Feeding robot for breeding

A feeding robot and weighing technology, applied in the field of breeding, can solve the problems of accumulation inside the robot, failure to ensure the amount of feed, robot damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

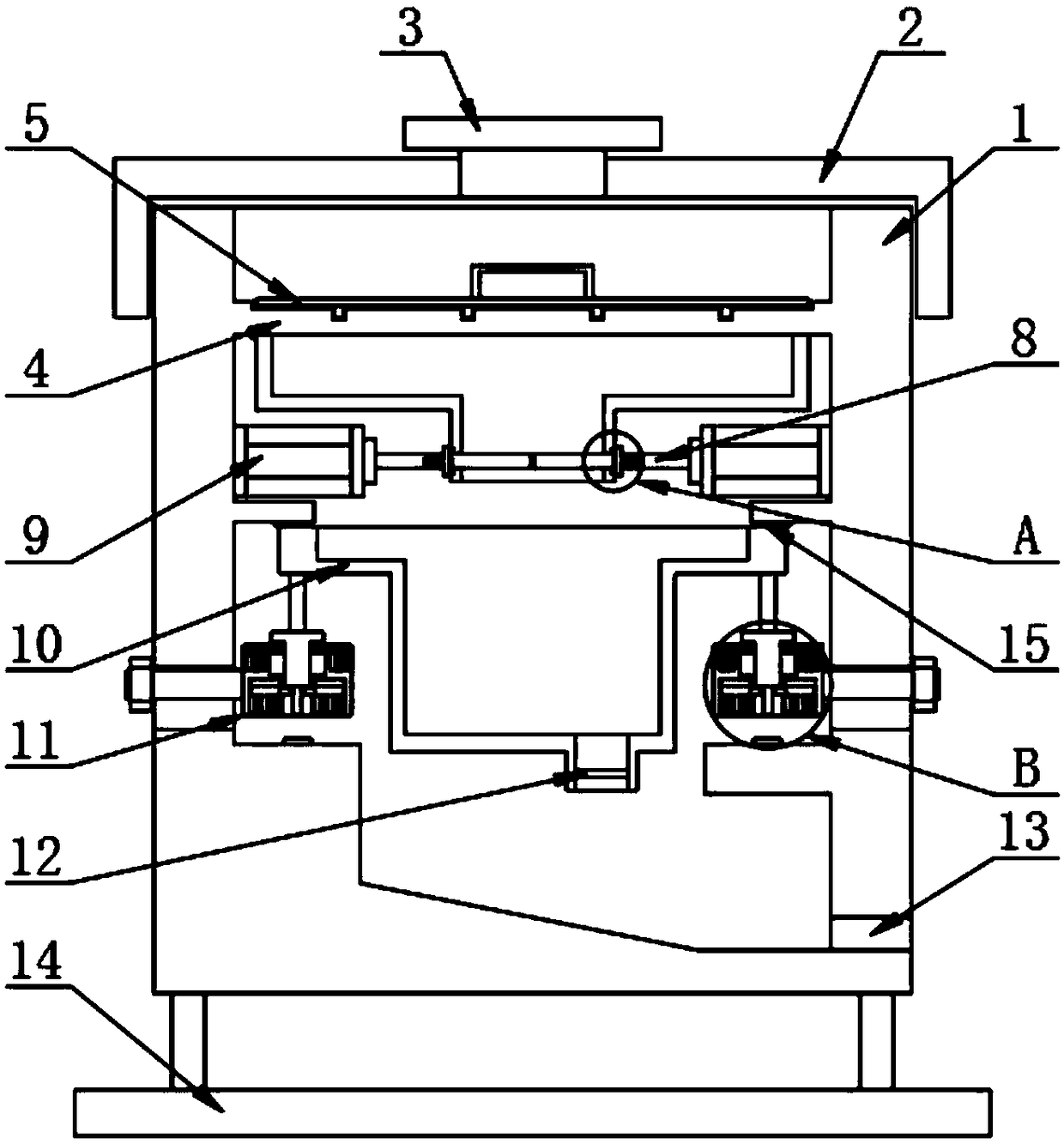

[0024] The present invention provides such Figure 1-5 The shown aquaculture feeding robot includes a housing 1, the top of the housing 1 is provided with a cover plate 2, the top of the cover plate 2 is provided with a feeding port 3, and the inside of the housing 1 is provided with a support rod 4 , the inner side of the pole 4 is provided with a storage compartment 5, the top of the storage compartment 5 is provided with a handle 6, the bottom surface of both sides of the storage compartment 5 is provided with clip strips 7, and both sides of the storage compartment 5 are provided with clips. buckle device 8, the outside of the buckle device 8 is provided with a cylinder 9, the bottom of the buckle device 8 is provided with a weighing bin 10, and the bottom of the weighing bin 10 is provided with a card weighing device 11, and the weighing The bottom surface of the bin 10 is provided with a solenoid valve 12, the bottom of the weighing bin 10 is provided with a discharge po...

Embodiment 2

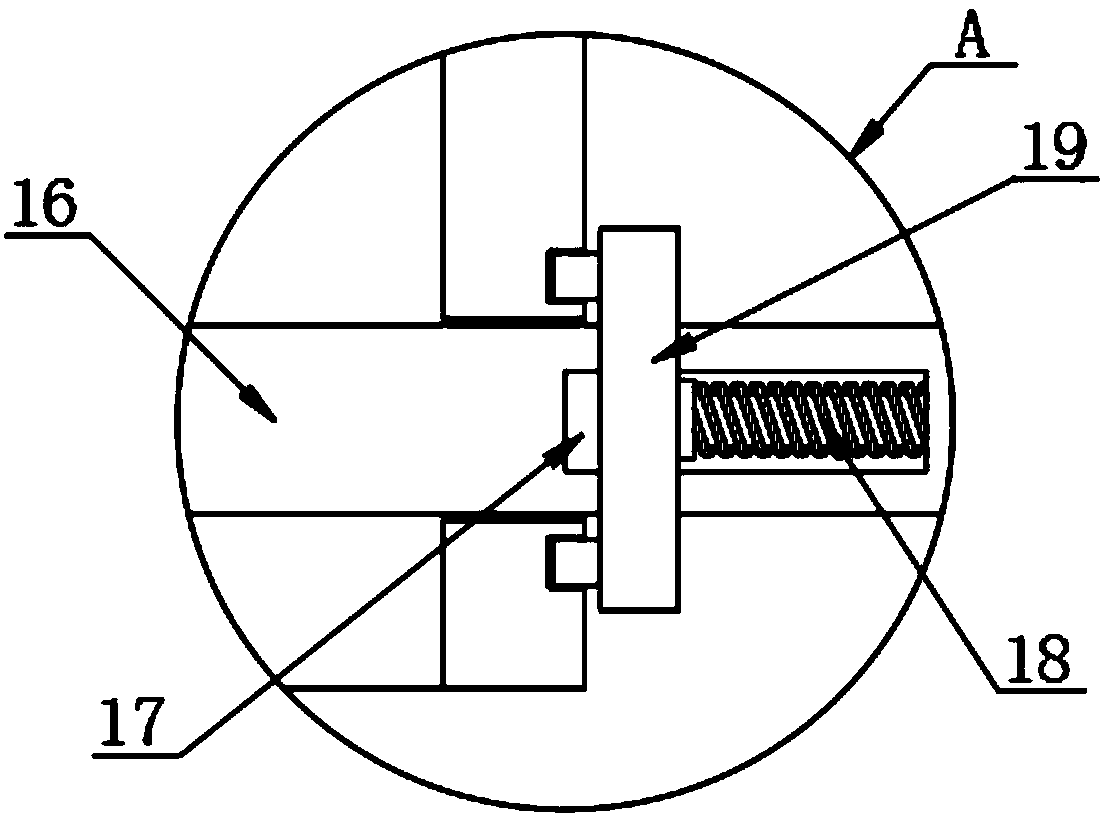

[0027] The buckle device 8 includes a pressure plate 16, the inside of the pressure plate 16 is provided with a chute 17, the inside of the chute 17 is provided with a first spring 18, and the outside of the pressure plate 16 is provided with a fastening plate 19, through which the handle 6 When the storage bin 5 is placed, the storage bin 5 is placed together with the support rod 4 through the clip 7, thereby ensuring the stability of the storage bin 5.

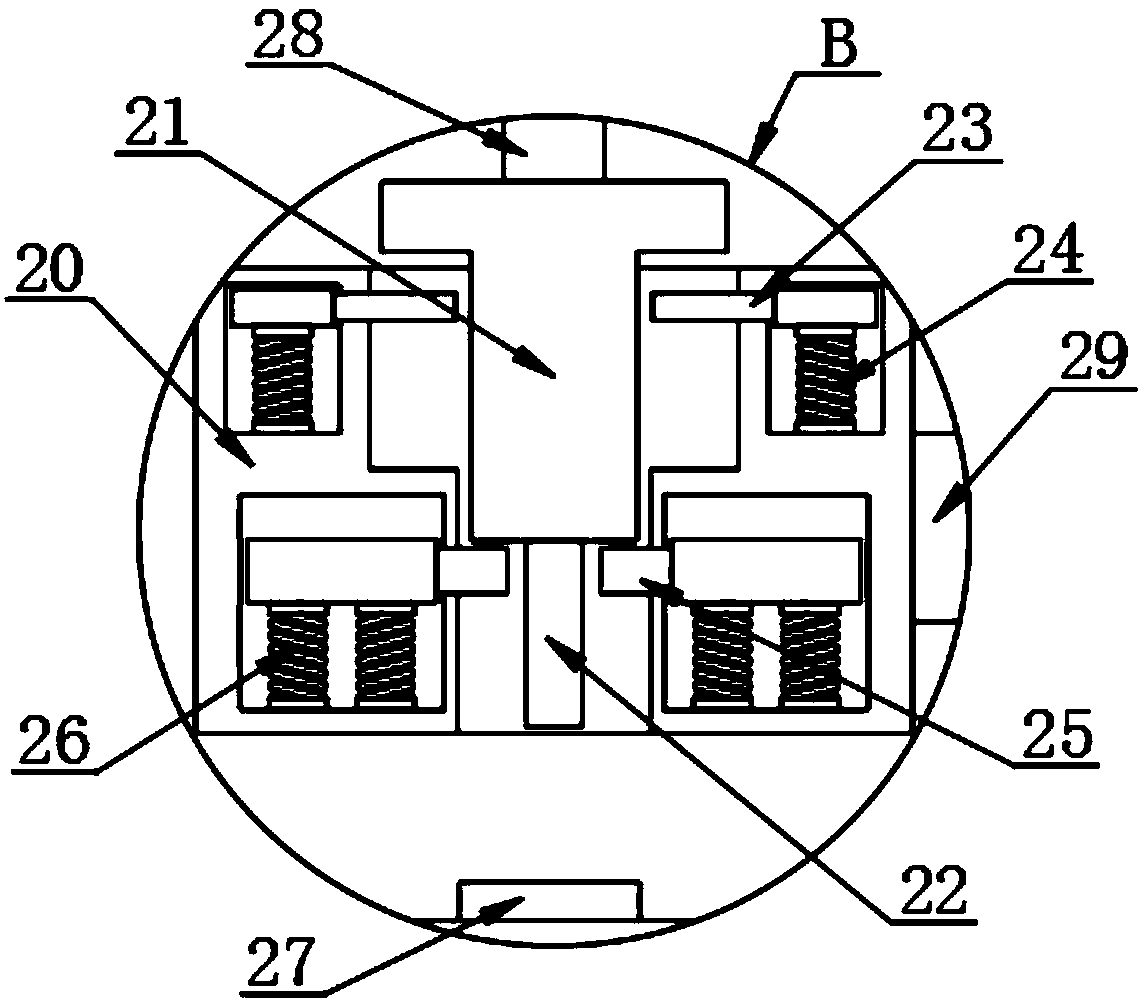

[0028] The card weighing device 11 includes an outer frame 20, the outer frame 20 is provided with a briquetting block 21, and the bottom end of the briquetting block 21 is provided with a connecting rod 22, which is convenient for the connecting rod 22 to come into contact with the pressure sensor 27, thereby controlling Weigh the storage capacity of the silo 10, the bottom of the two sides of the briquetting block 21 is provided with a first mobile frame 23, the bottom of the first mobile frame 23 is provided with a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com