Efficient composite sterilization device

A kind of sterilization equipment and high-efficiency technology, which is applied in the direction of sanitary equipment for toilets, buildings, water supply devices, etc., can solve the problems of poor sterilization effect, failure to meet sterilization requirements, long sterilization time, etc., and achieve uniform spraying and shorten the time of sterilization. Sterilization time, the effect of improving the sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

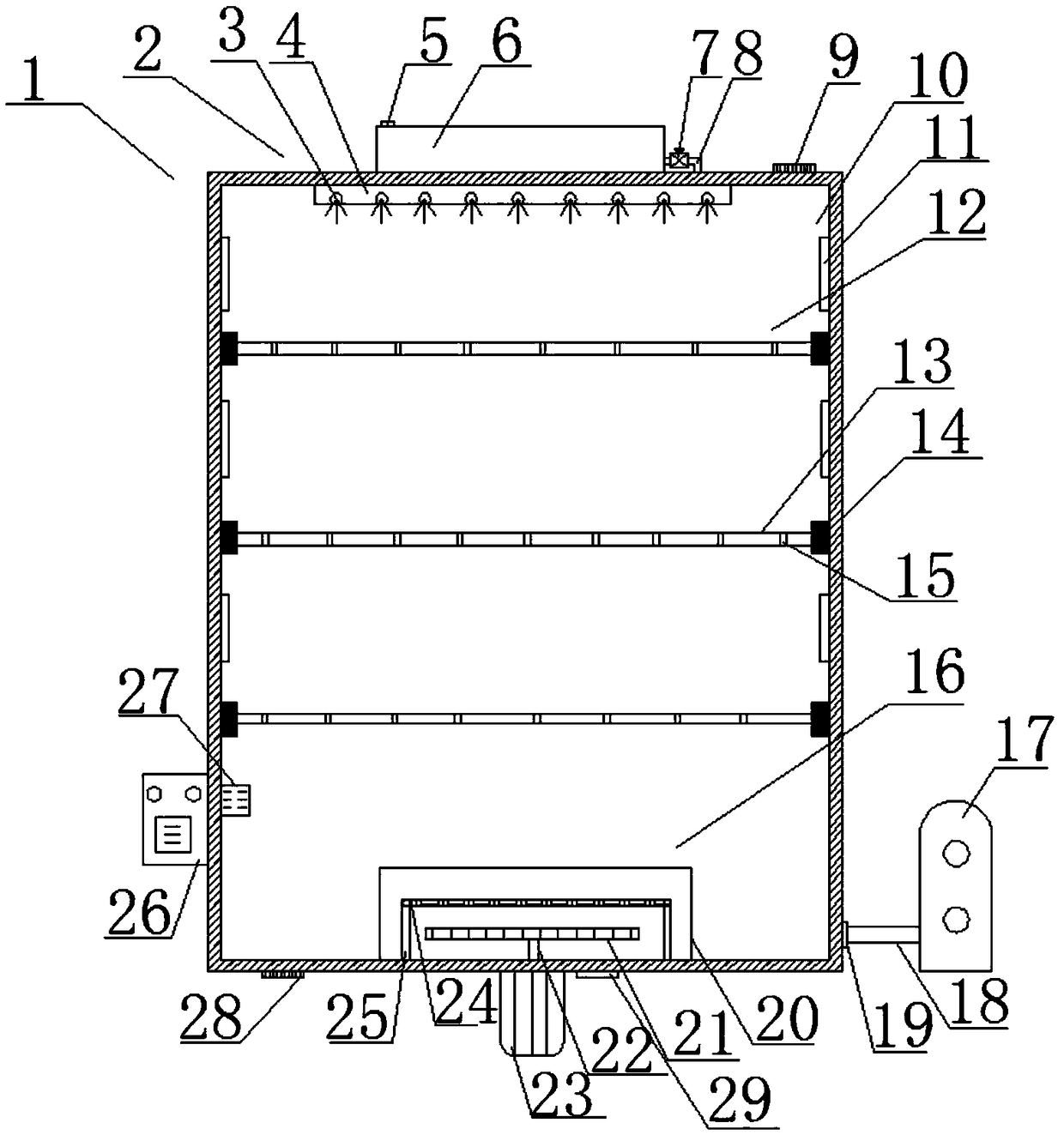

[0033] Such as figure 1 As shown, a high-efficiency composite sterilization equipment includes a sterilizer body 1 and a side door hinged with the sterilizer body 1, and is characterized in that: the top surface of the sterilizer body 1 is provided with an air outlet 9, and the bottom surface is provided with There is a water outlet 28, and the sterilizer body 1 includes a shelf 12, a disinfectant spray device 2, a dry heat sterilizer 16, an ultraviolet sterilizer 10 and an ozone sterilizer 17, and the disinfectant spray device 2 is located at The top surface of the sterilizer body 1, the dry heat sterilization device 16 is located on the bottom surface of the sterilizer body 1, and the bottom surface of the sterilizer body 1 is located at the dry heat sterilization device 16 and is provided with an air inlet 29 , the ultraviolet sterilizing device 10 is fixedly installed on the inner wall of the sterilizer body 1, and the ozone sterilizing device 17 communicates with the ozon...

Embodiment 2

[0038] According to Example 1, such as figure 1 As shown, the disinfectant spraying device 2 includes a liquid storage tank 6 fixedly installed on the outer wall of the top surface of the sterilizer body 1 and a spray pipe 4 located on the inner wall of the top surface of the sterilizer body 1, and the liquid storage tank 6 is provided with There is a liquid exchange port 5, and the liquid storage tank 6 communicates with the spray pipe 4 through a liquid inlet pipe 8, the liquid inlet pipe 8 is provided with a flow valve 7, and a number of nozzles 3 are evenly distributed on the spray pipe 4. The setting of the flow valve 7 can effectively control the spraying amount of the disinfectant, and the setting of the nozzle 3 can make the spraying of the disinfectant more uniform, farther away and wider in scope.

Embodiment 3

[0040] According to Example 1, such as figure 1 As shown, the dry heat sterilization device 16 includes a heating net 24 and a cooling fan 21. The heating net 24 is fixedly connected to the bottom surface of the sterilizer body 1 through a fixing rod 25. The cooling fan 21 is located between the heating net 24 and the bottom surface of the sterilizer body 1. between the bottom surfaces of the sterilizer body 1. The setting of cooling fan 21 can accelerate the circulation of air and speed up the temperature rise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com