Longitudinal connection method of weld bead in wire and arc additive manufacturing

A technology of additive manufacturing and vertical connection, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of inapplicability and inability to obtain better welding effects, so as to ensure the quality of molding, ensure reliability, and reduce experiments The effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention proposes a method for longitudinally connecting weld beads in arc additive manufacturing, which will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

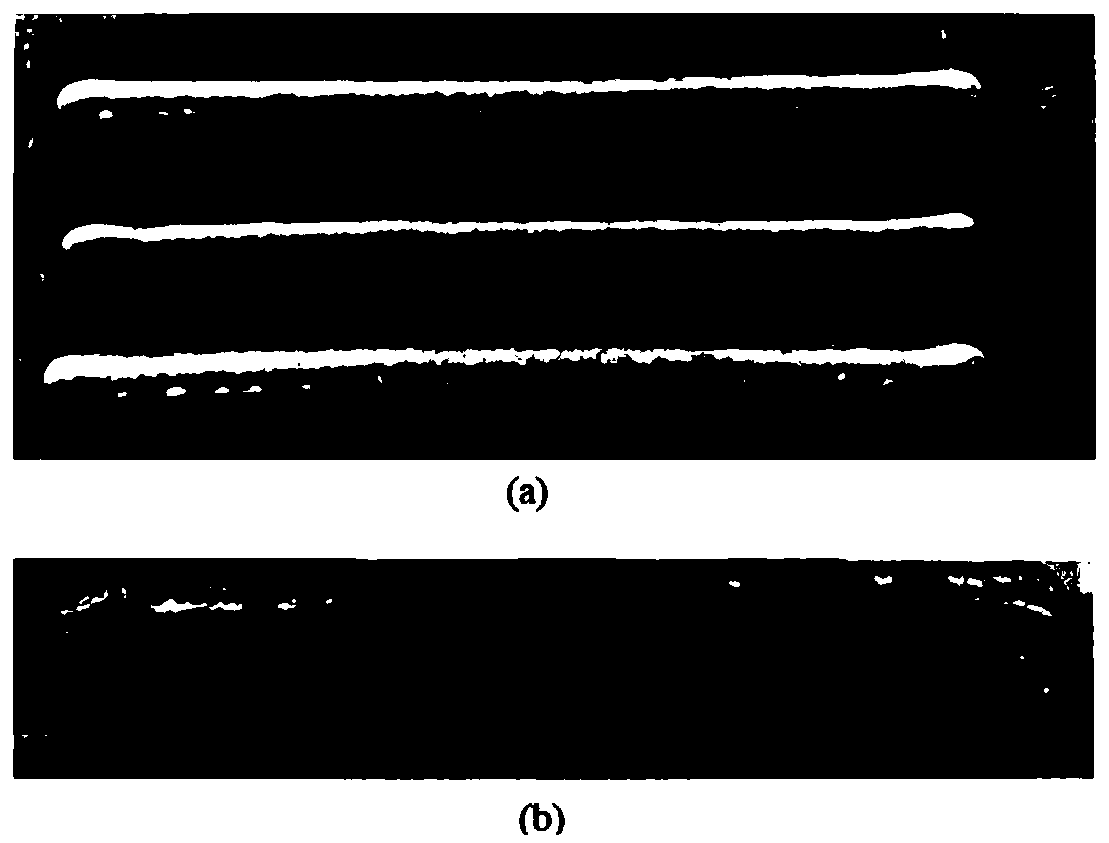

[0033] The invention proposes a longitudinal connection method of welding beads in arc additive manufacturing. "Longitudinal" means that each weld bead is welded on the surface of the previous weld bead, and a weld bead accumulation result with a certain height can be obtained after multiple welding, such as figure 1 as shown ( figure 1 It is a schematic diagram of the longitudinal connection of the welding bead in the arc additive manufacturing in the embodiment of the present invention, wherein figure 1 (a) is a top view, figure 1 (b) main view). The welding process parameters that affect the longitudinal accumulation result are mainly welding speed (moving speed of the welding torch) and wire feeding speed, and the geometric parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com