Non-stick pan inner coating production line

A production line, non-stick pan technology, applied in spraying devices, spray booths, etc., can solve the problems of wasting space, low production efficiency, long beginning and end of the assembly line, etc., to ensure spraying quality, improve production efficiency, and improve cooling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

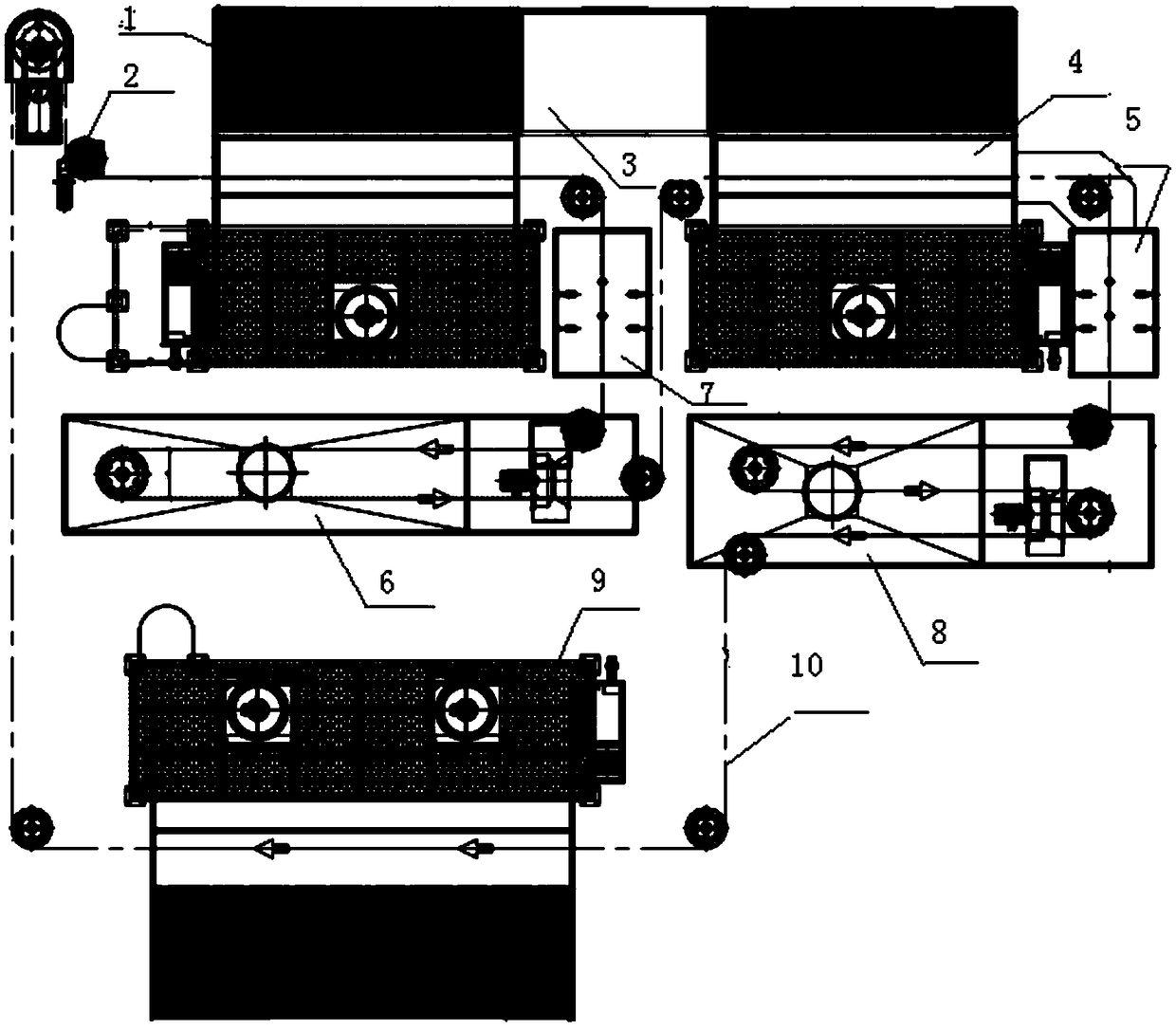

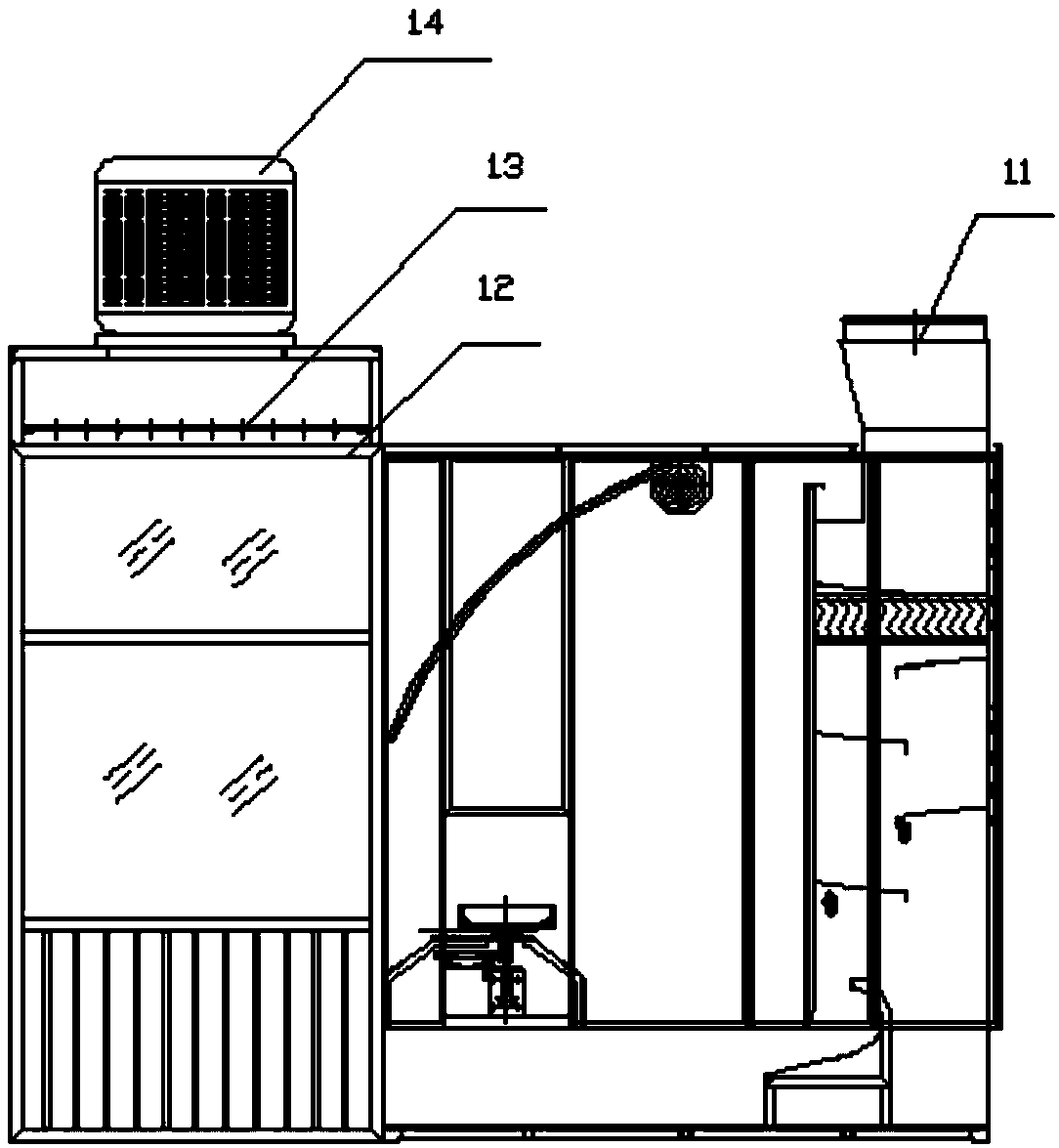

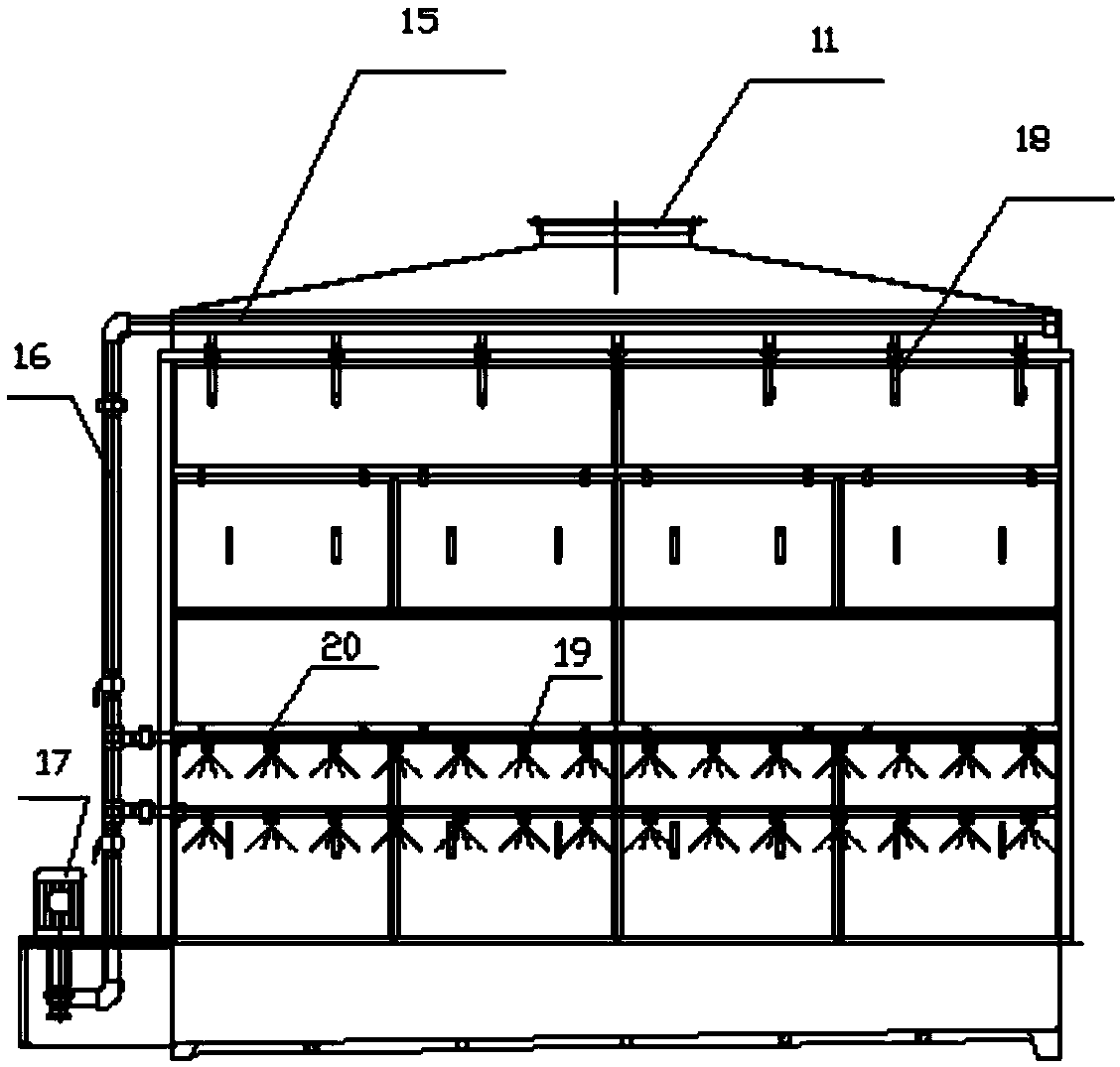

[0015] Non-stick pan internal coating production line, which includes a paint spraying device, a drying device, a cooling device and a circulation chain 10. The paint spraying device includes a paint mixing room 3, a primer spraying room 1, a medium paint spraying room 4 and a topcoat spraying room 9 , the drying device includes a first drying device 7 and a second drying device 5, the cooling device includes a first cooling device 6 and a second cooling device 8, and the primer spray booth and the middle paint spray booth are arranged side by side Set, the paint mixing room is located at the rear between the primer spray booth and the intermediate paint spray booth, the first drying device is located at the front between the primer spray booth and the intermediate paint spray booth, and the first The cooling device is located in front of the primer spray booth and the first drying device, the second drying device is located on the right side of the intermediate paint spray boo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com