Method for increasing sintering efficiency of FeSe superconducting material

A technology of superconducting material and efficiency, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problem of slow sintering of FeSe superconducting materials, achieve good intergranular connectivity, improve efficiency, and improve the uniformity of the structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

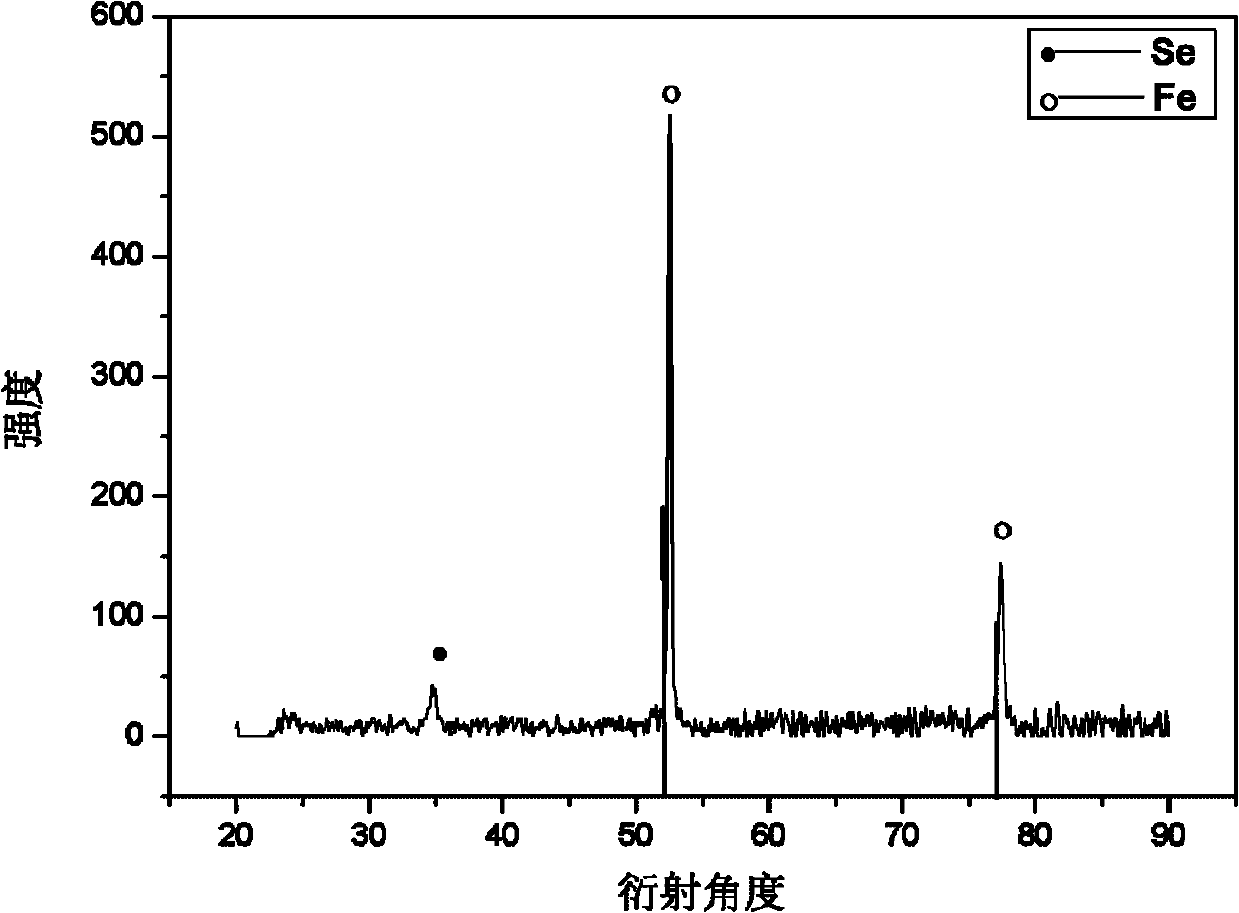

[0033] Select Fe powder (purity is 99.99%) and Se powder (purity is 99.99%), mix according to atomic weight ratio 1: 0.95, then put the mixed powder into polyurethane ball milling tank, put into the ball milling tank with a diameter of 6mm stainless steel Steel balls, the mass ratio of ball powder is 20:1; filled with 0.15MPa argon, put it into a ball mill, and conduct ball milling under the protection of inert gas argon for 50h; then make thin slices under a pressure of 2MPa for 10 minutes. In the XRD spectrum, it can be seen that the diffraction peak of Se in the treated powder sample nearly disappears, and the diffraction peak of Fe shifts, indicating that Se has entered the lattice of Fe to form a solid solution, and the direct contact area between Se and Fe is larger.

Embodiment 2

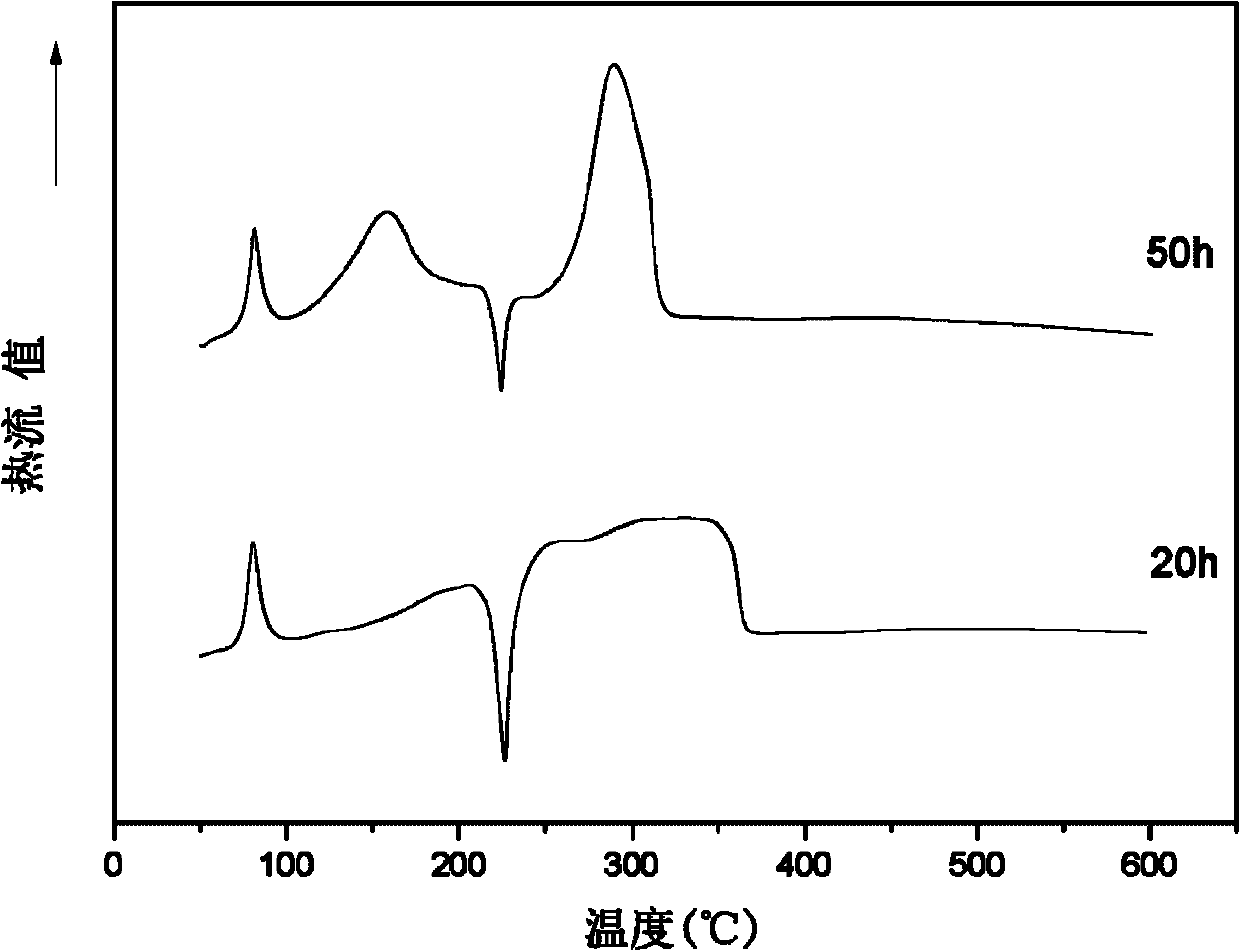

[0035]Select Fe powder (purity is 99.99%) and Se powder (purity is 99.99%), mix according to the atomic weight ratio 1:1, then put the mixed powder into the polyurethane ball mill jar, and put the stainless steel with a diameter of 6mm in the ball mill jar Steel balls, the mass ratio of ball powder is 15:1; after filling with 0.1MPa argon gas, put it into the ball mill, and carry out ball milling under the protection of inert gas argon for 20h; then hold the pressure at 6MPa for 6 minutes to make thin slices, Put the slice into a high-temperature differential scanner, and conduct differential thermal analysis under an argon protective atmosphere with a flowing pressure of 0.06MPa. The heating rate is 5°C / min. After rising to 600°C, cool at a cooling rate of 20°C. Bring to room temperature. Compared with the untreated powder, the two reaction peaks move to the low temperature direction, the reaction advances, the reaction interval becomes smaller, and the reaction becomes more ...

Embodiment 3

[0037] Select Fe powder (purity is 99.99%) and Se powder (purity is 99.99%), mix according to atomic weight ratio 1: 0.95, then put the mixed powder into polyurethane ball milling tank, put into the ball milling tank with a diameter of 6mm stainless steel Steel balls, the mass ratio of ball powder is 10:1; after filling with 0.15MPa argon gas, put it into the ball mill, and conduct ball milling under the protection of inert gas argon for 50h; then keep the pressure at 0.05MPa for 2 minutes to make thin slices , put the slice into a high-temperature differential scanner, and conduct differential thermal analysis under an argon protective atmosphere with a flowing pressure of 0.07MPa. The heating rate is 5°C / min. After rising to 600°C, the cooling rate is 10°C Cool down to room temperature. It can be seen from the DSC curve that the two reaction exothermic peaks have been separated, one has been advanced before the melting of Se, indicating that the reaction has already occurred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com