Flat wire motor stator slot insulation structure, and processing equipment and processing technology thereof

A technology for motor stator and processing equipment, applied in the shape/style/structure of winding insulation, winding insulation material, laying solid insulation, etc., can solve the problems of stator slot insulation failure, unstable structure and insulation performance, etc. High reliability, stable insulating layer structure, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The concrete implementation method of the present invention is as follows:

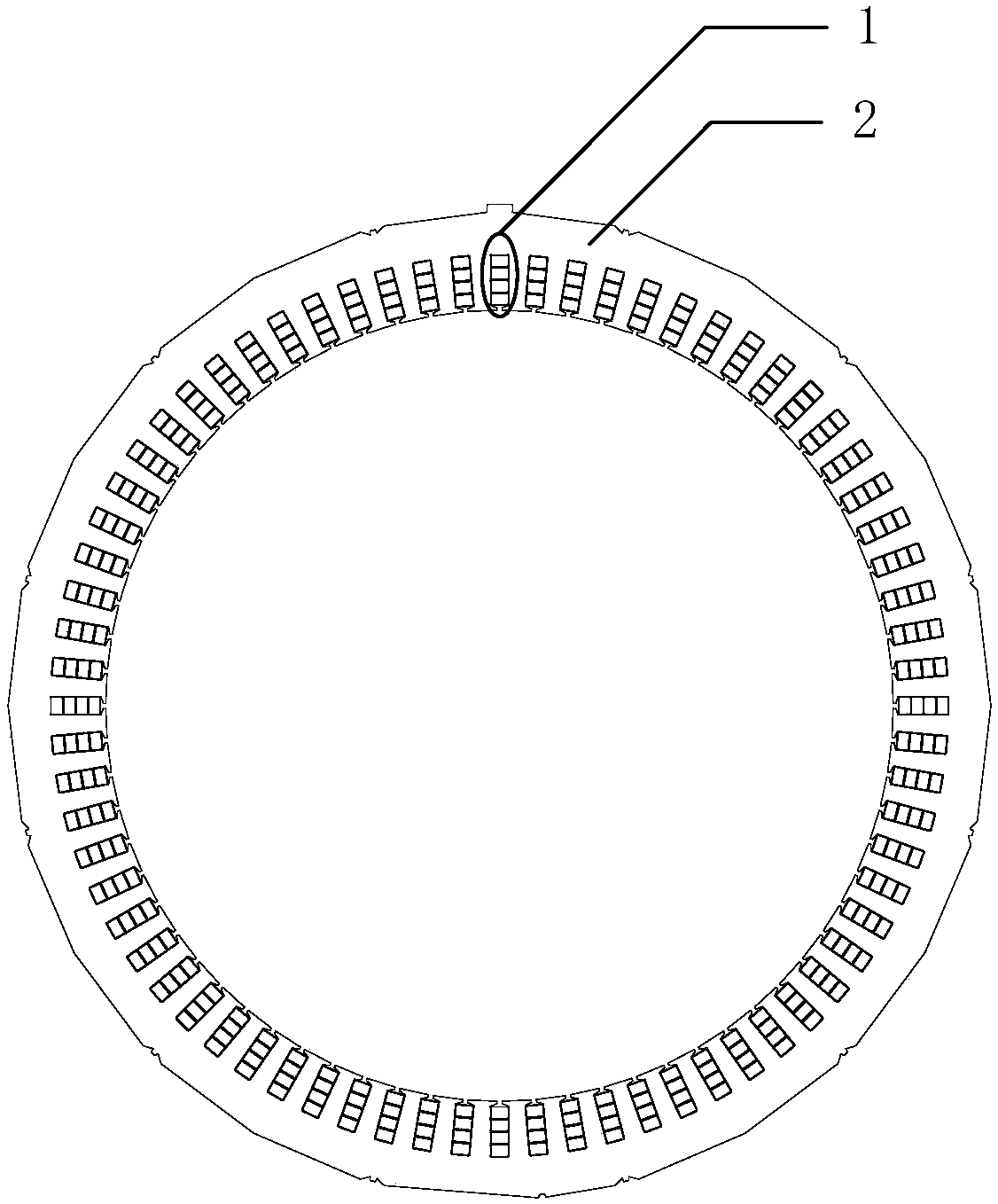

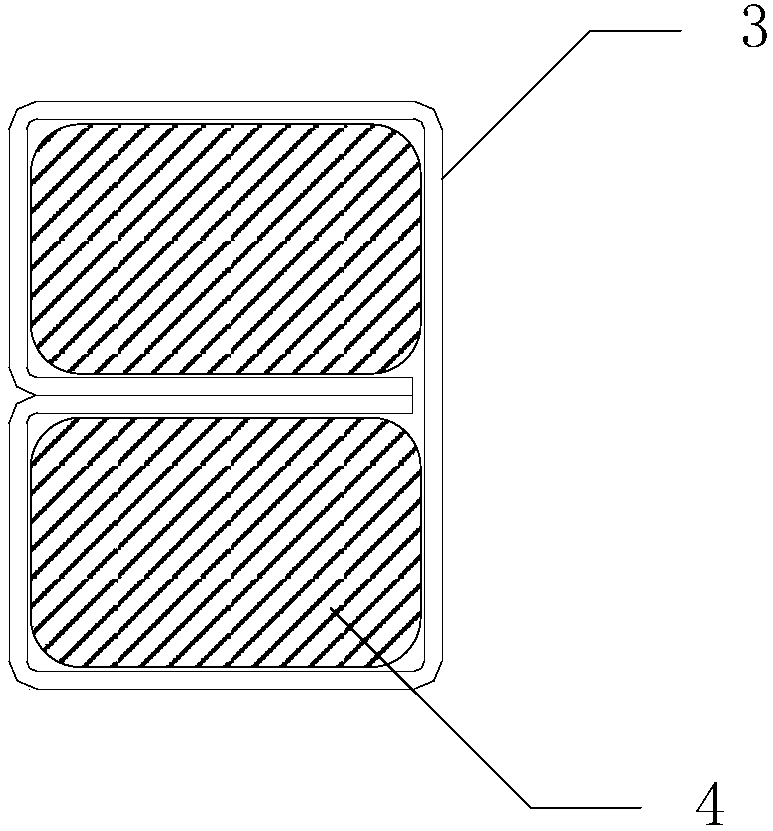

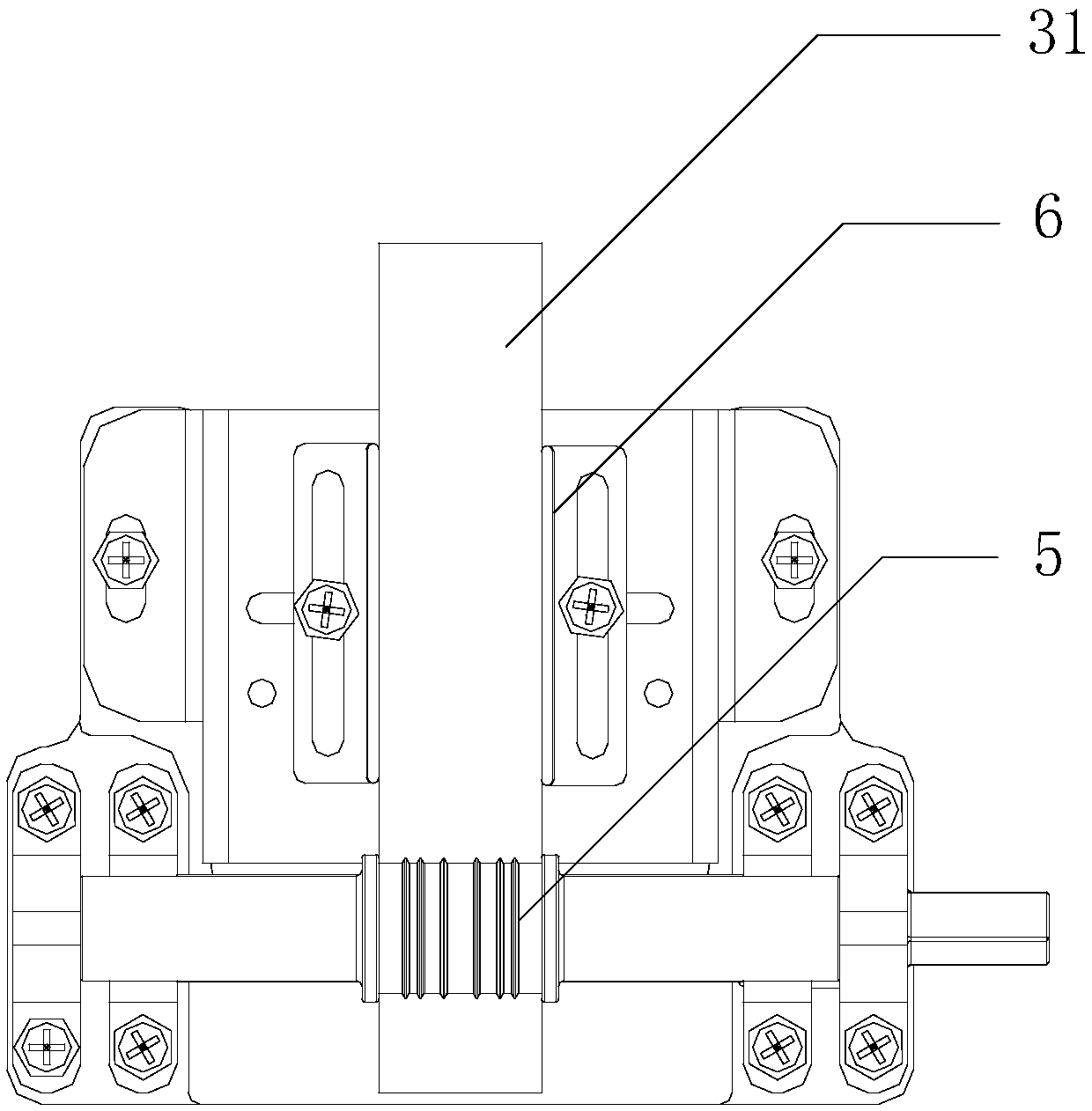

[0024] figure 1 It is a schematic diagram of a flat wire motor stator, where 1 is the stator slot of the flat wire motor, and 2 is the stator core of the flat wire motor; figure 2 It is a schematic diagram of the insulation layer of flat wire motor, in which 3 is insulating paper, and 4 is flat wire conductor. A certain number of stator slots 1 are opened on the stator core 2 of the flat wire motor, and a plurality of flat wire conductors 4 are arranged in the stator slots 1. Electrical insulation is required, so an insulating layer 3 is provided between the flat wire conductor 4 and the stator slot 1 to achieve the effect of electrical isolation.

[0025] The insulating layer 3 is made of paper insulating material. The insulating paper has good insulating properties and mechanical strength. In the present invention, the insulating layer is processed into a cuboid structure to facilitate coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com