Continuous measuring method of calcium and barium content in silicon-calcium-barium and silicon-aluminum-calcium-barium alloy

The technology of a silicon-calcium-barium alloy and a determination method is applied in the field of continuous determination of silicon-calcium-barium and barium content in a silicon-aluminum-calcium-barium alloy. The effect of shortening the operation process, low cost and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The above-mentioned and other technical features and advantages of the present invention will be described in more detail below in conjunction with the embodiments.

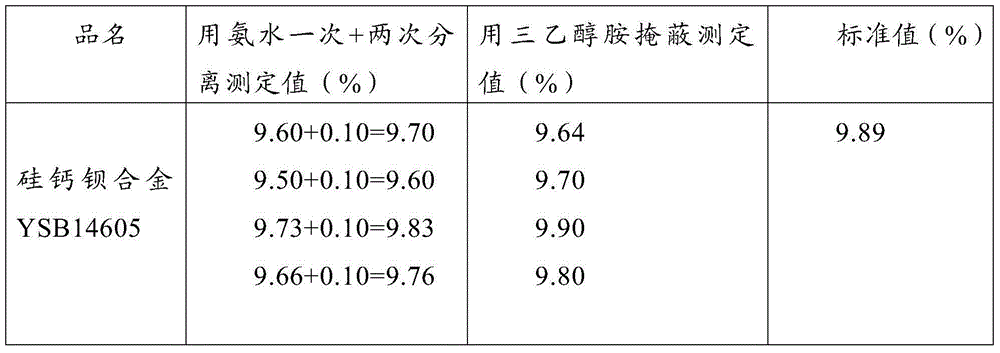

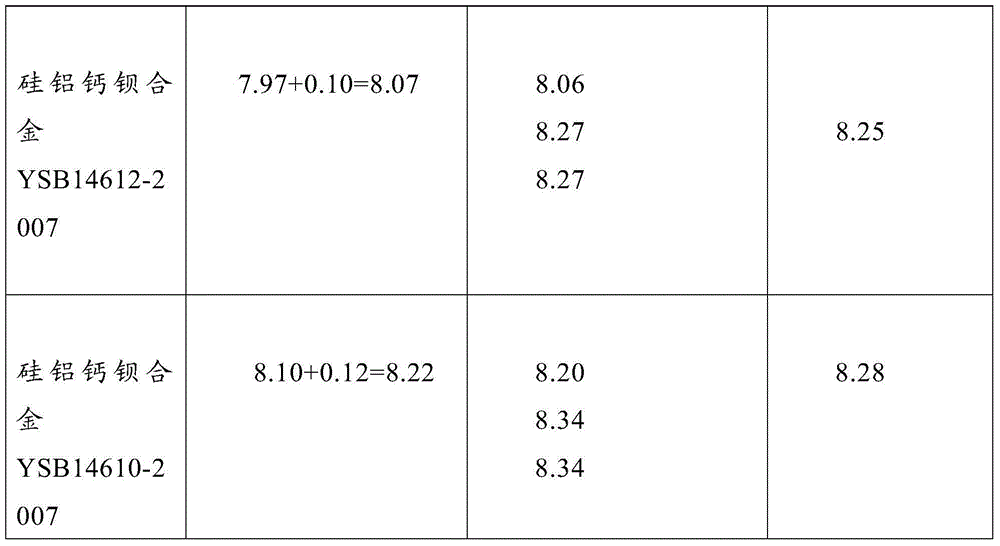

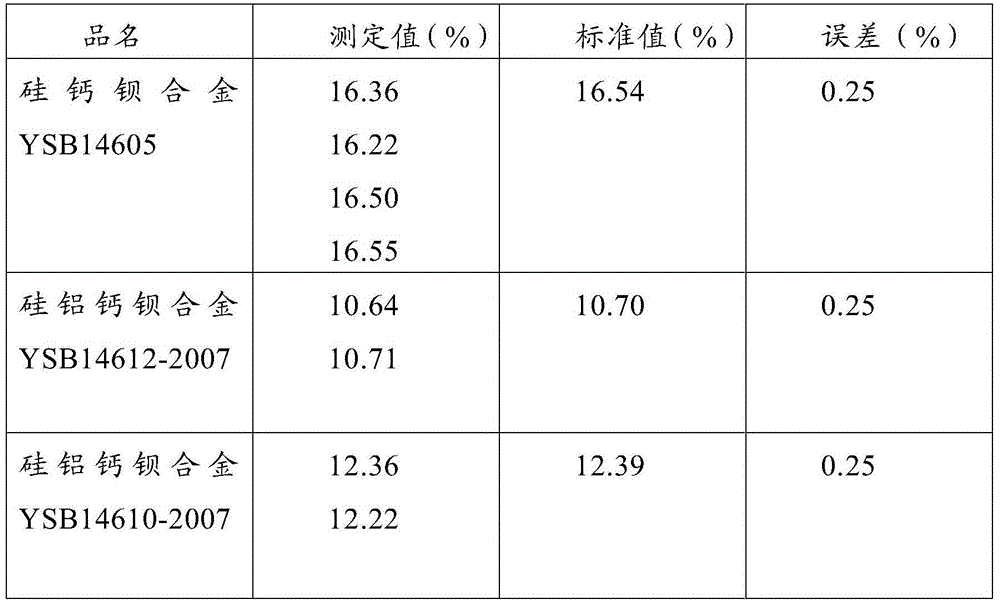

[0029] 1. Summary of the method: Use nitric acid (67%)-hydrofluoric acid (40%) to dissolve silicon-calcium-barium or silicon-aluminum-calcium-barium alloy samples in a polyethylene plastic beaker, add sulfuric acid to smoke and wet salt, remove, After cooling, carefully add 5mL of hydrochloric acid (65%) along the wall of the cup, and heat to dissolve the salts. Add 150 mL of water to the test solution, add a little hydroxylammonium hydrochloride (this step is to mask iron) and heat until the solution turns from yellow to colorless. , the particles are very fine, and will penetrate through the filter without padding, which will affect the determination result of barium.) Filter it into a 250mL volumetric flask, wash the precipitate with 1% sulfuric acid for 6-8 times, and then wash it with water for 9-10 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com