A filter cloth dehumidification control system

A control system and filter cloth technology, which can be used in drying gas arrangement, non-progressive dryer, lighting and heating equipment, etc., and can solve the problems of easy mold and high moisture content of filter cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

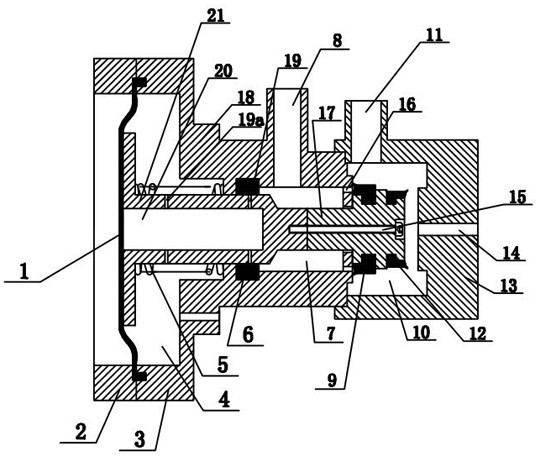

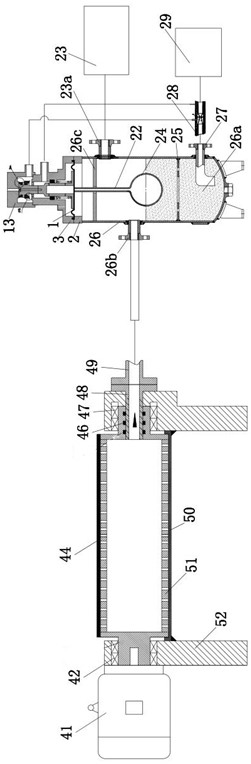

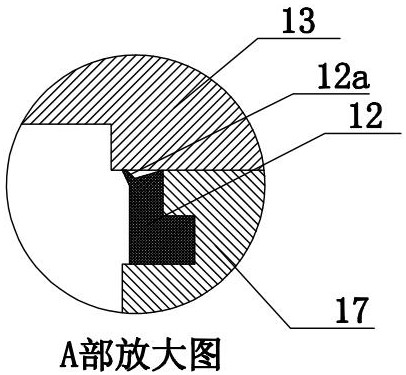

[0027] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0028] As shown in the figure, the filter cloth dehumidification control system includes a micro-control device and a filter cloth dehumidification device. The lower part of the micro-control device is equipped with a condensed water collector 26, and the lower part of the condensed water collector 26 is a condensed water collection tank 26a. The pool 26a is connected with the filter cloth dehumidification device through the condensed water collecting joint 26b. The condensed water collecting pool 26a is equipped with a floating ball 24, the floating ball 24 is equipped with a push rod 22, and the lower part of the condensed water collecting pool 26a is equipped with a sewage discharge joint 27. The joint 27 is connected with one end of the discharge pipe 28, and the other end of the discharge pipe 28 is connected with the negative pressure station 29...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com