Method for performing horizontal measurement on product airfoil structure by using three-dimensional laser scanning system

A three-dimensional laser and level measurement technology, applied in the field of measurement, can solve the problems of low measurement accuracy and low efficiency, and achieve the effects of reliable measurement process, high operation efficiency, and saving design, manufacturing and management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

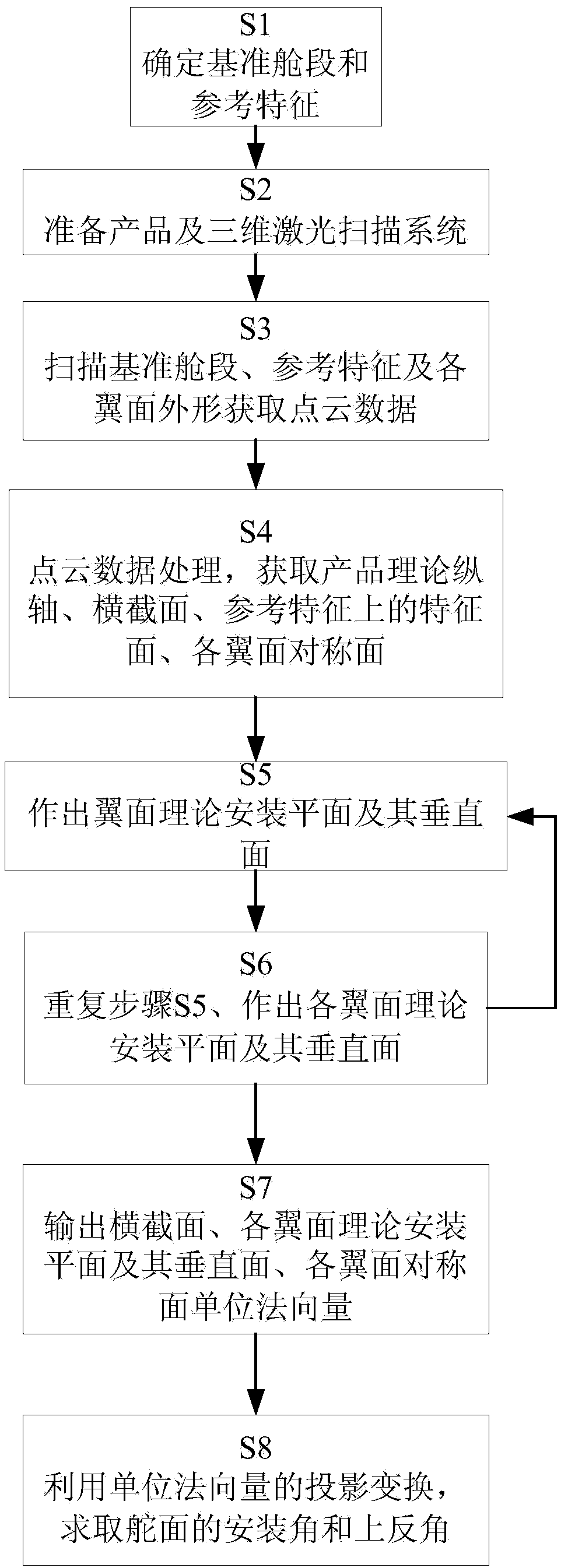

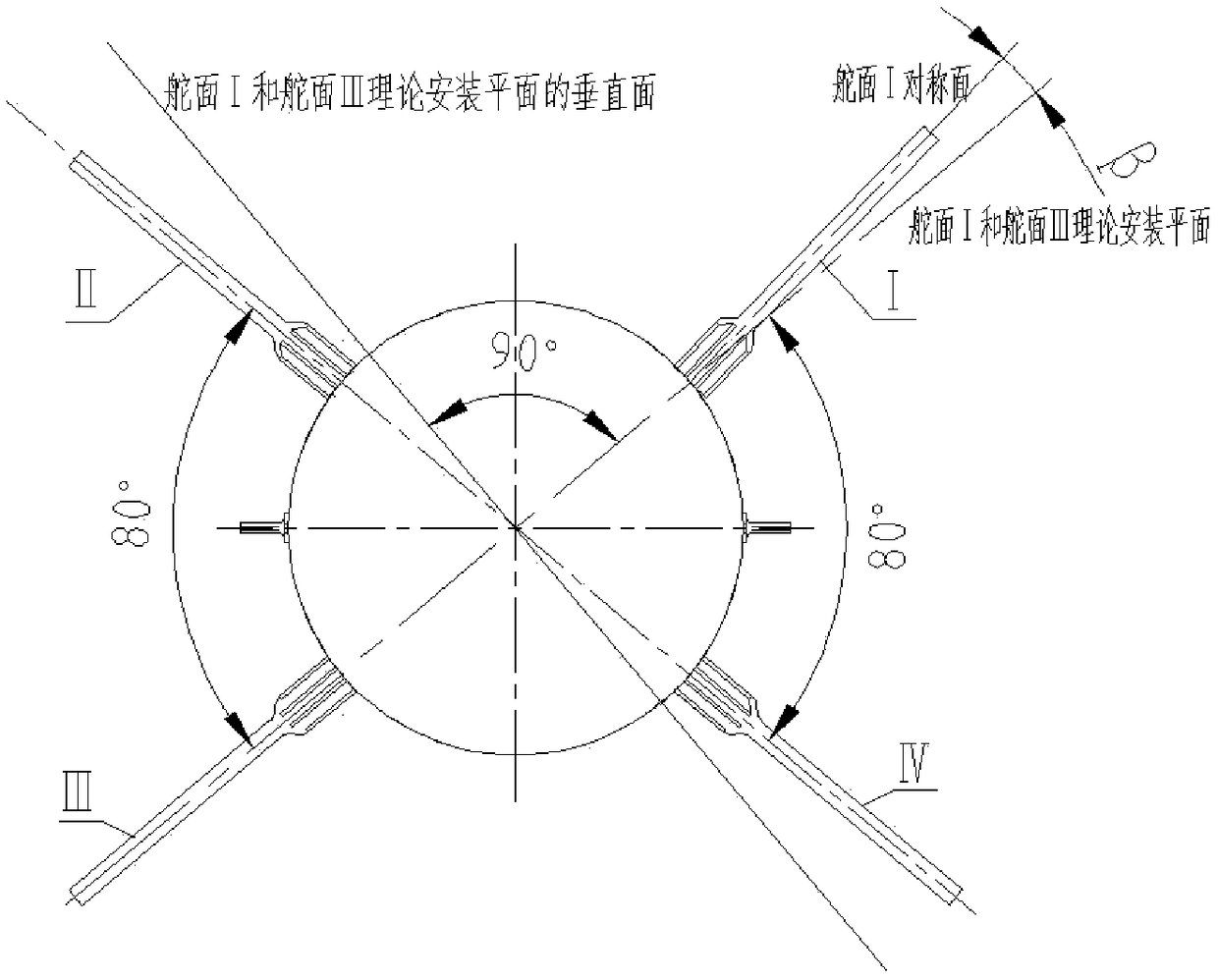

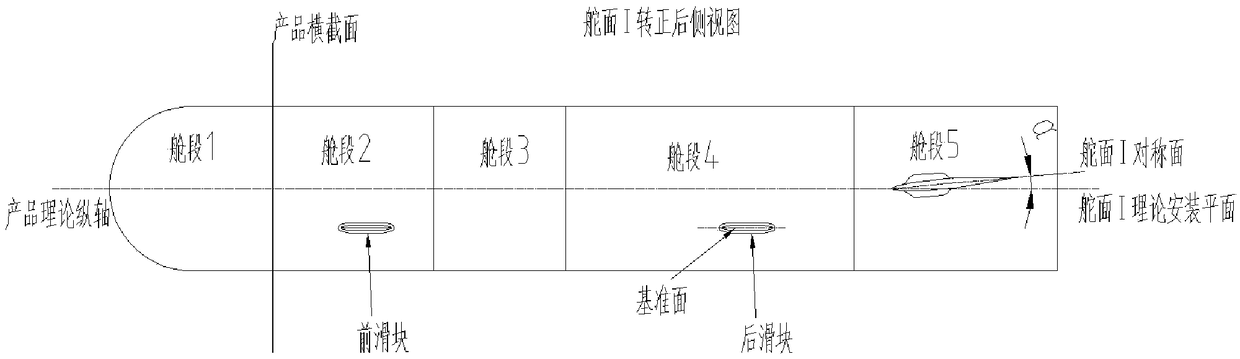

[0037] The specific embodiment is carried out according to the following process steps:

[0038] The first step is to determine the reference cabin and reference features: because the product horizontal measurement reference section is set on the cabin 2 and cabin 4 in the design, the cabin 2 and cabin 4 are selected as the reference cabin to obtain the product’s Theoretical longitudinal axis; because the relative positional relationship between the slider and the product has high machining accuracy, and the symmetry plane of the slider coincides with the horizontal plane of the product, the slider is selected as a reference feature to obtain the theoretical installation plane of the rudder surface.

[0039] The second step is to prepare the product and the 3D laser scanning system: hoist the product to a reliable support on the support vehicle, and place the 3D laser scanning system near the product.

[0040] The third step of scanning: set the scanning resolution of the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com