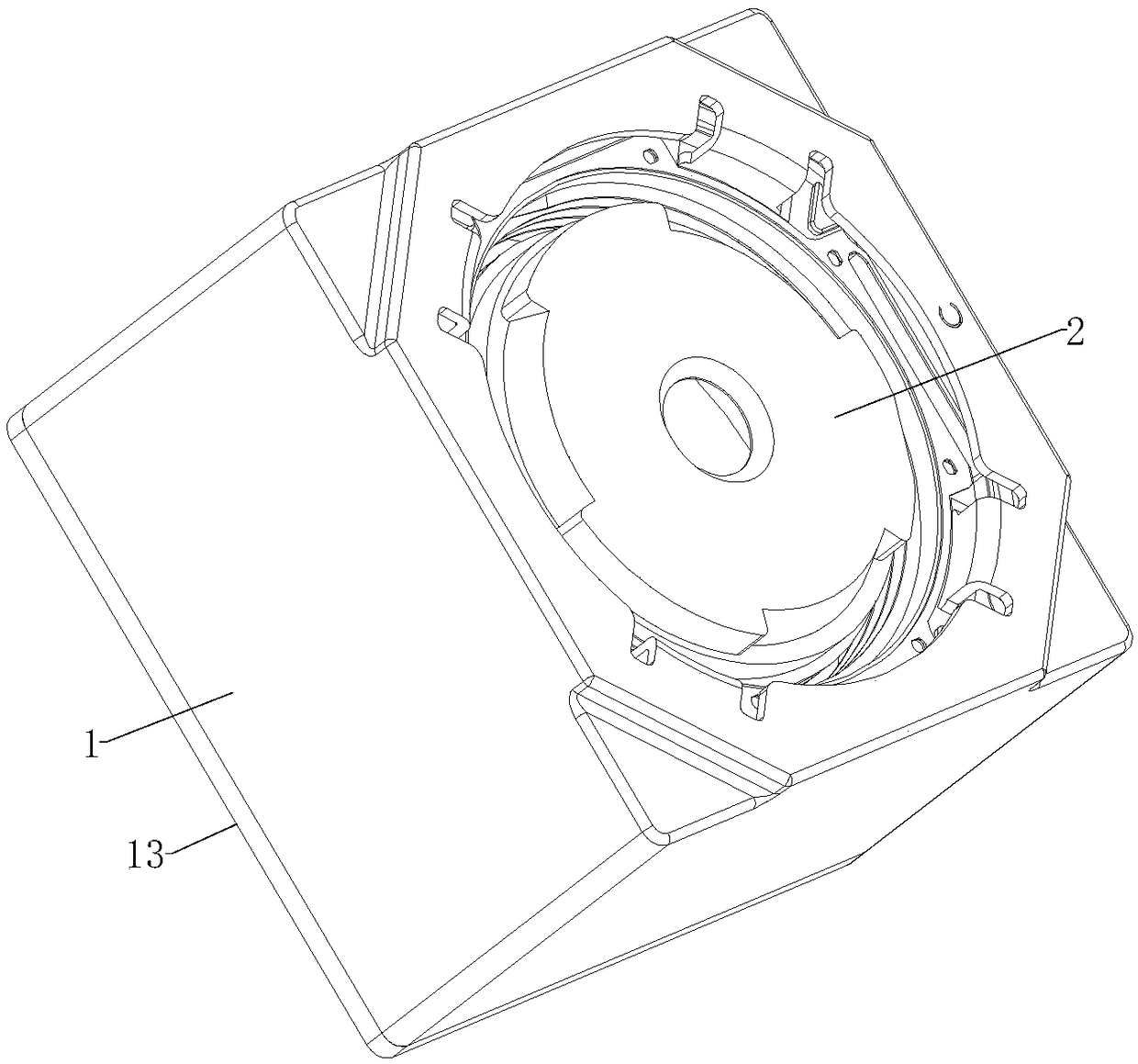

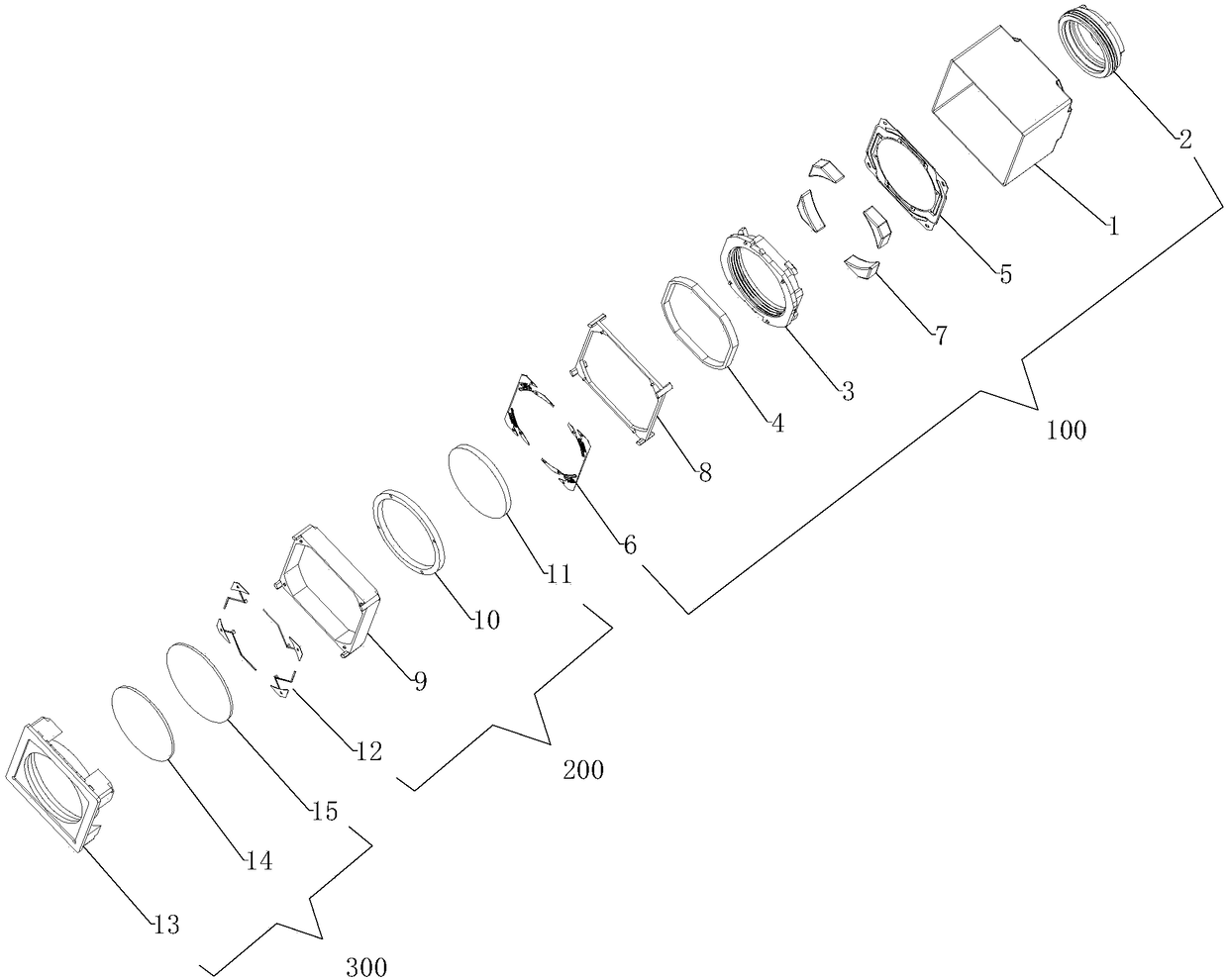

[0024] Such as figure 1 — Image 6 As shown, an optical imaging mechanism with automatic zoom and anti-shake function, which includes a first optical assembly 100, a second optical assembly 200 and a third optical assembly 300 connected in sequence;

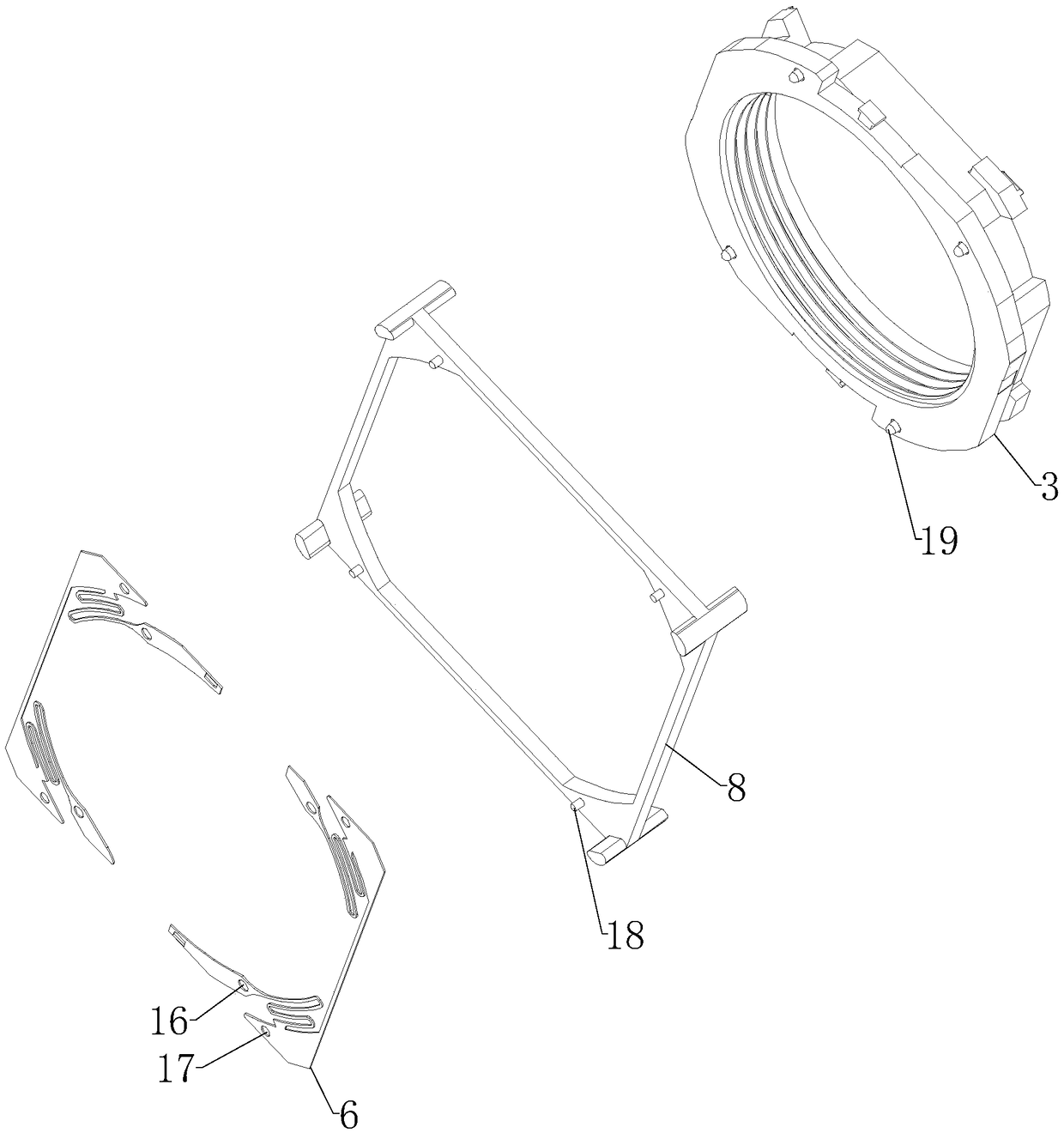

[0025] The first optical assembly 100 includes a yoke ring 1, a first optical lens 2 arranged in the yoke ring 1, a carrier 3 arranged in the yoke ring 1, a coil 4 arranged outside the carrier 3, and a coil 4 arranged in front of and behind the carrier 3. The front reed 5 at both ends, the rear reed 6 and the magnets 7 arranged at the four corners of the front reed 5, the front reed 5 is fixed in the yoke ring 1, the magnet 7 is located outside the coil 4, and the rear reed 6 is connected with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com