A laser light source and a laser projection system

A laser light source and laser technology, applied in the field of optics, can solve the problems of not meeting the development requirements of lasers, high cost, complex optical structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

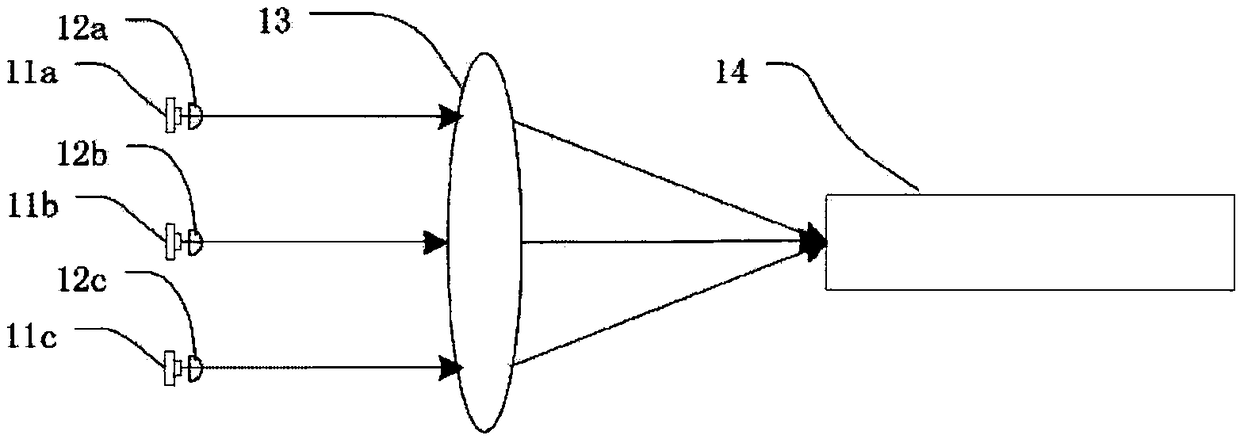

Embodiment 1

[0063] The laser exit is rectangular with an aspect ratio of 16:10. The DMD light valve has a rectangular shape with an aspect ratio of 16:9. The entrance and exit of the light rod are both rectangular, with the side parallel to the X axis as the horizontal side and the side parallel to the Y axis as the vertical side. The aspect ratio of the light bar entrance is 9:16, and the aspect ratio of the exit port is 16:9.

[0064] In the first embodiment, since the size of the entrance of the light rod does not completely correspond to the size of the exit of the laser, the light beam emitted from the laser cannot be collected efficiently.

Embodiment 2

[0066] The laser exit is rectangular with an aspect ratio of 16:10. The DMD light valve has a rectangular shape with an aspect ratio of 16:9. Both the entrance and exit of the light rod are rectangular, the aspect ratio of the entrance is 10:16, and the aspect ratio of the exit is 16:10. The length of the light rod is 20+ / -0.2mm.

[0067] In the second embodiment, due to the short length of the light rod, the uniform light effect is not optimal. At the same time, the size of the exit port does not exactly match the DMD, so the beam cannot be used efficiently.

Embodiment 3

[0069] The laser exit is rectangular with an aspect ratio of 16:10. The DMD light valve has a rectangular shape with an aspect ratio of 16:9. Both the entrance and exit of the light rod are rectangular, the aspect ratio of the entrance is 10:16, and the aspect ratio of the exit is 16:9. The length of the light rod is 35+ / -0.2mm.

[0070] If the optical rod is a hollow barrel structure, specifically, the inner diameter of the entrance is 6.8+ / -0.1mm×4.2+ / -0.1mm, and the outer diameter is 9+ / -0.2mm×6.4+ / -0.2mm; the size of the inner diameter of the exit port is 3.5+ / -0.1mm×5.6+ / -0.1mm, and the size of the outer diameter is 5.35+ / -0.2mm×7.8+ / -0.2mm.

[0071] In embodiment three, the size of each part of the light rod matches the existing optical device, that is, the entrance of the light rod matches the size of the laser exit port, and the exit port of the light rod matches the light valve of the DMD, so that the difference in beam divergence angle is obtained Optimization, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com