Investment casting mold shell dewaxing device and investment casting mold shell dewaxing method

A technology of investment casting and mold shell, which is applied in the field of investment casting mold shell dewaxing device, which can solve the problems of support plate running out of fire, mold shell cracking, casting inclusions, etc., so as to speed up the dewaxing speed and prolong the service life The effect of increasing the lifespan and the frequency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

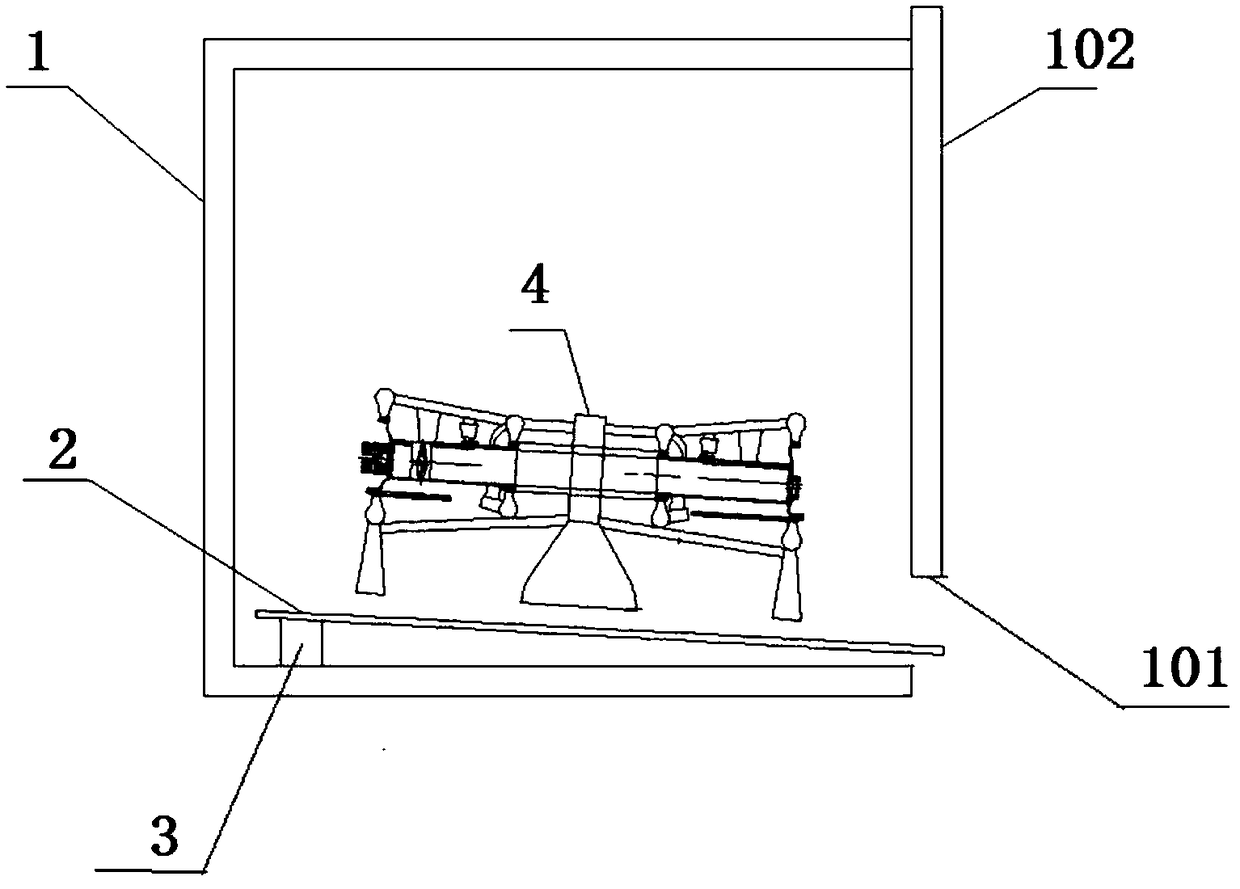

[0024] Such as figure 1 As shown, the present invention provides an investment casting mold shell dewaxing device and an investment casting mold shell dewaxing method, including a trolley furnace 1 and a dewaxing plate 2, and a dewaxing port 101 is arranged on the outer surface of the trolley furnace 1 , The dewaxing tray 2 is placed obliquely inside the trolley furnace 1, and the lower end of the dewaxing tray 2 relative to the bottom of the trolley furnace 1 protrudes from the dewaxing port 101.

[0025] By adopting the technical solution of the present invention, during the process of heating the mold shell to remove wax, the furnace door is hidden, which is convenient for the operator to observe, and the heating temperature can be adjusted as required to speed up the dewaxing speed, and the melted wax It is discharged in time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com