A novel energy-saving and environment-friendly electric wire

An energy saving, environmental protection, wire technology, applied in the field of wire, can solve the problems of reducing the service life of the wire, accelerating insulation aging, and increasing the temperature of the conductor surface, achieving the effect of obvious contrast, reducing heat loss, and improving heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

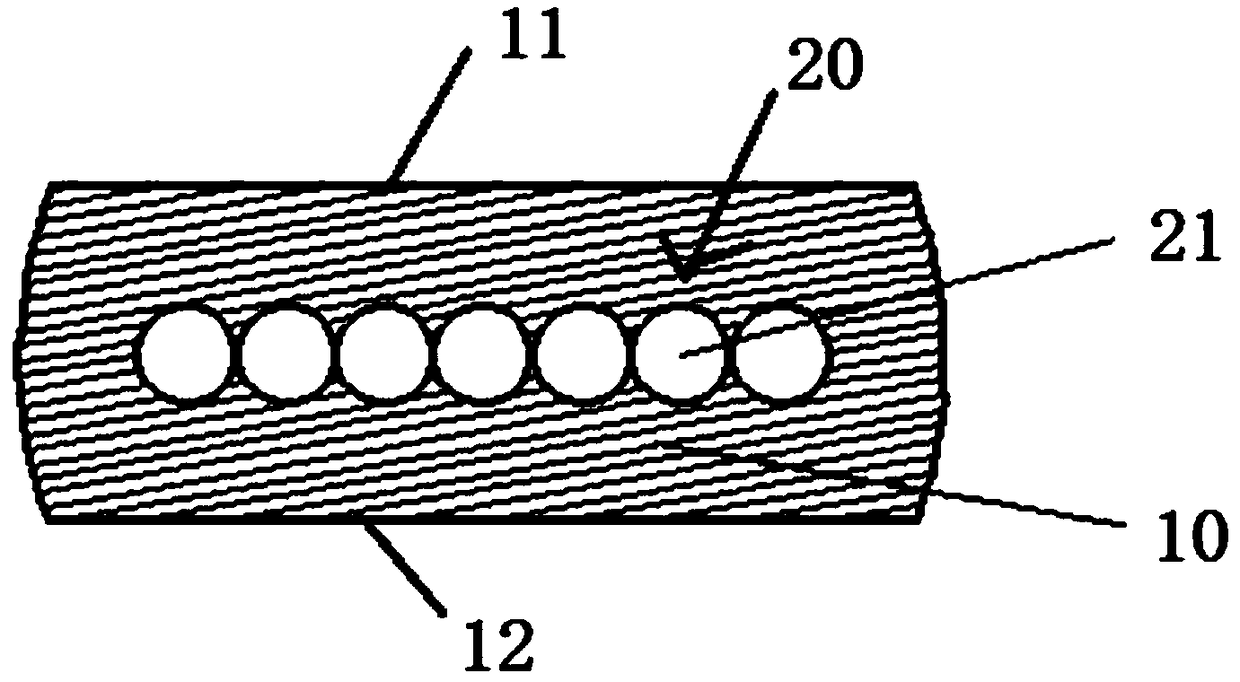

[0017] A new type of energy-saving and environment-friendly electric wire, comprising an insulating sheath layer 10 and a conductor core group 20 arranged in the insulating sheath layer 10, the insulating sheath layer 10 is a flat sheath layer, and the upper and lower flat surfaces 11, 12 are connected to each other Parallel, it is convenient for the wires to be attached to the working surface, making the wiring structure of the wires more compact. The wire of this embodiment is 10mm 2 And the following electric wires, the conductor core group 20 includes a row of conductor cores, and a row of conductor cores includes seven conductor monomers 21 arranged side by side along the width direction of the flat sheath layer. The ratio of the width to the height of the insulating sheath layer 10 is 3:1. The conductor monomers 21 adopt a parallel arrangement structure, and the insulation extrusion process can be carried out directly after the conductors are drawn, which reduces the co...

Embodiment 2

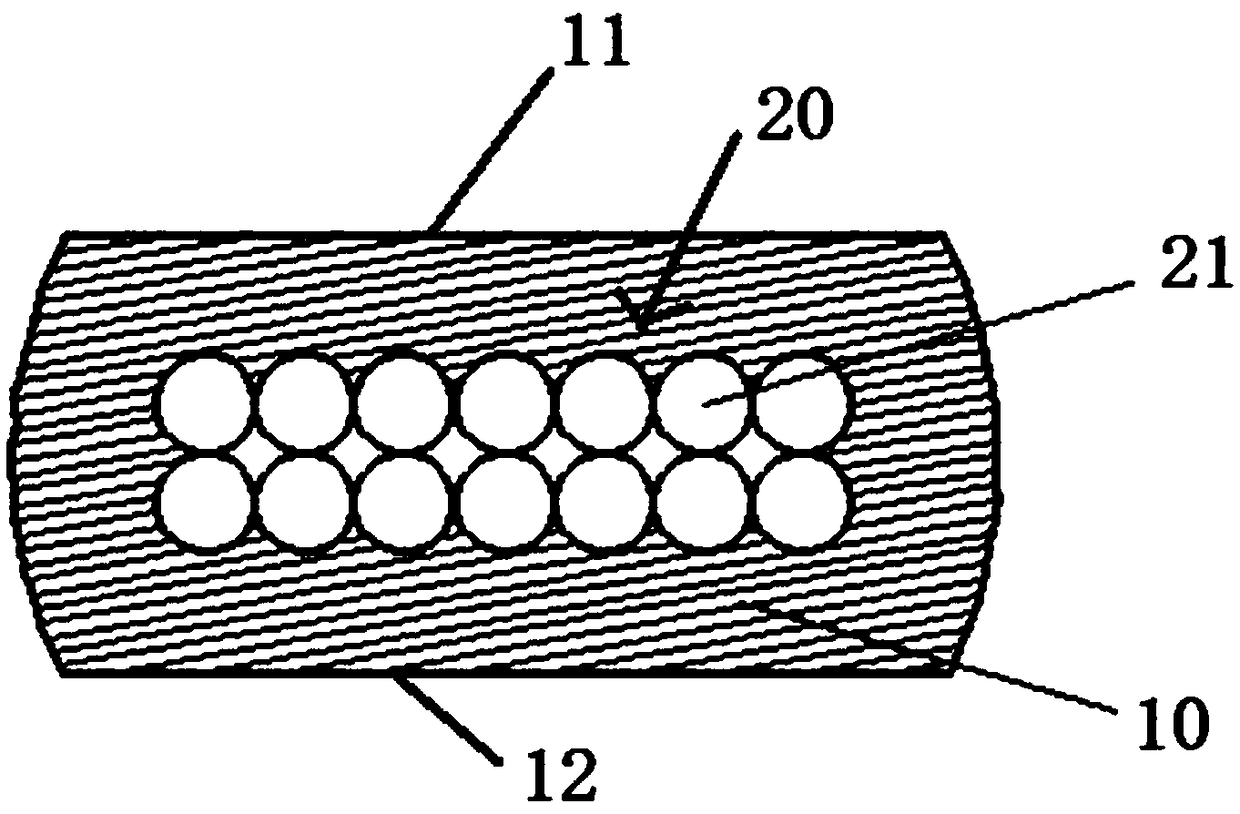

[0020] A new type of energy-saving and environment-friendly electric wire, comprising an insulating sheath layer 10 and a conductor core group 20 arranged in the insulating sheath layer 10, the insulating sheath layer 10 is a flat sheath layer, and the upper and lower flat surfaces 11, 12 are connected to each other Parallel, it is convenient for the wires to be attached to the working surface, making the wiring structure of the wires more compact. The electric wire of this embodiment is 16-50mm 2 The electric wire, the conductor core group 20 includes two rows of conductor cores, the two rows of conductor cores are arranged in a stacked manner, and each row of conductor cores includes seven conductor monomers 21 arranged side by side along the width direction of the flat sheath layer. The ratio of width to height of the insulating sheath layer 10 is 2.7:1. The conductor monomers 21 adopt a parallel arrangement structure, and the insulation extrusion process can be carried ou...

Embodiment 3

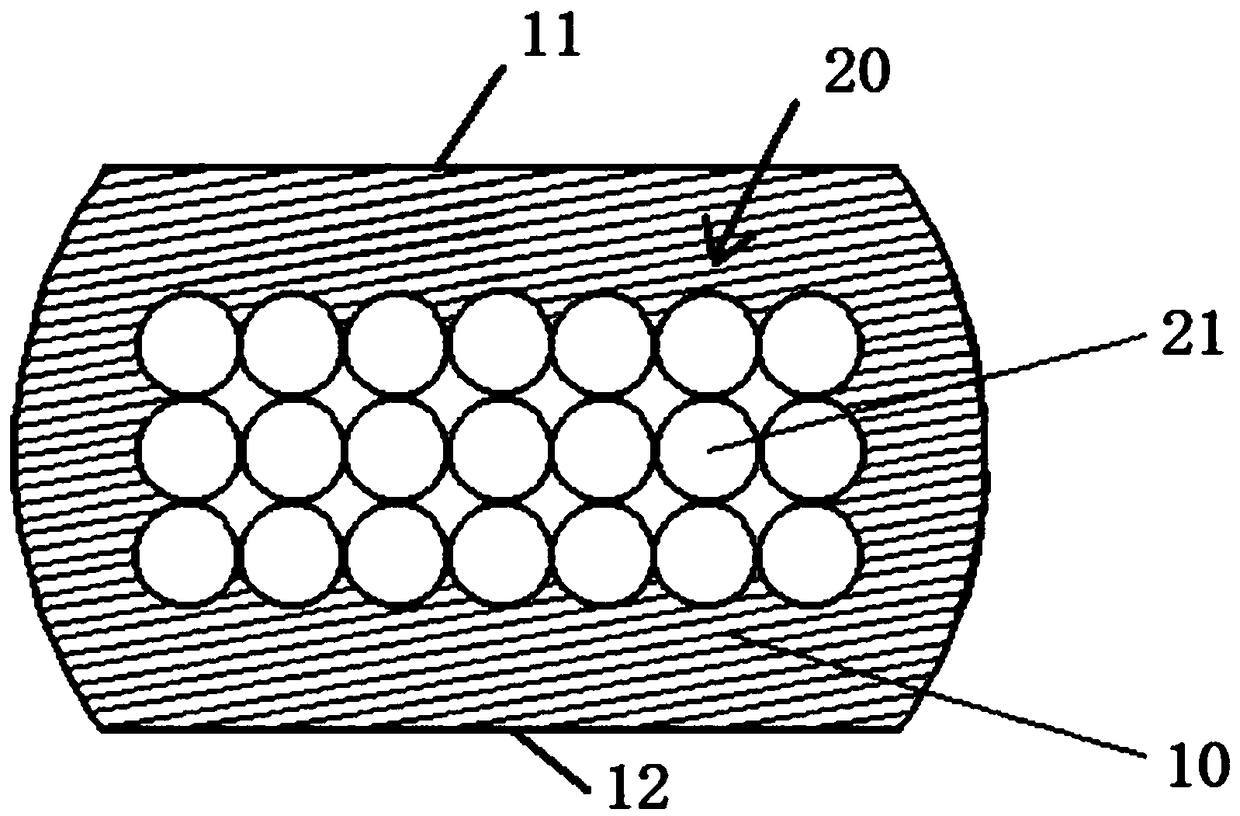

[0023] A new type of energy-saving and environment-friendly electric wire, comprising an insulating sheath layer 10 and a conductor core group 20 arranged in the insulating sheath layer 10, the insulating sheath layer 10 is a flat sheath layer, and the upper and lower flat surfaces 11, 12 are connected to each other Parallel, it is convenient for the wires to be attached to the working surface, making the wiring structure of the wires more compact. The electric wire of this embodiment is 70-120mm 2 For electric wires, the conductor core set 20 includes three rows of conductor cores, the three rows of conductor cores are arranged in a stacked manner, and each row of conductor cores includes seven conductor monomers 21 arranged side by side along the width direction of the flat sheath layer. The ratio of width to height of the insulating sheath layer 10 is 2.5:1. The conductor monomers 21 adopt a parallel arrangement structure, and the insulation extrusion process can be carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com