A kind of automobile marking lamp and its production process

An automotive logo and process technology, applied in the field of auto parts, can solve the problems that the panel cannot guarantee surface roughness, cannot guarantee firmness, and is not easy to disassemble, and achieves the effects of improving aesthetics, long service life, and convenient connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

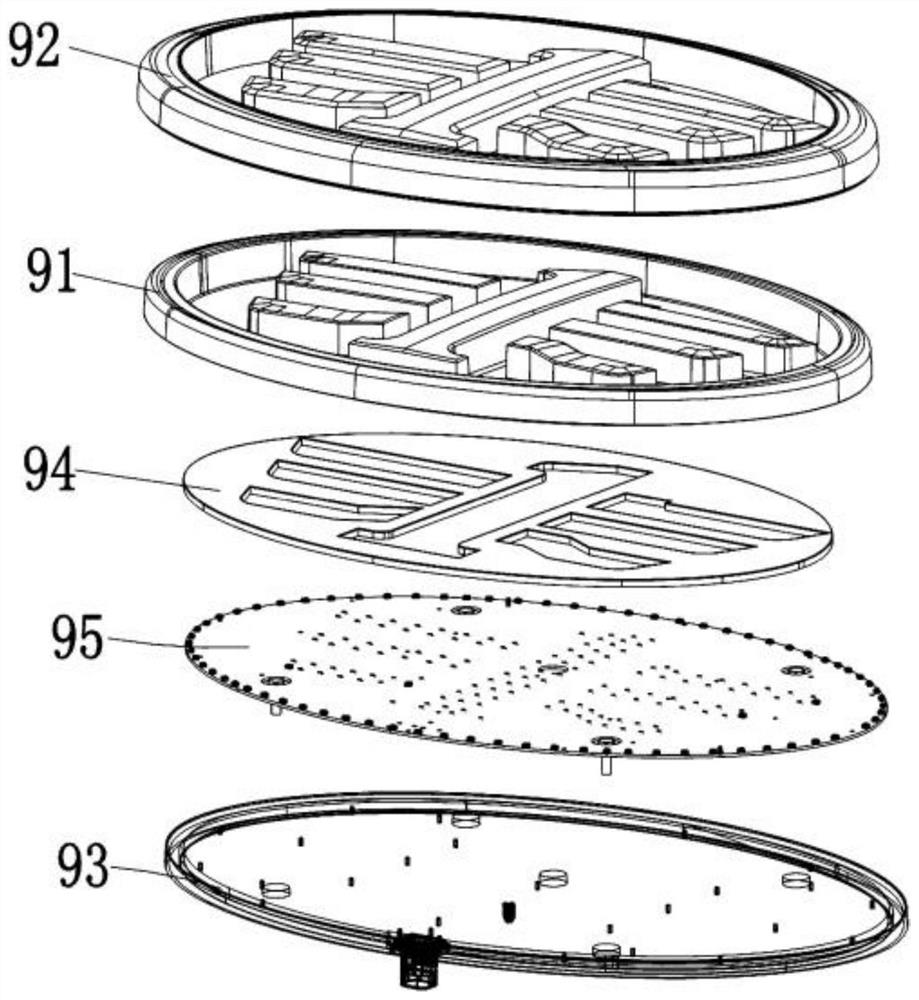

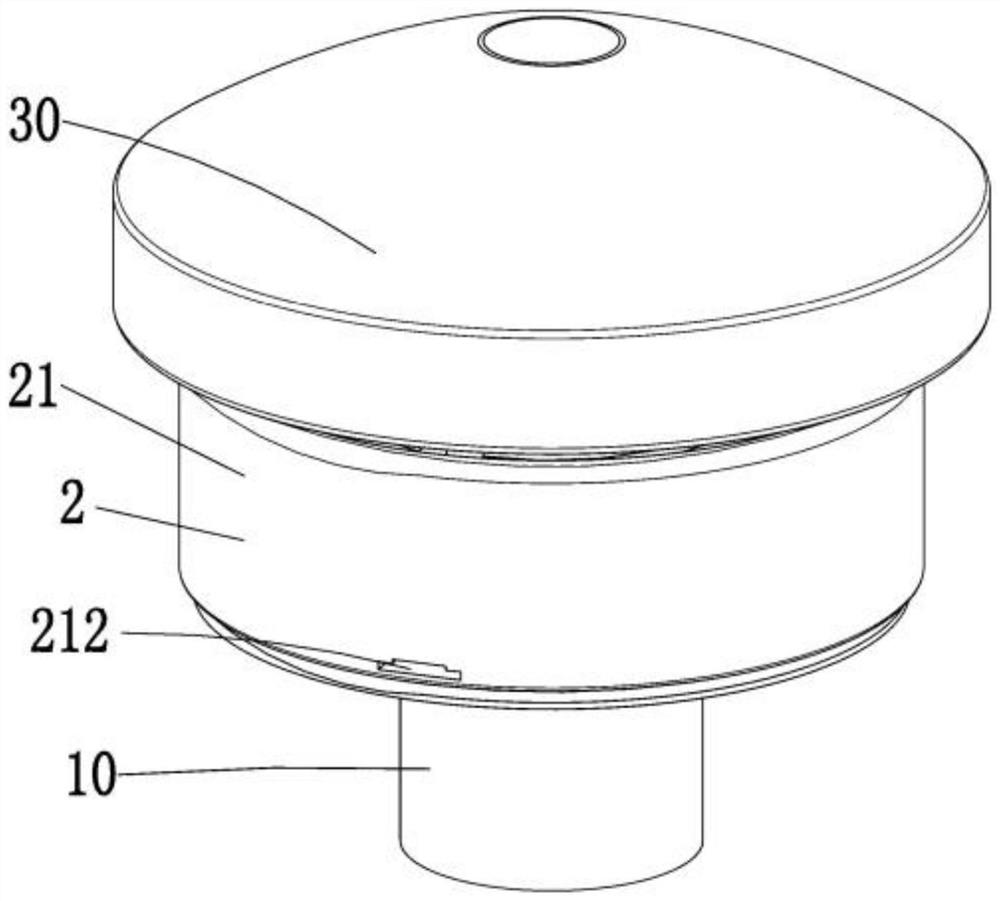

[0040] Such as Figure 1-13 As shown, a kind of automobile logo lamp comprises a mask 92, a diffuser mask 94, a decorative plate 91 connected to the diffuser mask 94 on one side and connected to the diffuser mask 94 on one side, and a housing connected to the diffuser mask 94 93, a circuit board 95 and a plurality of lamp beads 30 are arranged between the housing 93 and the diffusion mask 94, and the lamp beads 30 are electrically connected to the circuit board 95 through circuit board pins 10; the lamp The bead 30 is connected to the pin 10 of the circuit board through a connection structure 2, wherein the diffusion mask 94 is an aluminum layer,

[0041]The specific connect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap