A contact cooling motor

A contact type, motor housing technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of dust entry, poor heat radiation effect, poor motor ventilation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

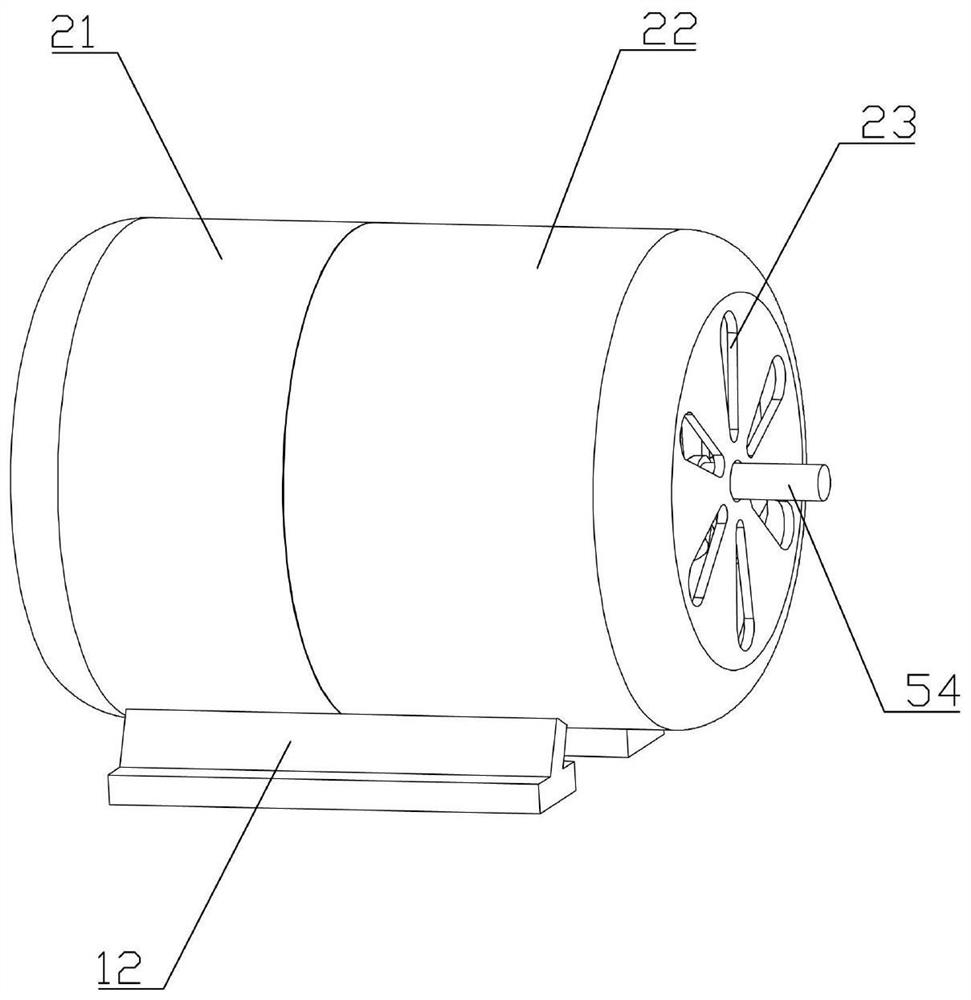

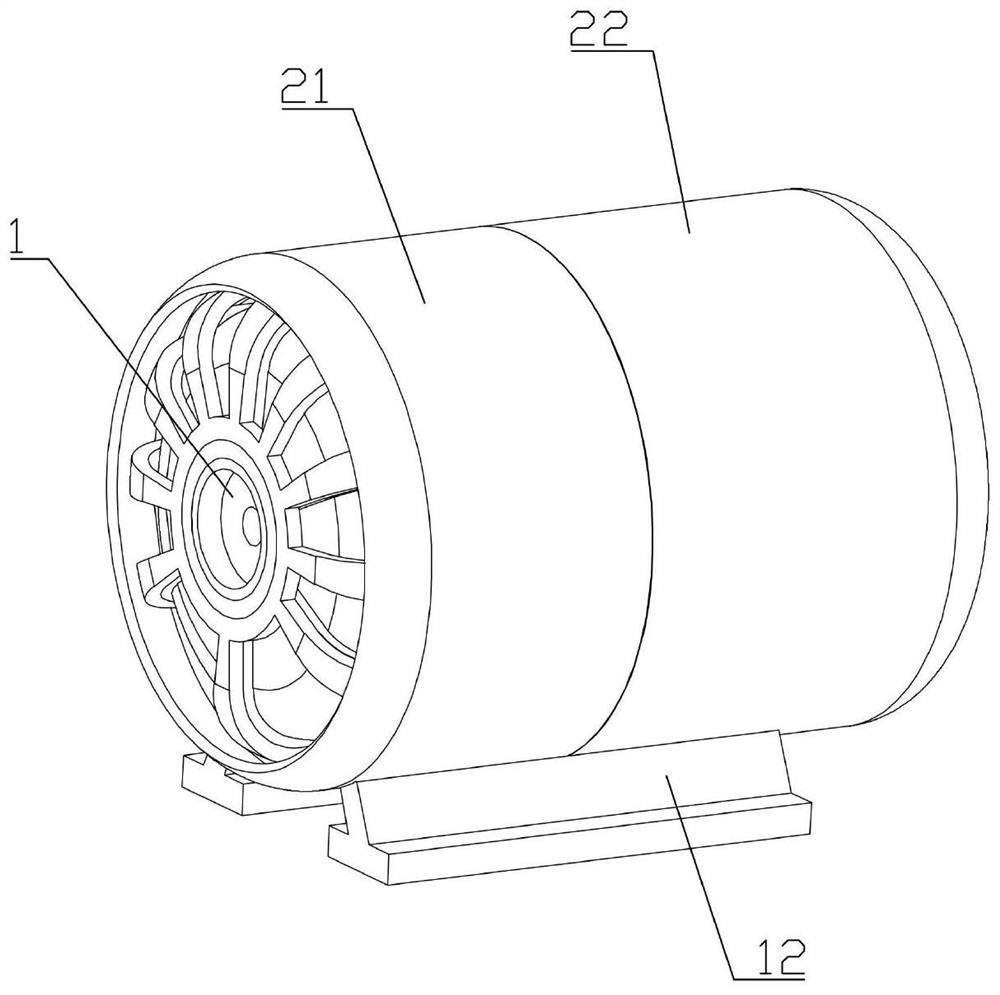

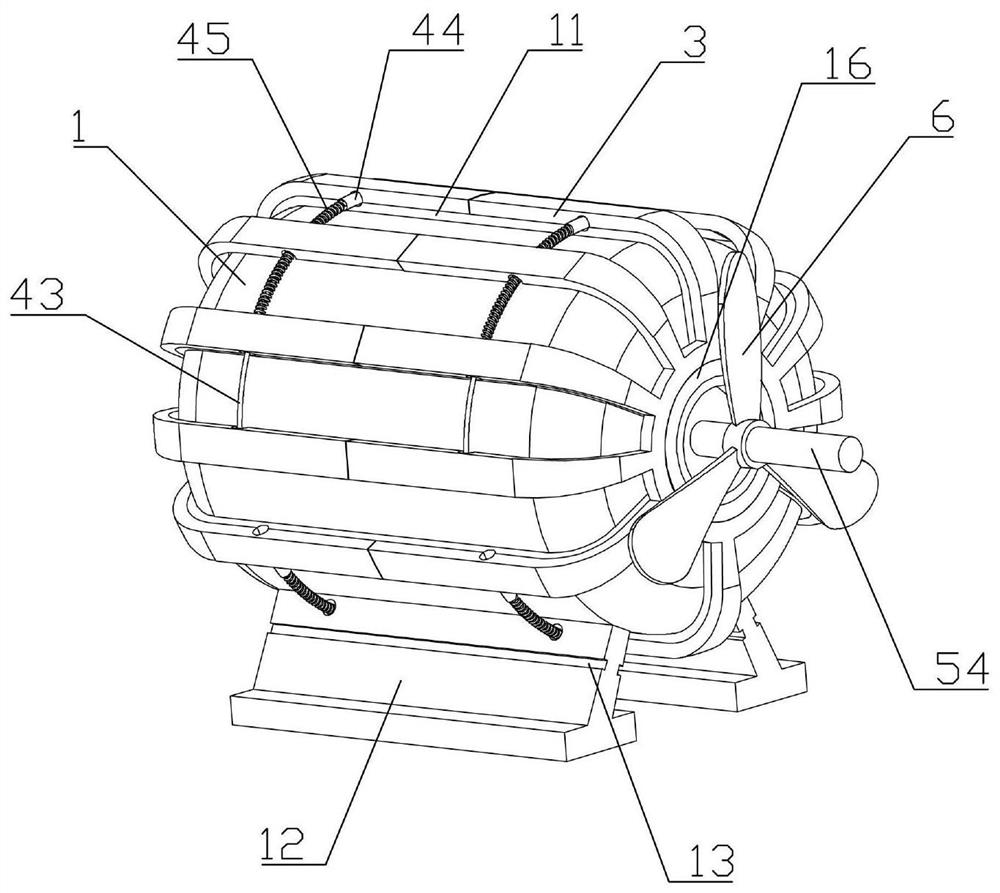

[0030] Such as Figure 1-7As shown, a contact heat dissipation motor of the present invention includes a motor body 1, and the motor body 1 includes a motor housing 51, a stator 52, a rotor 53 and an output shaft 54 installed in the motor housing 51, and a base is installed on the motor housing 51 12. The exterior of the motor casing 51 is integrally formed with a plurality of heat-conducting protrusions 11 in the axial direction, and the heat-absorbing cover 3 is installed on the motor casing 51. The heat-absorbing cover 3 includes a plurality of heat-absorbing strips and connecting rings 35, wherein the heat-absorbing strips are Copper blocks, and the top of the heat-absorbing strip has multiple slits, the heat-absorbing strip is fixedly installed on the connecting ring 35, the two ends of the motor housing 51 are integrally formed and the coaxial center is provided with a mounting ring 15, and the connecting ring 35 is sleeved on the mounting ring 35. On the ring 15, a be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com