Spherical slope type two-way overrunning clutch

An overrunning clutch, ramp technology, applied in one-way clutches, clutches, mechanical equipment, etc., can solve the problem of inability to realize the drive of the follower, achieve great economic application value, novel structure, and increase the effect of torque generators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

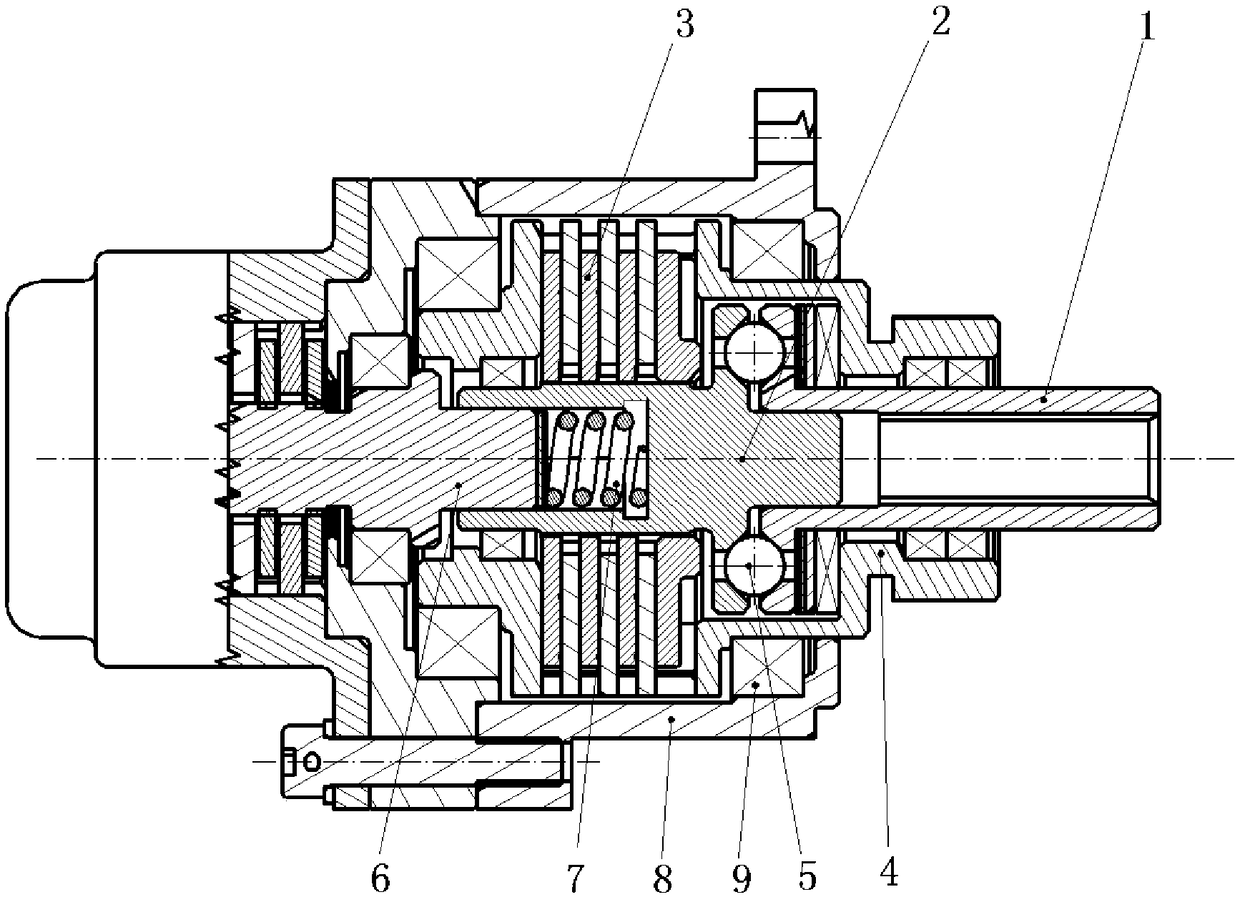

[0013] The slope type two-way overrunning clutch of the present invention includes components such as a driving element 1, an intermediate shaft 2, a friction assembly 3, a driven element 4, steel balls 5, a torque generator assembly 6, a spring 7 and a bearing 9. The active part 1 is connected with the intermediate shaft 2 through the steel ball 5, and the spring 7 presses the intermediate shaft 2 to make it close to the active part 1. The steel ball 5 is installed in the tapered hole on the end surface of the active part 1 and the intermediate shaft 2 . The other end of the intermediate shaft 2 is connected to the torque generator 6 through splines, and is associated with the driven member 4 through the friction assembly 3 in the middle area. The friction assembly 3 is composed of a dynamic friction plate and a static friction plate, the static friction plate is connected with the intermediate shaft 2 through a spline, and the dynamic friction plate is connected with the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com