Simulated analysis device and method for pressure regulation and ventilation of multi-level goaf of coal seam group

A simulation analysis, goaf technology, applied in mining installations, mine/tunnel ventilation, mining equipment, etc., can solve problems such as high commissioning costs, lack of reasonable parameters and pressure regulation effects, and large errors in the selection of pressure regulation parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

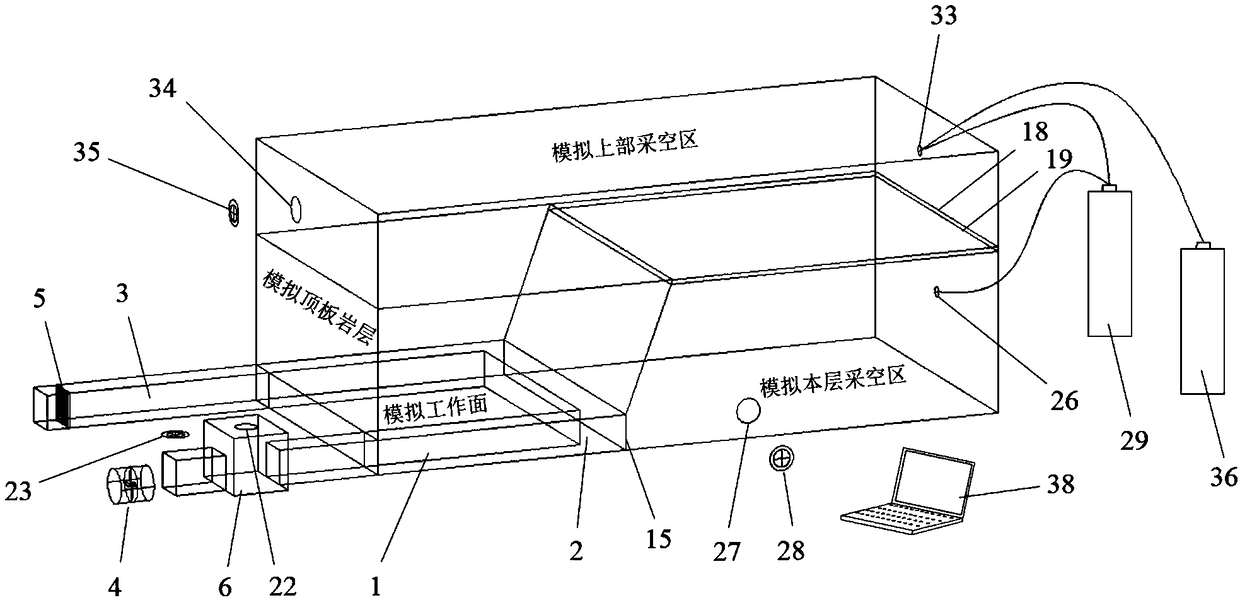

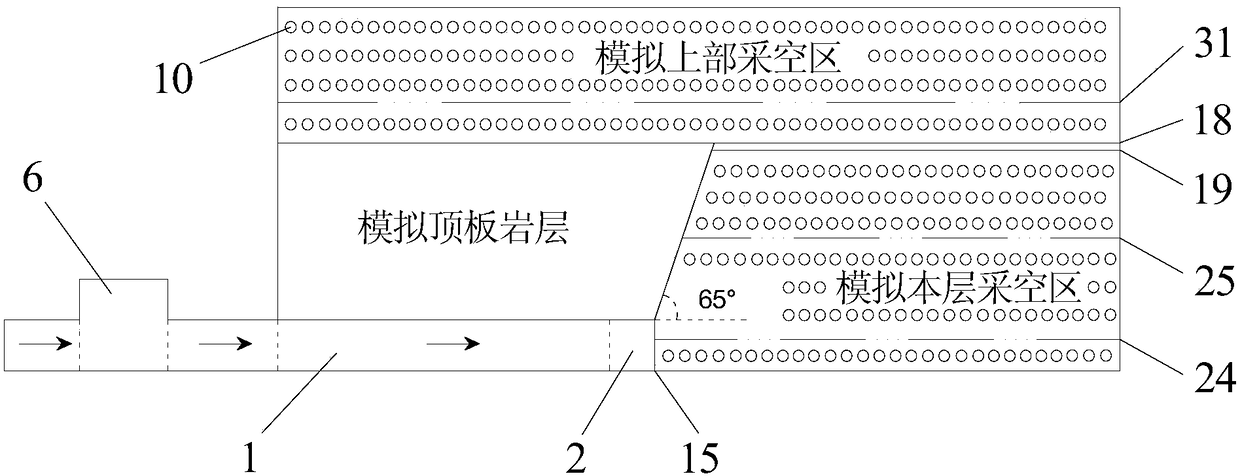

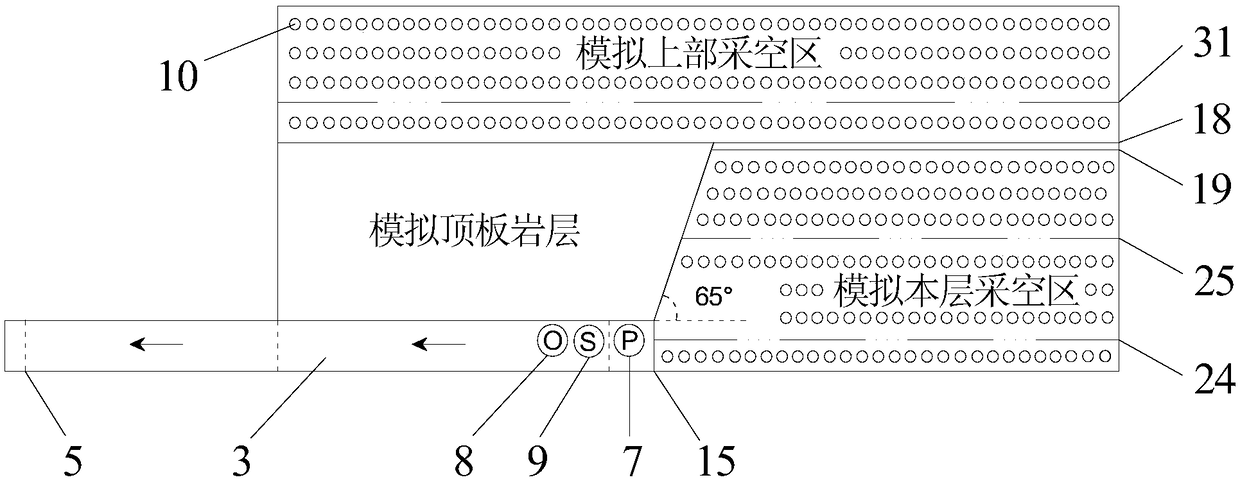

[0071] A simulation analysis device for pressure regulation and ventilation in multi-layer gobs of coal seam groups, the schematic diagram of its three-dimensional structure is shown in figure 1 , specifically including simulating the working face, simulating the roof strata, simulating the goaf in this layer, and simulating the upper gob;

[0072] in,

[0073] (1) The simulated working face includes air inlet pipeline 1, coal mining face pipeline 2, air return lane pipeline 3, simulated air window 5, colored smoke release box 6, and wind pressure sensor of simulated working face 7. The oxygen concentration sensor 8 of the simulated working face and the sulfur hexafluoride concentration sensor 9 of the simulated working face;

[0074] The air inlet pipeline 1 and the air return pipeline 3 are respectively arranged on both sides of the simulated working face, and are connected through the coal mining face pipeline 2, and the colored smoke release box is arranged at the air inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Gap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com