3D printing precise material distributing robot

A 3D printing and robotics technology, applied in manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc., can solve the problems of printed product detection, easy infringement of property rights, etc., to achieve fast running speed, convenient search and comparison , the effect of improving transmission speed and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

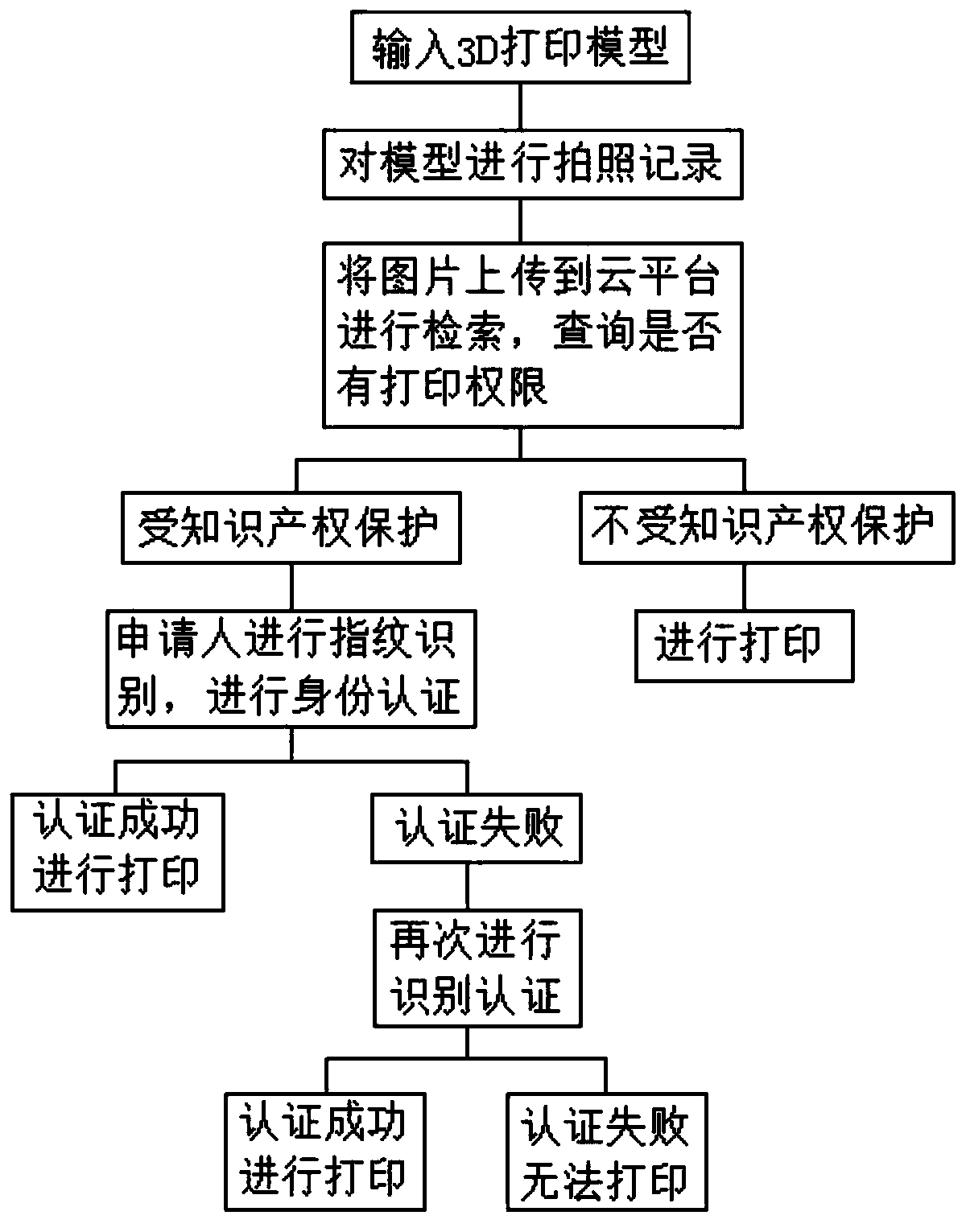

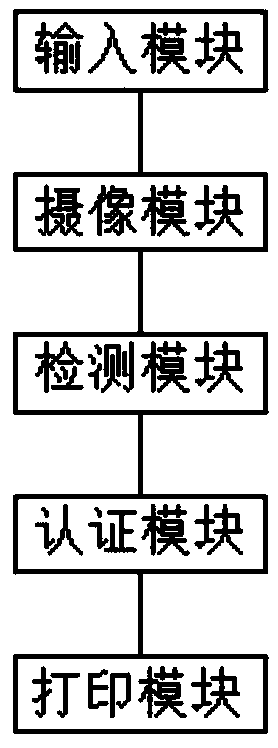

[0039] see Figure 1-2 , a 3D printing precision cloth robot, including an input module, a camera module, a detection module, an authentication module and a printing module, the input module is used to input the target model to be printed, and the input module includes a host computer that accepts data and processes it, The printing module is used to print the input target model, and the printing module includes a lower host computer and a model printing device for controlling the printing movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com