Industrial control system

An industrial control system, industrial control host technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve problems such as on-site space limitations, equipment control system problems, inability to operate data business layers, etc., to reduce the number of on-site Space requirements, the effect of improving stability and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

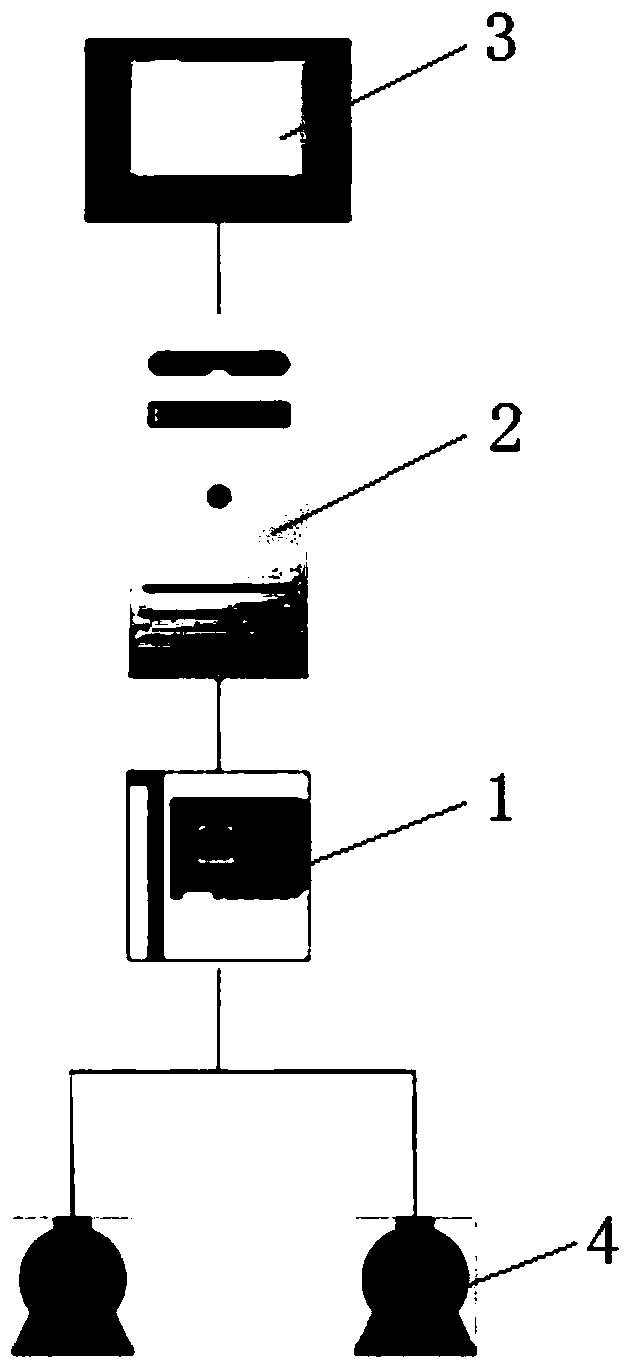

[0017] Such as image 3 As shown, this embodiment provides an industrial control system, including a PCI interface motion control card 1 for controlling electromechanical equipment, the PCI interface motion control card 1 is inserted into the PCI socket of the industrial control host 2, and the industrial control host 2 communicate with the HMI man-machine interface 3 .

[0018] In this embodiment, the industrial control host 2 communicates with the HMI man-machine interface 3 using the Modbus protocol based on TCP / IP or serial port or 485 interface.

[0019] In this embodiment, the HMI man-machine interface 3 communicates with the industrial control host 2 through a PVI cable.

[0020] In this ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap