Battery module laser welding quality evaluation method and device

A technology of laser welding quality and battery module, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of automatic evaluation, no battery module laser welding quality, etc., and achieve the effect of accurate evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

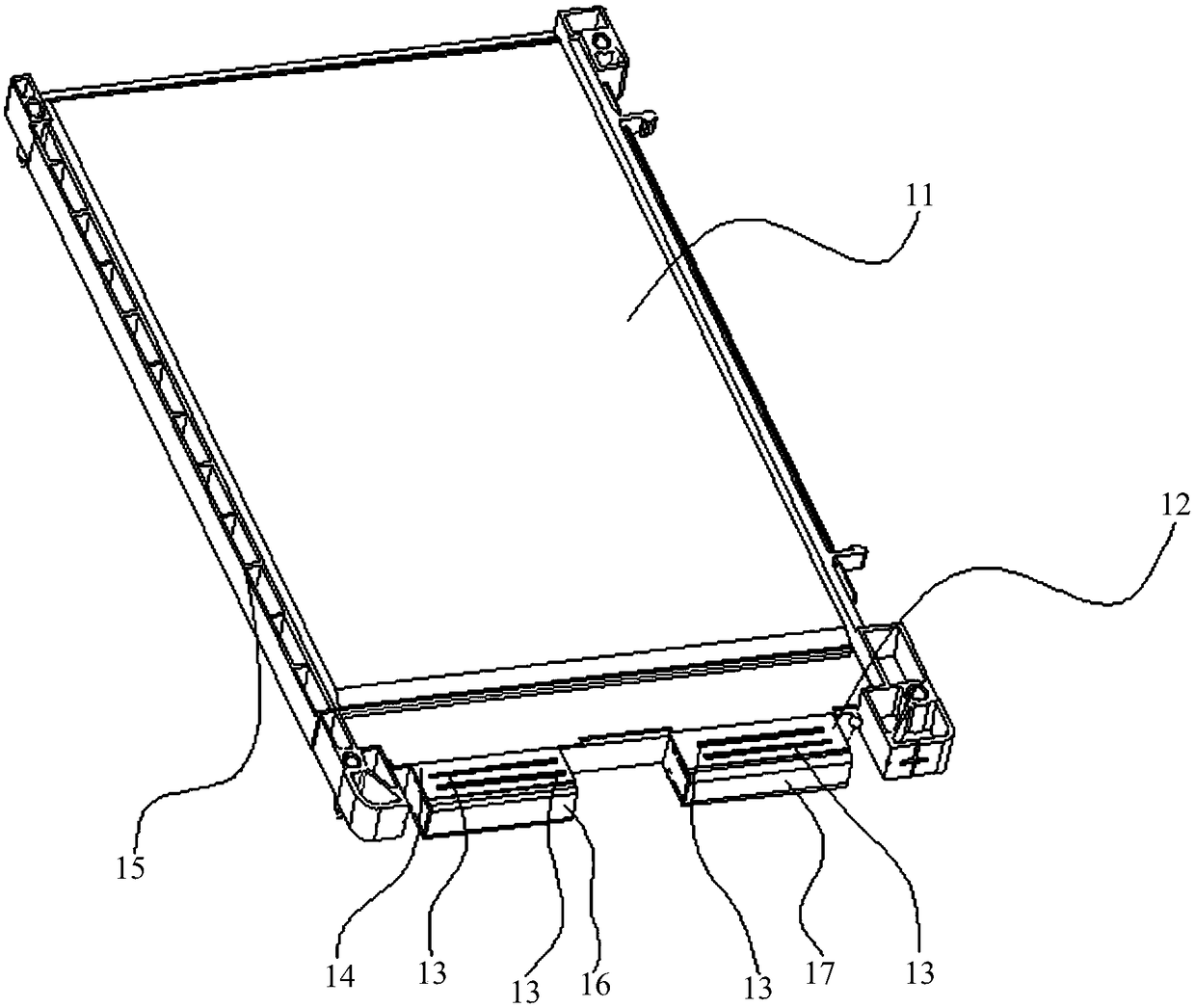

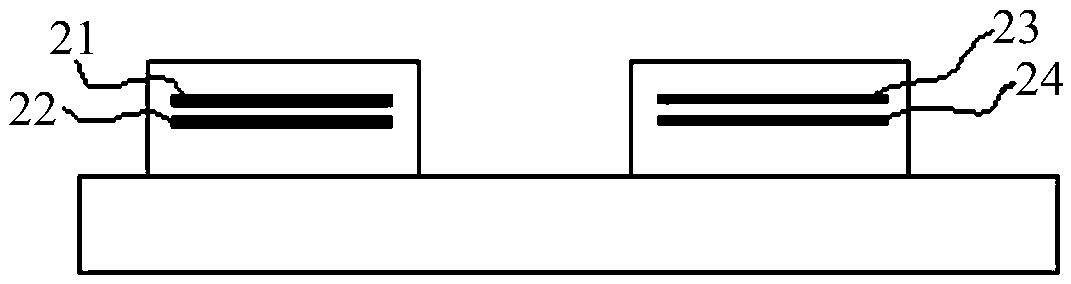

Image

Examples

Embodiment Construction

[0048] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific implementation of the invention will now be described with reference to the accompanying drawings.

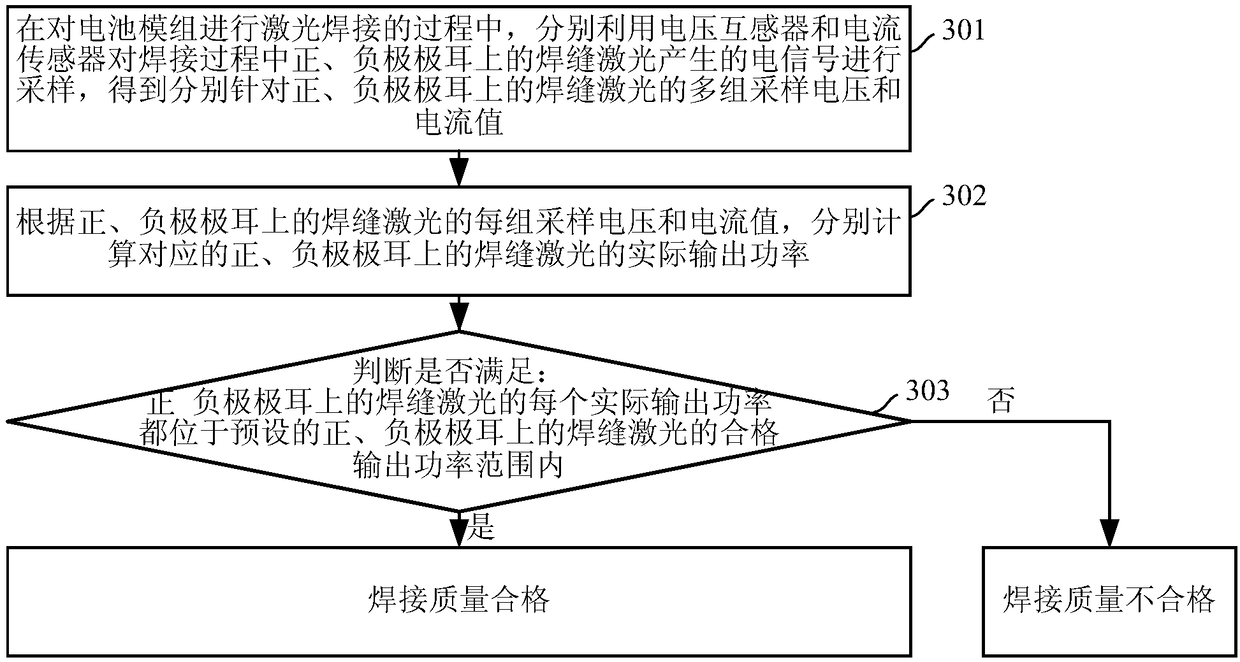

[0049] image 3 It is a flowchart of a battery module laser welding quality assessment method provided by an embodiment of the present invention, and its specific steps are as follows:

[0050] Step 301: In the process of laser welding the battery module, use the voltage transformer and the current sensor to sample the electrical signals generated by the welding seam laser on the positive and negative tabs during the welding process, and obtain the electrical signals for the positive and negative electrodes respectively Multiple sets of sampled voltage and current values of the welding seam laser on the ear.

[0051] Step 302: According to each set of sampled voltage and current values of the welding seam laser on the positive and negative tabs, re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com