Matrix-type socket

A matrix and socket technology, applied in contact parts, electrical components, coupling devices, etc., can solve the problems of complex structure and high cost, and achieve the effect of solving radial tolerance, reducing production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

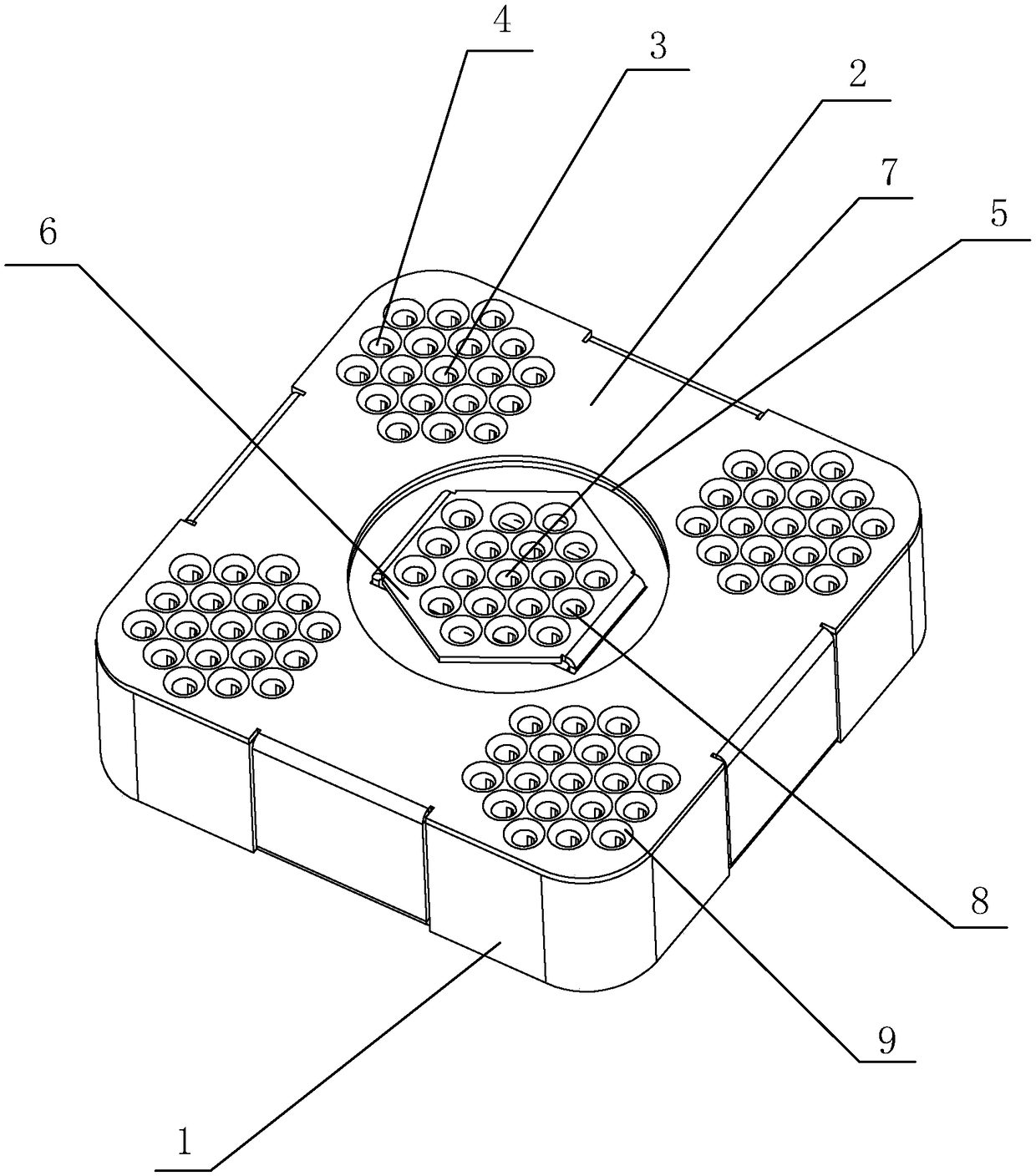

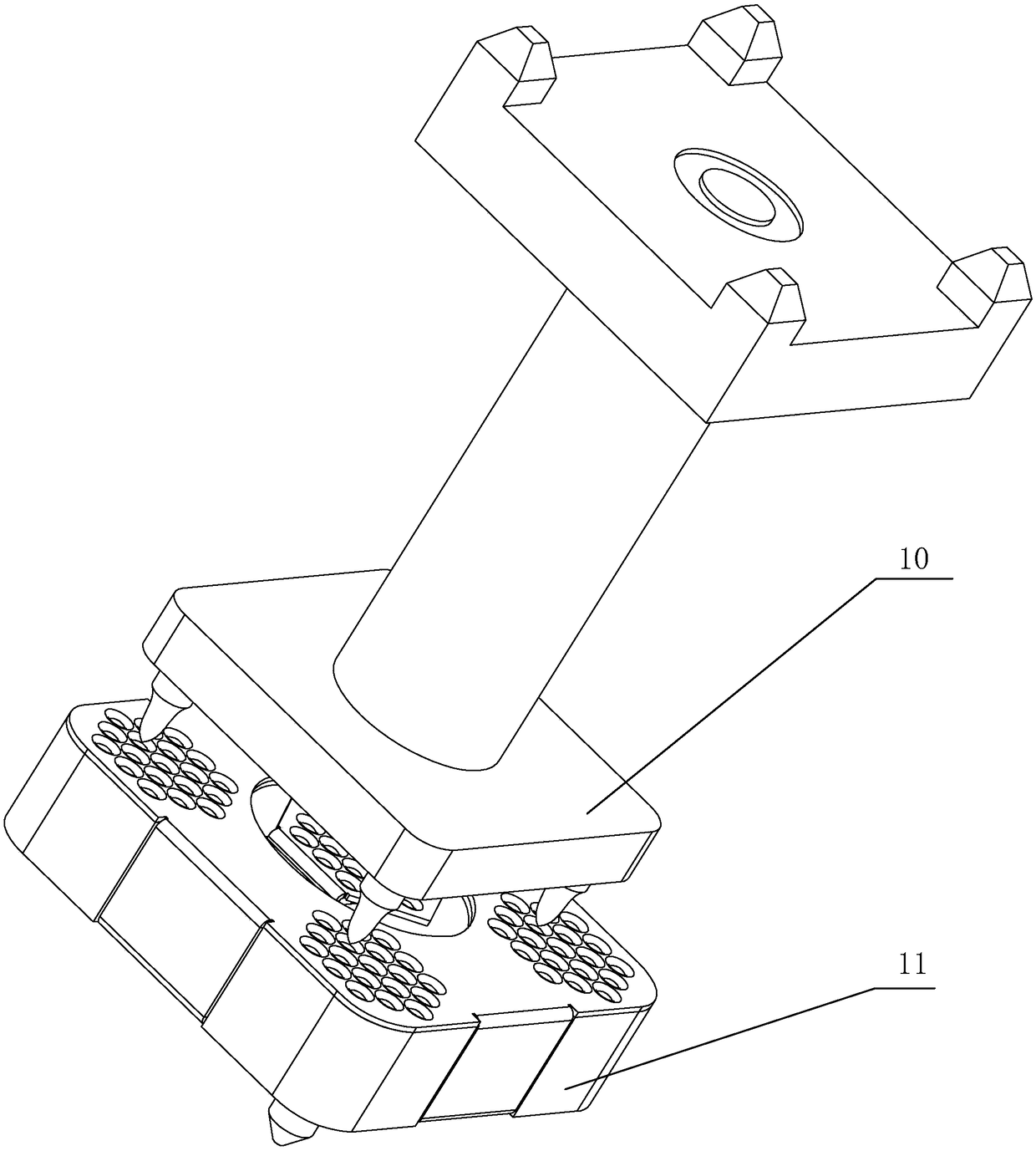

[0020] Embodiment one: see Figure 1~2 As shown, a matrix socket includes a body 11, one end of the body 11 is welded on the PCB main board, and the other end is electrically connected to a multi-pin radio frequency plug 10, the body 11 includes a base 1 and a grounding reed 2, The grounding reed 2 is snap-connected to the base 1, and several groups of jack components are arranged on the grounding reed 2, and the positions of the jack components are adapted to the positions of the multi-pin radio frequency plug 10, each A group of jack components includes a plurality of conductive connecting holes, and one end of the conductive connecting holes in the same group is connected in parallel to the output end of the group of jack components. The product has simple structure and convenient connection, and the production cost of the product is greatly reduced.

[0021] see figure 1 As shown, a conductive connection hole in each group of the jack assembly is set as the central conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com