Plaster automatic forming apparatus

An automatic molding and plaster technology, which is applied in the direction of making medicines into special physical or taking forms of devices, other household appliances, household components, etc., can solve waste, the content of effective traditional Chinese medicine powder does not meet the prescribed standards, and plaster sticking is time-consuming. Labor and other problems, to achieve the effect of low purchase and use costs, good consistency of plaster dosage, and improved drug efficacy consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

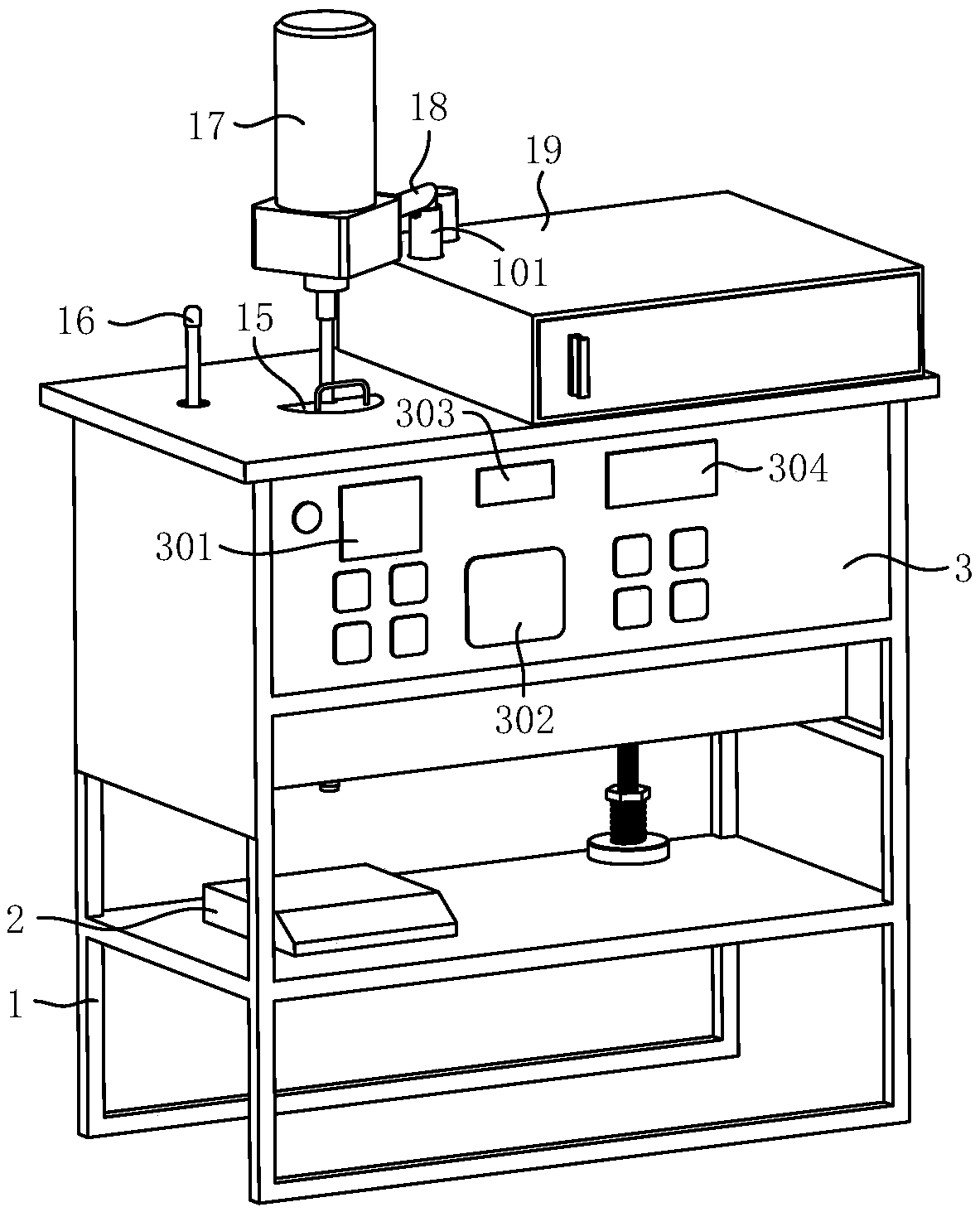

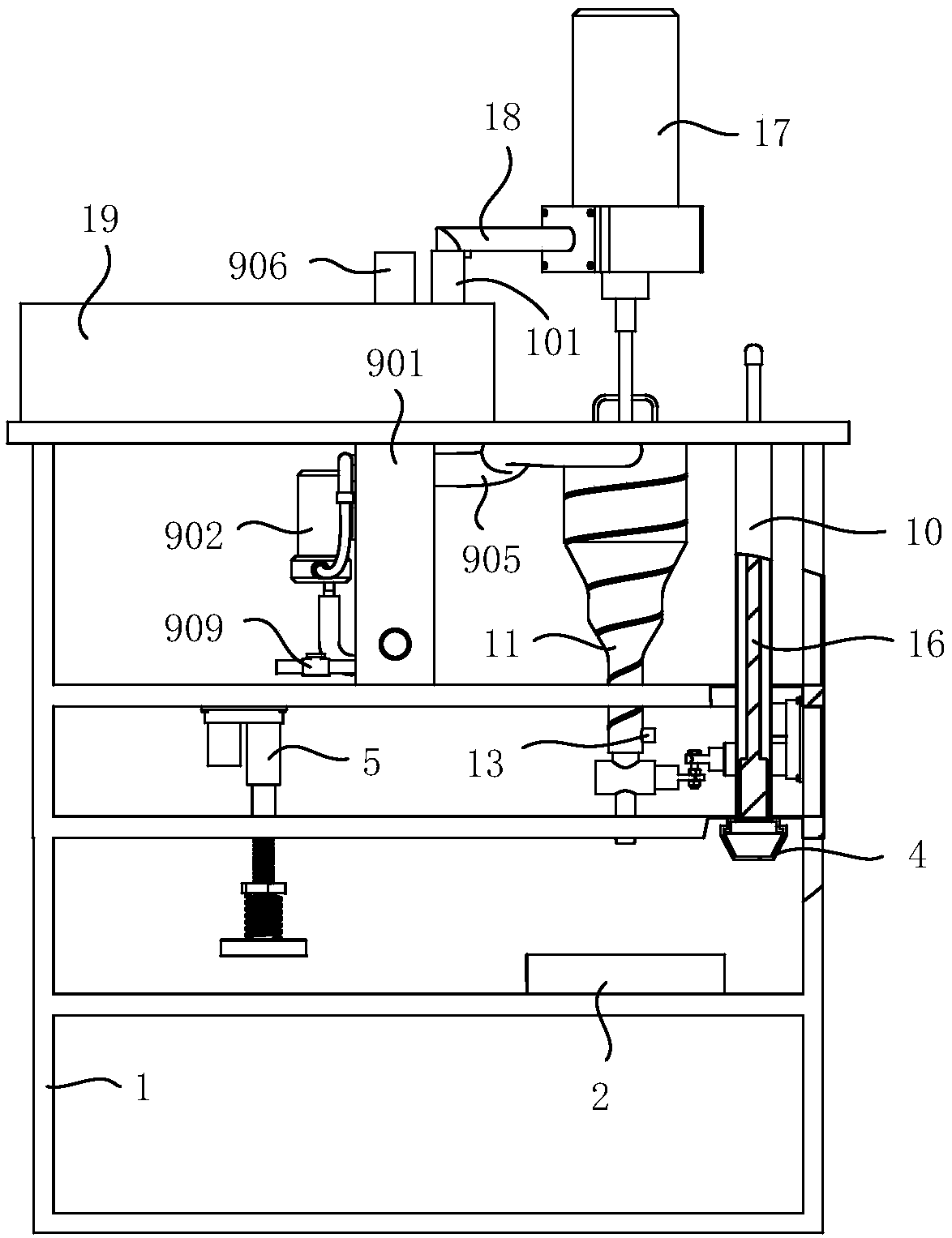

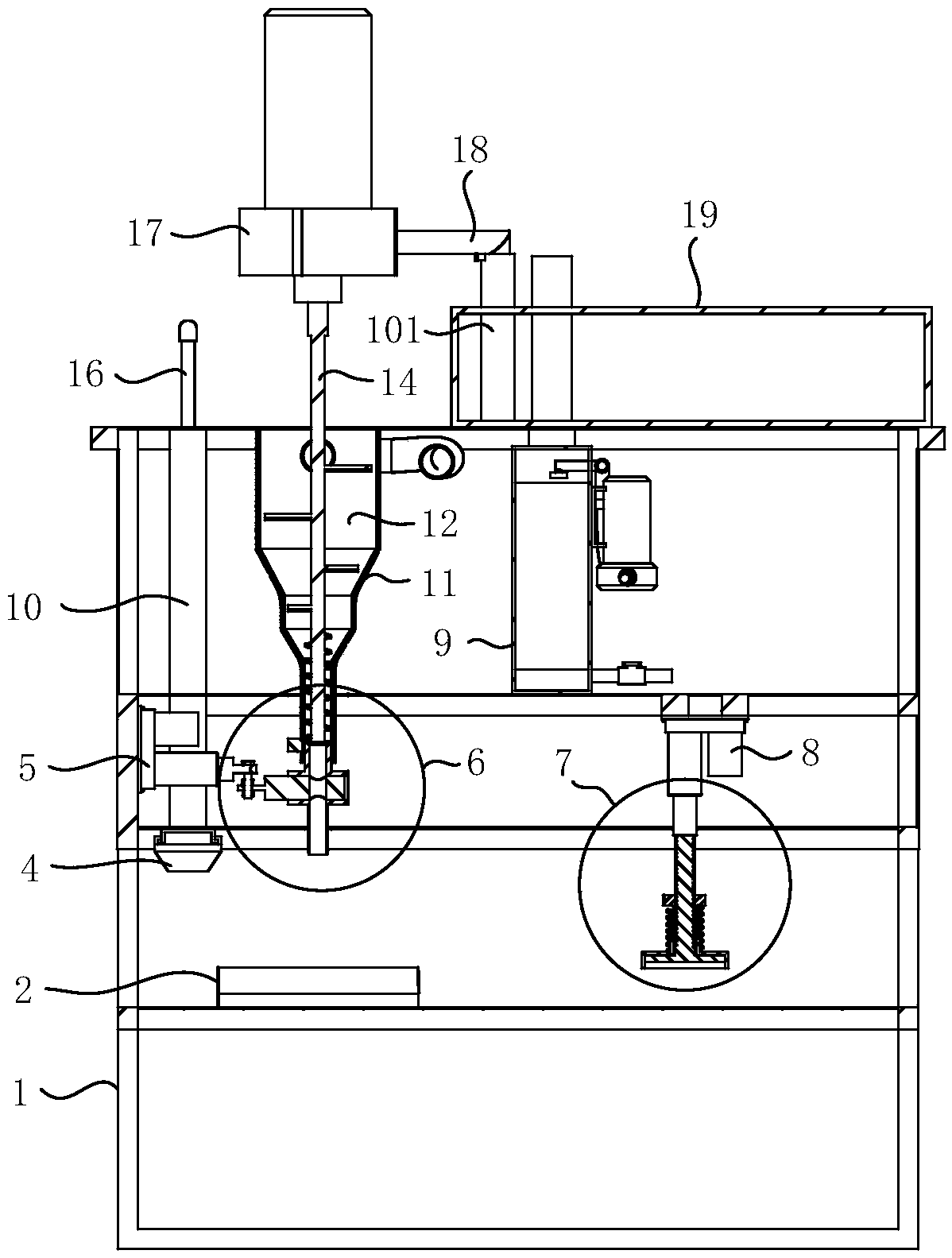

[0032] Such as figure 1 , figure 2 , image 3 As shown, an automatic plaster forming equipment mainly includes a machine base 1, a control cabinet 3, a first electric push rod 5, a valve assembly 6, a heating belt 11, a plaster cylinder 12, a transmission shaft 14, and a reduction motor 17. Wherein the plaster tube 12 is thick at the top and thin at the bottom, and is vertically arranged in the machine base 1. The outer wall of the plaster tube 12 is wound with a heating belt 11, and the top opening of the plaster tube 12 is provided with a plaster tube cover 15, and at the outlet of the plaster tube 12 The feed port is provided with a valve assembly 6 . Described plaster tube 12 central axis places are equipped with transmission shaft 14, as Figure 4 , Figure 5 As shown, the transmission shaft 14 is provided with one or more stirring teeth 1402, and the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com