Integrated luminous identification

A technology for luminous signs and light sources, applied in the field of signs, can solve the problems of discount of overall visual effect, poor light absorption, lack of beauty and texture, etc., and achieve the effect of simple and convenient light source setting, reducing workload and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

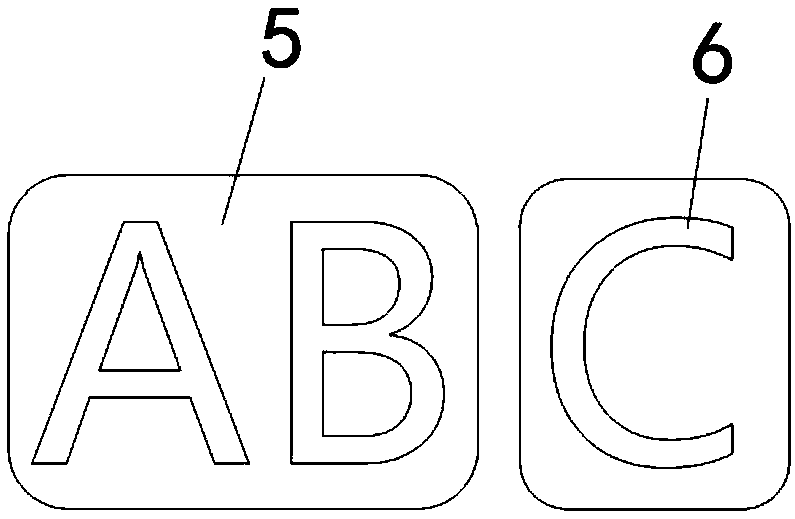

[0075] like Figure 1A-Figure 1F As shown, this embodiment intends to provide an integrated light-emitting sign. The light-emitting sign is a character pattern displaying "ABC", which is divided into two parts "AB" and "C" according to the plan, and each part corresponds to a set of light sources. In this way, the "AB" character pattern can be distinguished from "C" in light color and brightness effect. This embodiment includes: a plate-shaped base, that is, a substrate 1 , a panel 2 , an LED strip light source 3 , a light-transmitting member 4 and a light guide plate 5 . Wherein, the LED strip light source 3 is a plurality of patch LED light sources welded on a circuit board, and the circuit board is a flexible circuit board and / or a hard circuit board.

[0076] The substrate 1 plays the role of carrying the panel 2 , the light guide plate 5 and the light source 3 .

[0077] Two mounting grooves 12 are provided on the base plate 1. The mounting grooves 12 here belong to a b...

Embodiment 2

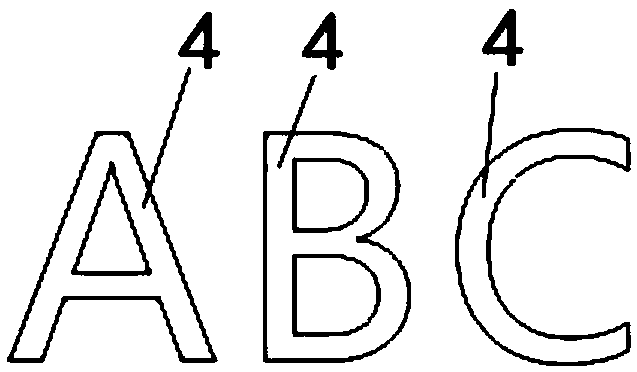

[0086] like Figure 2A-Figure 2D As shown, this embodiment intends to provide an integrated light-emitting sign, the light-emitting sign is a character pattern displaying "ABC", and is divided into three parts "A", "B" and "C" according to the plan, and each part corresponds to A set of light sources, so that the character patterns of "A" and "B" and "C" can be set with different light colors and brightness. This embodiment includes: a plate-shaped base, that is, a substrate 1 , a panel 2 , an LED strip light source 3 , a light-transmitting member 4 and a light guide plate 5 .

[0087] The differences between this embodiment and Embodiment 1 are: 1. The three mounting grooves 12 of the substrate 1 are through-groove structures, the upper grooves of the mounting grooves 12 cover the panel 2, and the lower grooves are provided with a light-shielding and reflective base plate 8; 2. , the fronts of the three light guide plates 5 are respectively provided with hollow out grooves 9...

Embodiment 3

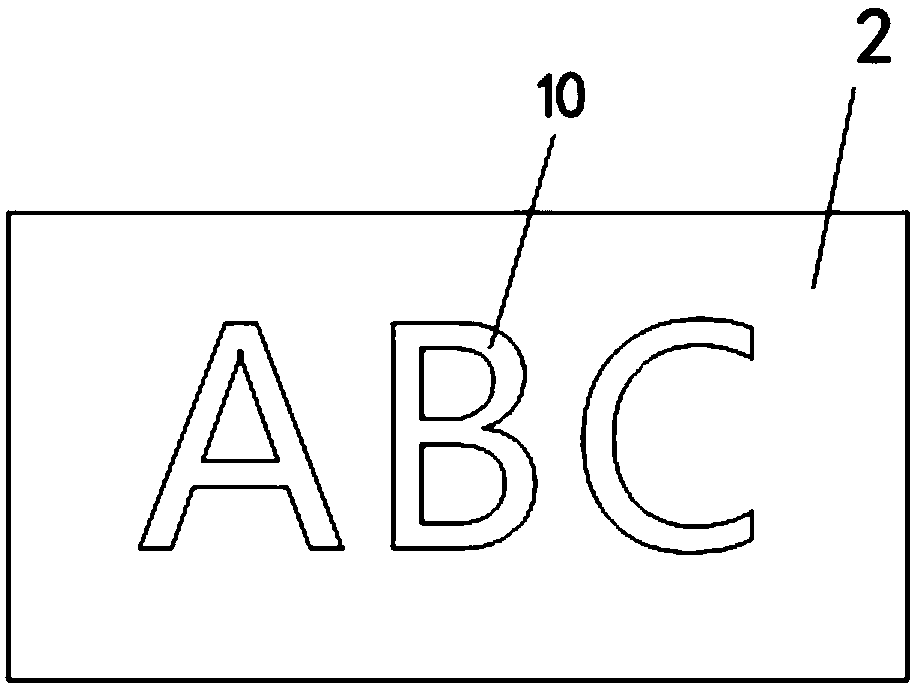

[0090] like Figure 3A-Figure 3D As shown, this embodiment intends to provide an integrated light-emitting sign, the light-emitting sign is a character pattern displaying "ABC", and "ABC" corresponds to a set of light sources, so that the light color and brightness of the three character patterns can be guaranteed to be consistent. This embodiment includes: a plate-shaped base, that is, a substrate 1 , a panel 2 , an LED strip light source 3 , a light-transmitting member 4 and a light guide plate 5 .

[0091] This embodiment differs from the above embodiments in that: 1, the installation groove 12 on the substrate 1 is a through groove structure without a bottom plate; 2, the three character pattern engraved grooves 6 are arranged on the back side of the light guide plate 5 (on the light guide plate 5 The side away from the panel), the back notch of the hollow groove 10 on the panel 2 is docked at the corresponding position on the front of the light guide plate 5, and this pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com