Grain Quality Measuring Device

A technology for measuring device and grain, which is used in measuring devices, testing moving fluids/granular solids, instruments, etc. It can solve the problems of inability to maintain constant filling density, high viscosity, irregular rotation and transportation of samples, etc., so as to improve quality The effect of measuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

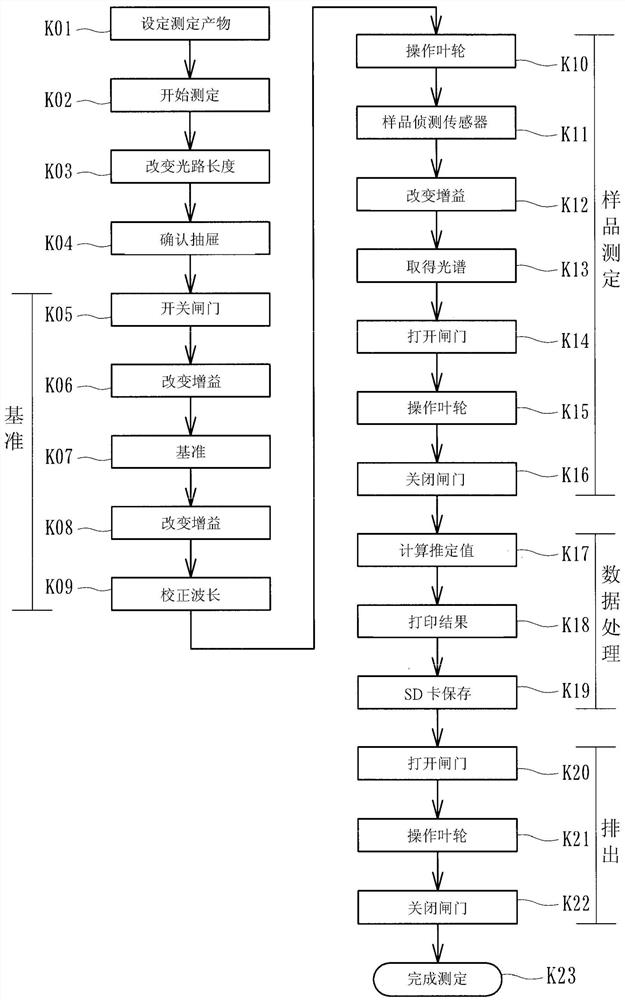

[0031] Preferred embodiments for carrying out the present invention will be described with reference to the accompanying drawings.

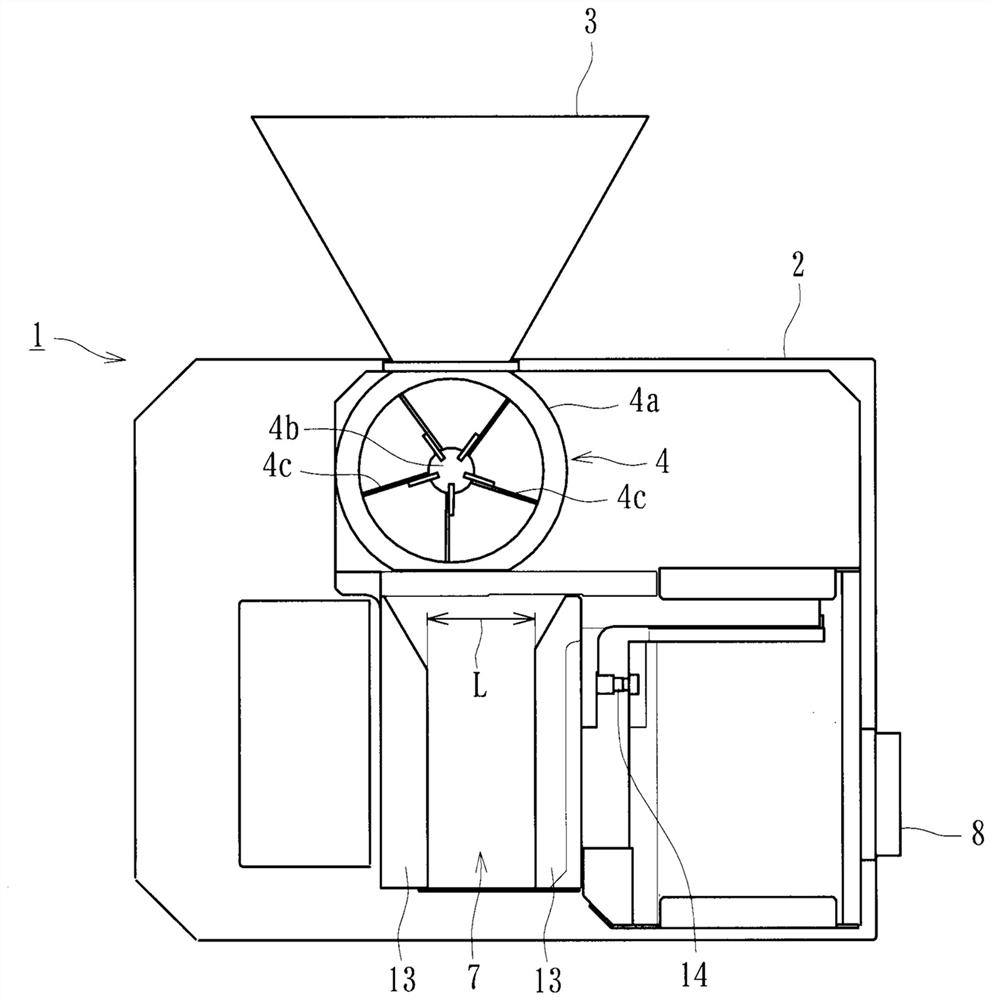

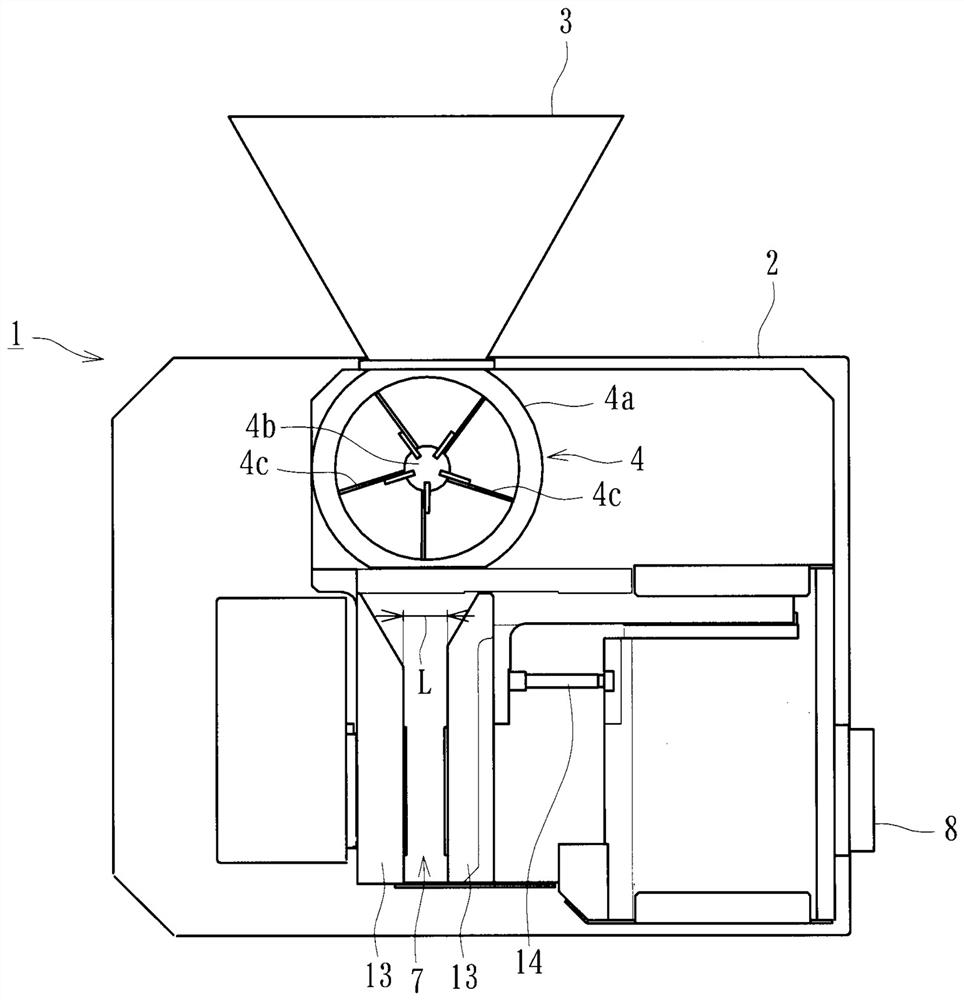

[0032] Figure 1 to Figure 4 An example of the grain quality measuring device of the present invention is shown. Such as figure 1 As shown, the grain quality measurement device 1 includes a box-shaped frame 2, a hopper 3 arranged on the upper surface of the frame 2, and an opening / closing gate (not shown) arranged in an opening formed on the bottom of the hopper 3 .

[0033] The impeller 4 is arranged below the opening formed on the bottom of the hopper 3, and the opening formed on the upper surface of the casing 4a of the impeller 4 communicates with the bottom opening of the hopper 3 via a gate. The gate passes through the control device 15 ( figure 2 The solenoid 5 operated by the control signal of ) is activated and rotated downward, and the sample (grain) thrown into the hopper 3 can be supplied to the impeller 4 . The impeller 4 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com