Superfine fiber fabric and manufacturing process thereof

A technology of microfiber and manufacturing process, applied in textile and papermaking, fabric surface trimming, other household appliances, etc., can solve the problems of resin impregnation, difficulty in dyeing and deep processing, expensive equipment investment, affecting application, etc., and improve product market competition. Power, expand the scope of application, good effect of two-color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

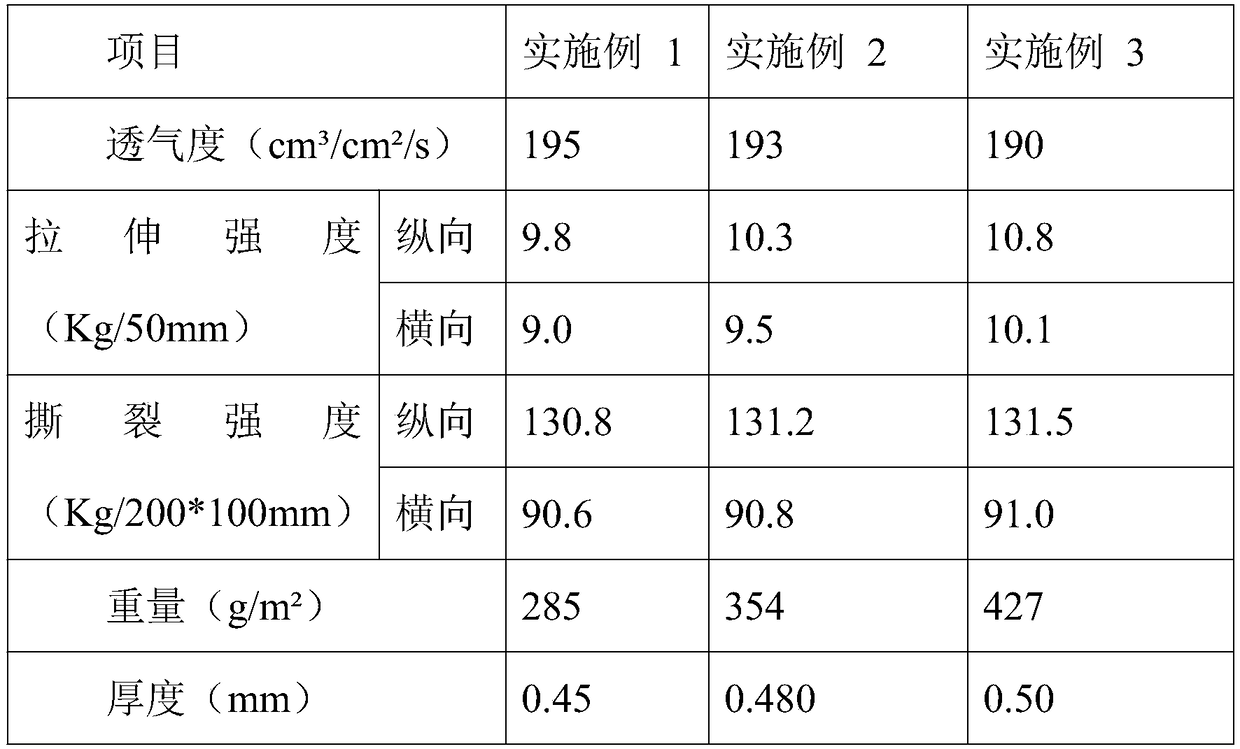

Embodiment 1

[0038] A kind of superfine fiber fabric of the present embodiment, the raw material of superfine fiber fabric is a kind of following raw material combination:

[0039] Base part: 75D polyester sea-island filament and 75D polyester high-strength yarn; surface part: polyester sea-island staple fiber; or,

[0040] Base part: 75D nylon sea-island filament and 75D polyester high-strength yarn; surface part: polyester sea-island staple fiber; or,

[0041] Base part: 75D polyester sea-island filament, 50D polyester filament and 75D polyester high-strength yarn; surface part: polyester sea-island staple fiber; or,

[0042] Base part: 75D polyester sea-island filament and 75D polyester high-strength yarn; surface part: nylon sea-island staple fiber; or,

[0043] Base part: 75D nylon sea-island filament and 75D polyester high-strength yarn; surface part: nylon sea-island staple fiber; or,

[0044] Base part: 75D polyester sea-island filament, 50D nylon filament and 75D polyester high-st...

Embodiment 2

[0067] A kind of superfine fiber fabric of the present embodiment, the raw material of superfine fiber fabric is a kind of in following raw material combination:

[0068] Base part: 110D polyester sea-island filament and 85D polyester high-strength yarn; surface part: polyester sea-island staple fiber; or,

[0069] Base part: 110D nylon sea-island filament and 85D polyester high-strength yarn; surface part: polyester sea-island staple fiber; or,

[0070] Base part: 110D polyester sea-island filament, 125D polyester filament and 85D polyester high-strength yarn; surface part: polyester sea-island staple fiber; or,

[0071] Base part: 110D polyester sea-island filament and 85D polyester high-strength yarn; surface part: nylon sea-island staple fiber; or,

[0072] Base part: 110D nylon sea-island filament and 85D polyester high-strength yarn; surface part: nylon sea-island staple fiber; or,

[0073] Base part: 110D polyester sea-island filament, 125D nylon filament and 85D poly...

Embodiment 3

[0096] A kind of superfine fiber fabric of the present embodiment, the raw material of superfine fiber fabric is a kind of in following raw material combination:

[0097] Base part: 150D polyester sea-island filament and 100D polyester high-strength yarn; surface part: polyester sea-island staple fiber; or,

[0098] Base part: 150D nylon sea-island filament and 100D polyester high-strength yarn; surface part: polyester sea-island staple fiber; or,

[0099] Base part: 150D polyester sea-island filament, 200D polyester filament and 100D polyester high-strength yarn; surface part: polyester sea-island staple fiber; or,

[0100] Base part: 150D polyester sea-island filament and 100D polyester high-strength yarn; surface part: nylon sea-island staple fiber; or,

[0101] Base part: 150D nylon sea-island filament and 100D polyester high-strength yarn; surface part: nylon sea-island staple fiber; or,

[0102] Base part: 150D polyester sea-island filament, 200D nylon filament and 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com