Special rotary disc structure for liquid-by-liquid drop centrifugal atomization method

A technology of centrifugal atomization and turntable, which is applied in the field of preparation of ultra-fine spherical particles, which can solve problems affecting atomization efficiency, poor wettability, and small adhesion, so as to improve efficiency and quality, ensure safety, and ensure stability Effects on sex and safety

Inactive Publication Date: 2019-01-11

DALIAN UNIV OF TECH +1

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The receiving device of traditional centrifugal atomization mainly uses an integrated turntable structure, and the turntable is usually made of a material with poor wettability with the atomized alloy. At this time, the adhesion between the molten alloy and the surface of the turntable is small, which leads to The kinetic energy of the turntable to conduct the molten liquid film is very limited, and when the temperature and rotation speed of the melt are too high, the melt is prone to slipping, which seriously affects the atomization efficiency

[0003] In view of the poor atomization effect caused by the discomfort of the turntable structure in the traditional centrifugal atomization, it is necessary to redesign a turntable structure to solve the above problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

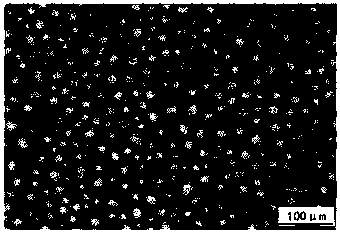

[0043] Such as image 3 As shown, the turntable structure of the present invention is applied to a low-melting pressure rod pulse micro-hole injection device to prepare Sn63Pb37 alloy metal powder,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Login to View More

Abstract

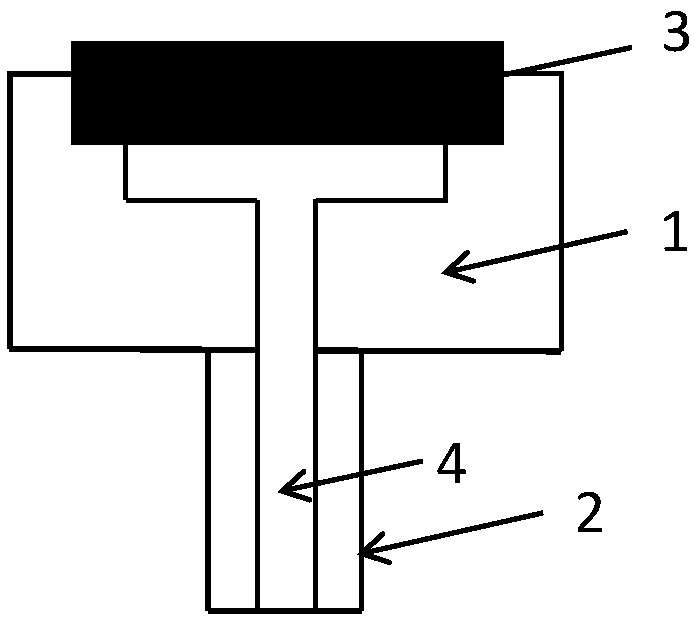

The invention provides a special rotary disc structure for a liquid-by-liquid drop centrifugal atomization method. The special rotary disc structure is characterized by comprising a base body, an atomizing plane and vent holes, wherein the base body is a main body structure with a T-shaped longitudinal section, and the main body structure is composed of a bearing and connecting part at the upper part and a supporting part at the lower part, the upper surface of the bearing and connecting part is provided with a circular groove which is coaxial with a circle center of the bearing and connectingpart and the circular groove has a certain radius; the atomizing plane is of a disc structure, the disc structure cooperates with the circular groove and is in interference fit with the circular groove, and the atomization plane is made of a material with the wettability angle of an atomization melt smaller than 90 degrees; the vent holes are formed in the bearing and connecting part and the supporting part in a penetrating mode, the upper end faces of the vent holes are in contact with the lower end face of the atomizing plane, and the lower ends of the vent holes communicate with the outside. According to the structure, a split type rotary disc structure is mainly adopted, the material with good wettability with the atomized melt is used as the atomization plane of the rotary disc, a material which is poor in thermal conductivity is used as a base body of the rotary disc, so that the metal liquid drops can be well received in an atomizing and pulverizing process, and the spreading atomization of the liquid drop is facilitated.

Description

technical field [0001] The invention belongs to the technical field of preparation of ultrafine spherical microparticles, and in particular relates to a special turntable structure for a droplet-by-drop centrifugal atomization method. Background technique [0002] The receiving device of traditional centrifugal atomization mainly uses an integrated turntable structure, and the turntable is usually made of a material with poor wettability with the atomized alloy. At this time, the adhesion between the molten alloy and the surface of the turntable is small, which leads to The kinetic energy of the turntable to conduct the molten liquid film is very limited, and when the temperature and rotation speed of the melt are too high, the melt is prone to slipping, which seriously affects the atomization efficiency. [0003] In view of the poor atomization effect caused by the discomfort of the turntable structure in the traditional centrifugal atomization, it is necessary to redesign ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22F9/10

CPCB22F9/10Y02P10/25

Inventor 董伟孟瑶朱胜王晓明赵阳许富民白兆丰王延洋韩阳李国斌石晶韩国峰王思捷常青任志强滕涛

Owner DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com