Frequency-changing water supply method for hot continuous line rolling and ultra-fast cooling system

An ultra-fast cold and hot continuous rolling technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve problems affecting equipment and system stability, pipeline vibration, unfavorable temperature control, etc., to achieve long-term guarantee The effect of continuous and stable operation, reducing pipeline impact and reducing pipeline vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment takes the production of Q235B steel with a thickness of 6 mm as an example.

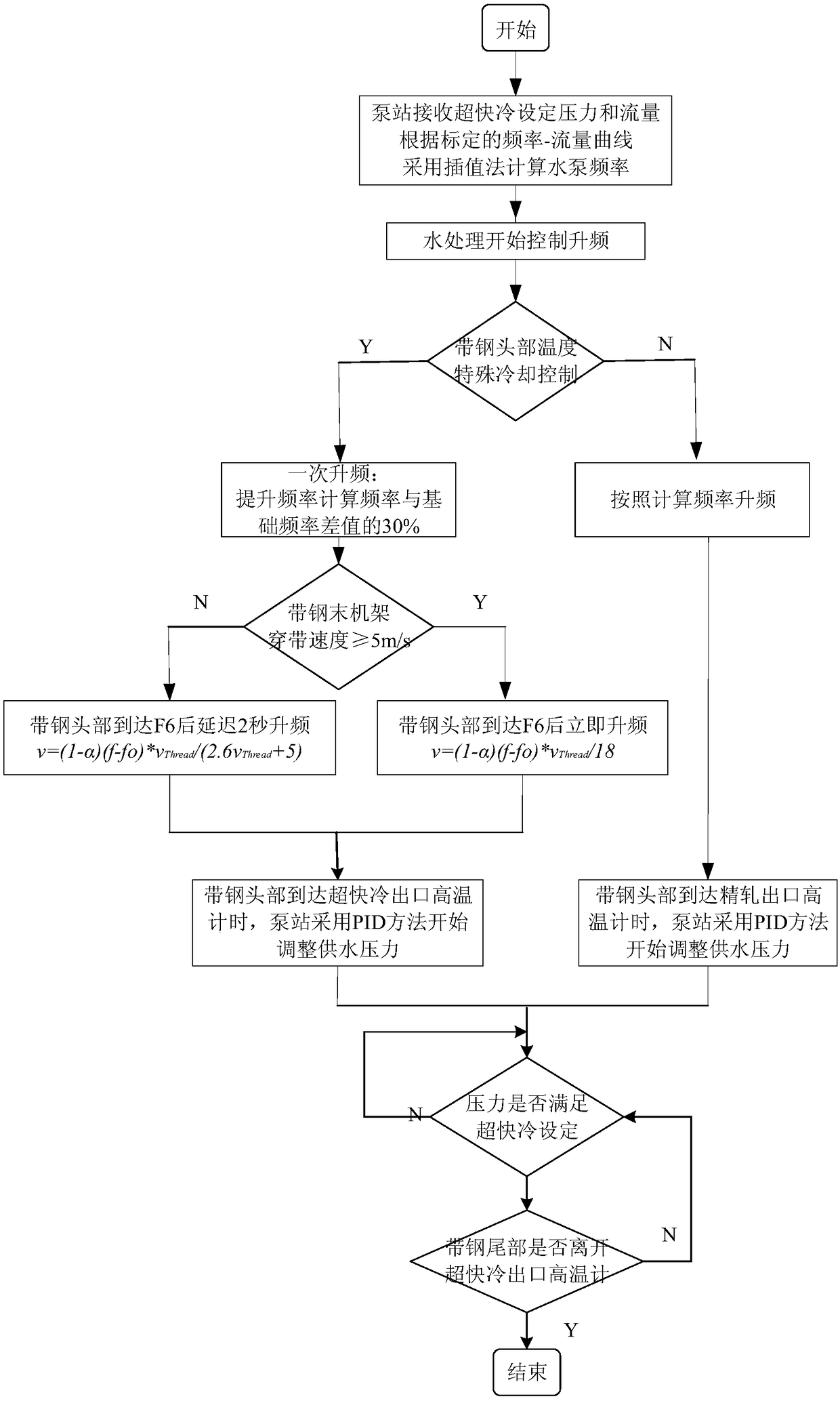

[0029] A frequency conversion water supply method for the ultra-fast cooling system of a hot continuous rolling line, the program flow chart is shown in figure 1 , including the following steps:

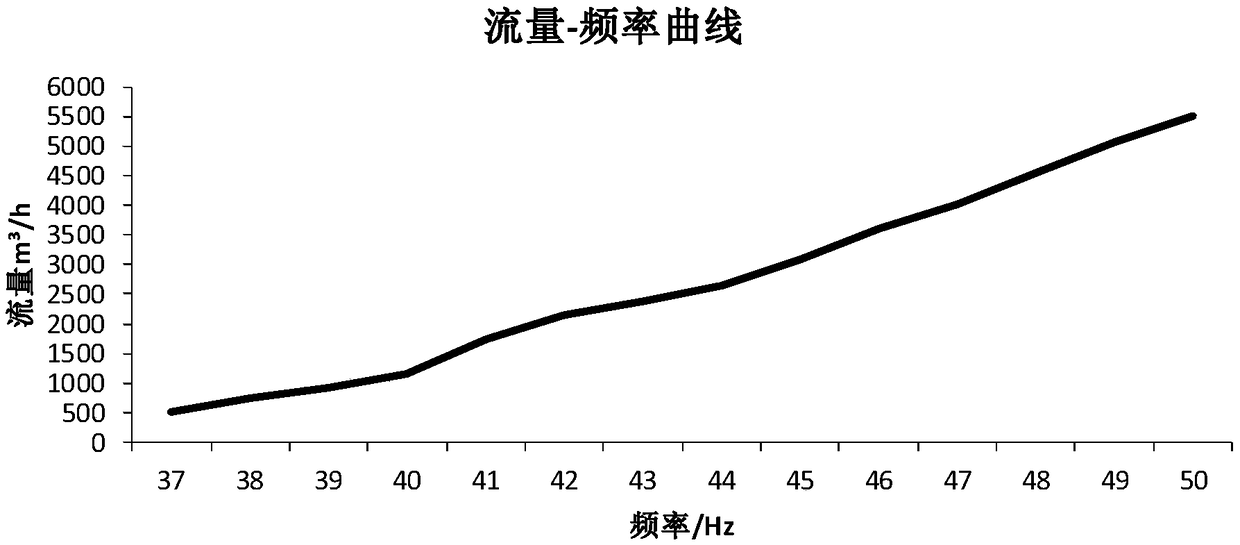

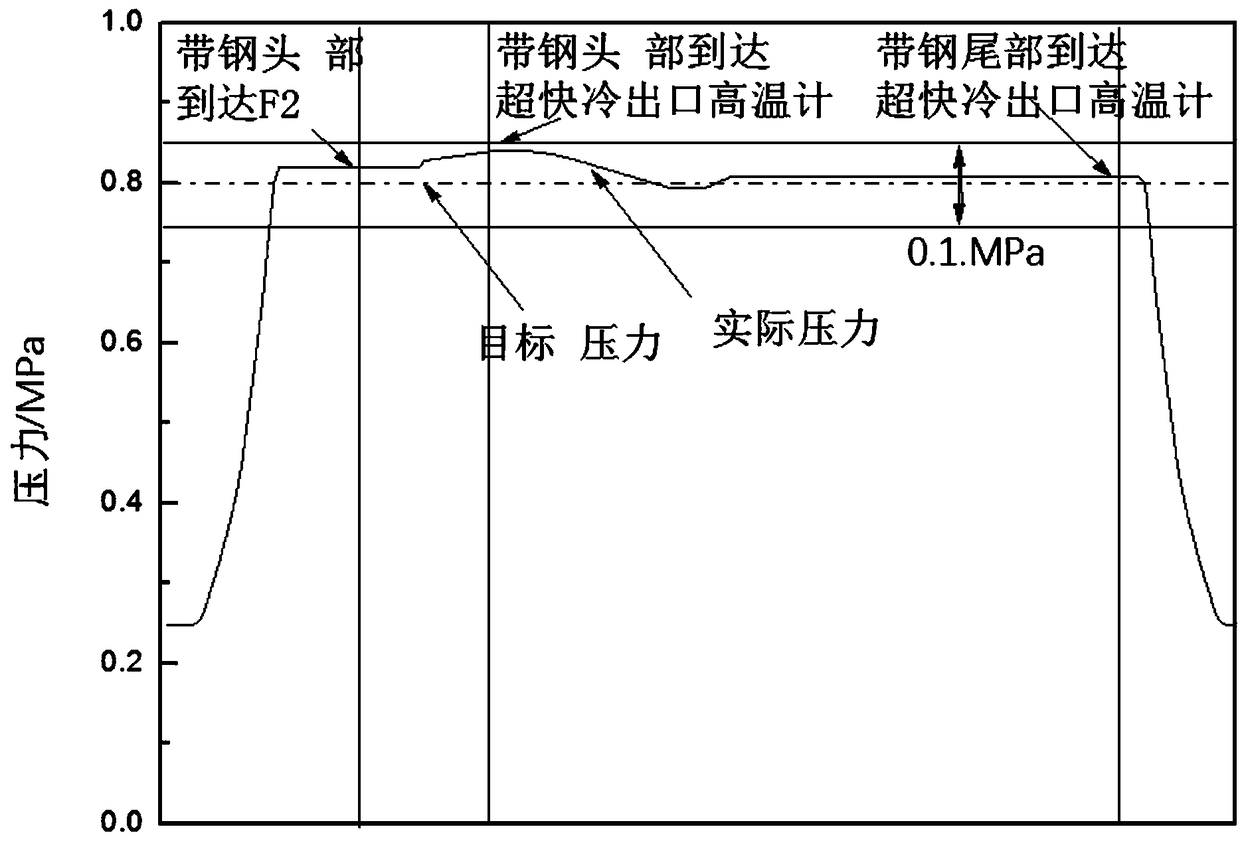

[0030] Step 1: When the head of the strip steel reaches the pump frequency speed-up point, finish rolling F1 bite steel, as the water pump frequency speed-up point, set the pressure of the ultra-fast cooling system at this time to 0.8MPa and the flow rate to 2200m 3 / h is transmitted to the pumping station, and the pumping station uses the interpolation method to calculate the pump frequency according to the ultra-fast cold water pressure, flow rate and the calibrated pump frequency-flow curve, and the calculated pump frequency is 42Hz.

[0031] Among them, the calibration method of the pump frequency-flow curve is as follows: Before calibration, all the pressure relief valves of the...

Embodiment 2

[0036] In this embodiment, the production of 11mm Q345B is taken as an example.

[0037] A frequency conversion water supply method for the ultra-fast cooling system of a hot continuous rolling line, the program flow chart is shown in figure 1 , including the following steps:

[0038] Step 1: When the head of the strip steel reaches the pump frequency speed-up point F1 and bites the steel, as the water pump frequency speed-up point, set the pressure of the ultra-fast cooling system at this time to 0.8MPa and the flow rate to 4500m 3 / h is transmitted to the pumping station, and the pumping station calculates the pump frequency by interpolation method according to the ultra-fast cold water pressure, flow rate and the calibrated pump frequency-flow curve, and the calculated pump frequency is 48Hz.

[0039]Among them, the calibration method of the pump frequency-flow curve is as follows: Before calibration, all the pressure relief valves of the ultra-fast cooling diversion heade...

Embodiment 3

[0049] This embodiment takes the production of 22mm X70 pipeline steel as an example.

[0050] A frequency conversion water supply method for the ultra-fast cooling system of a hot continuous rolling line, the program flow chart is shown in figure 1 , including the following steps:

[0051] Step 1: When the head of the strip steel reaches the pump frequency speed-up point F1 and bites the steel, as the water pump frequency speed-up point, set the pressure of the ultra-fast cooling system at this time to 0.8MPa and the flow rate to 5500m 3 / h is transmitted to the pumping station, and the pumping station uses the interpolation method to calculate the pump frequency according to the ultra-fast cold water pressure, flow rate and the calibrated pump frequency-flow curve, and the calculated pump frequency is 50Hz.

[0052] Among them, the calibration method of the pump frequency-flow curve is as follows: Before calibration, all the pressure relief valves of the ultra-fast cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com