Robot assembly line for intelligent production of electronic products

A technology of electronic products and robots, applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems of high input cost, high equipment cost, large area, etc., to achieve smooth production operation, small area, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

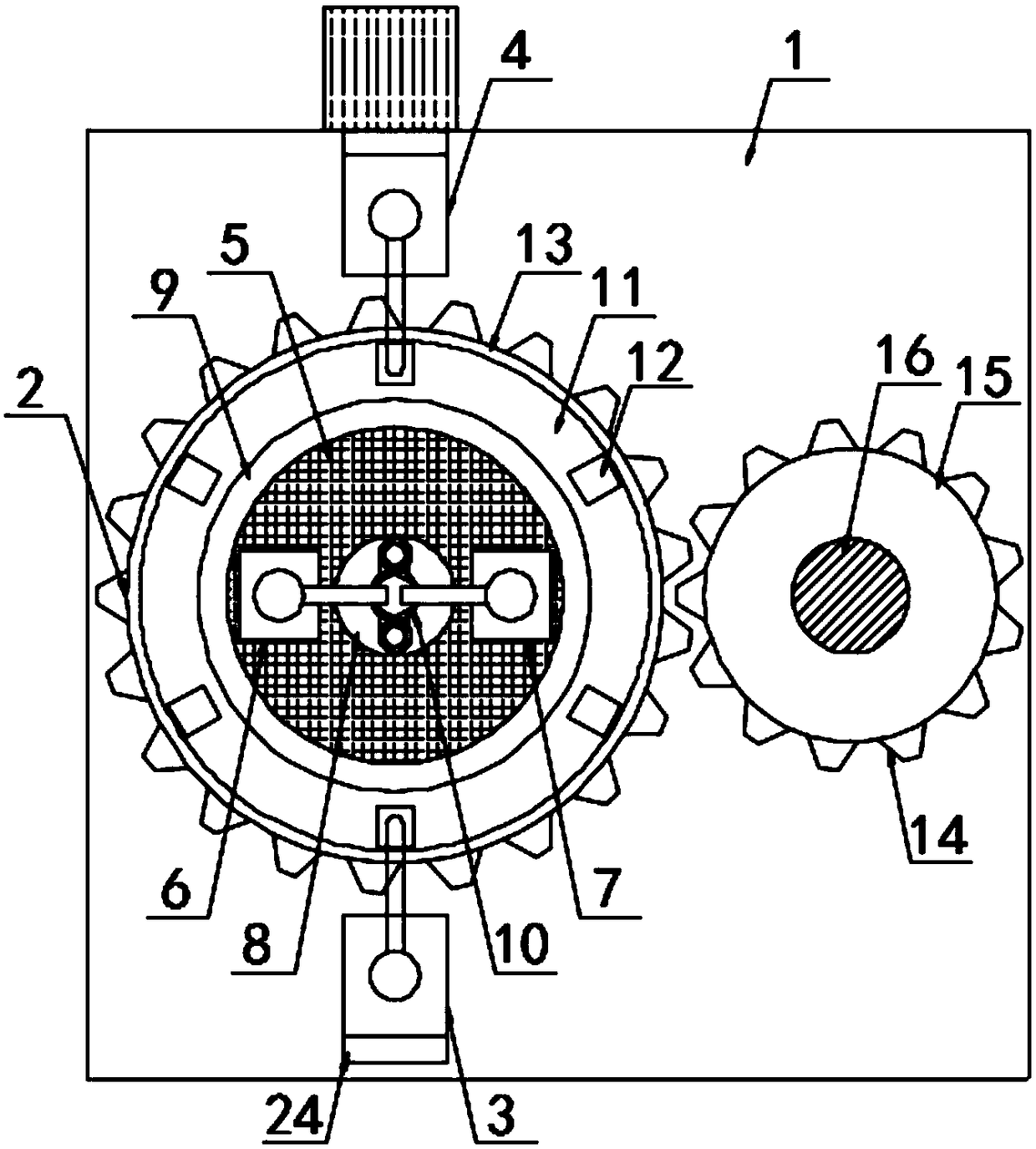

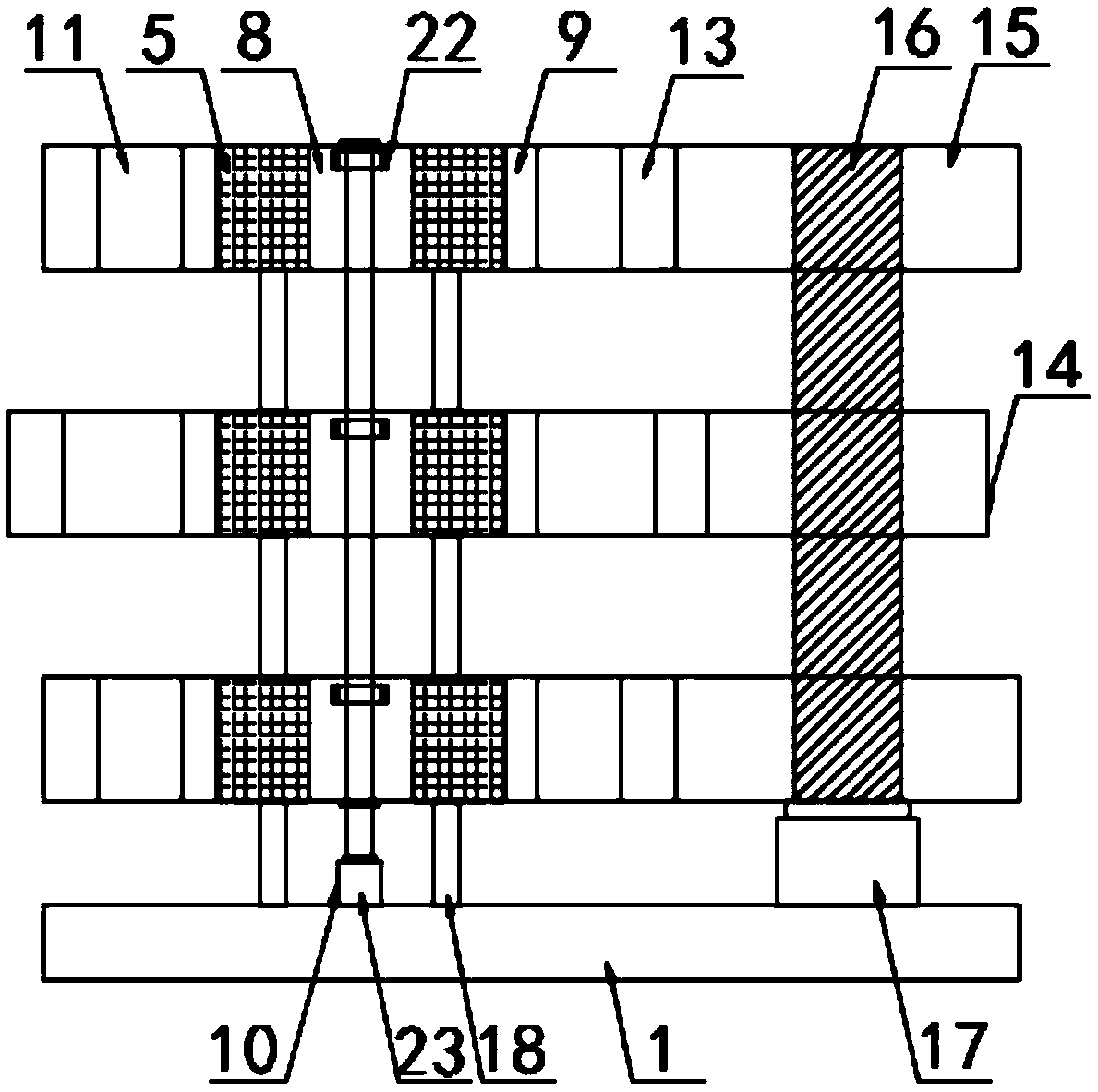

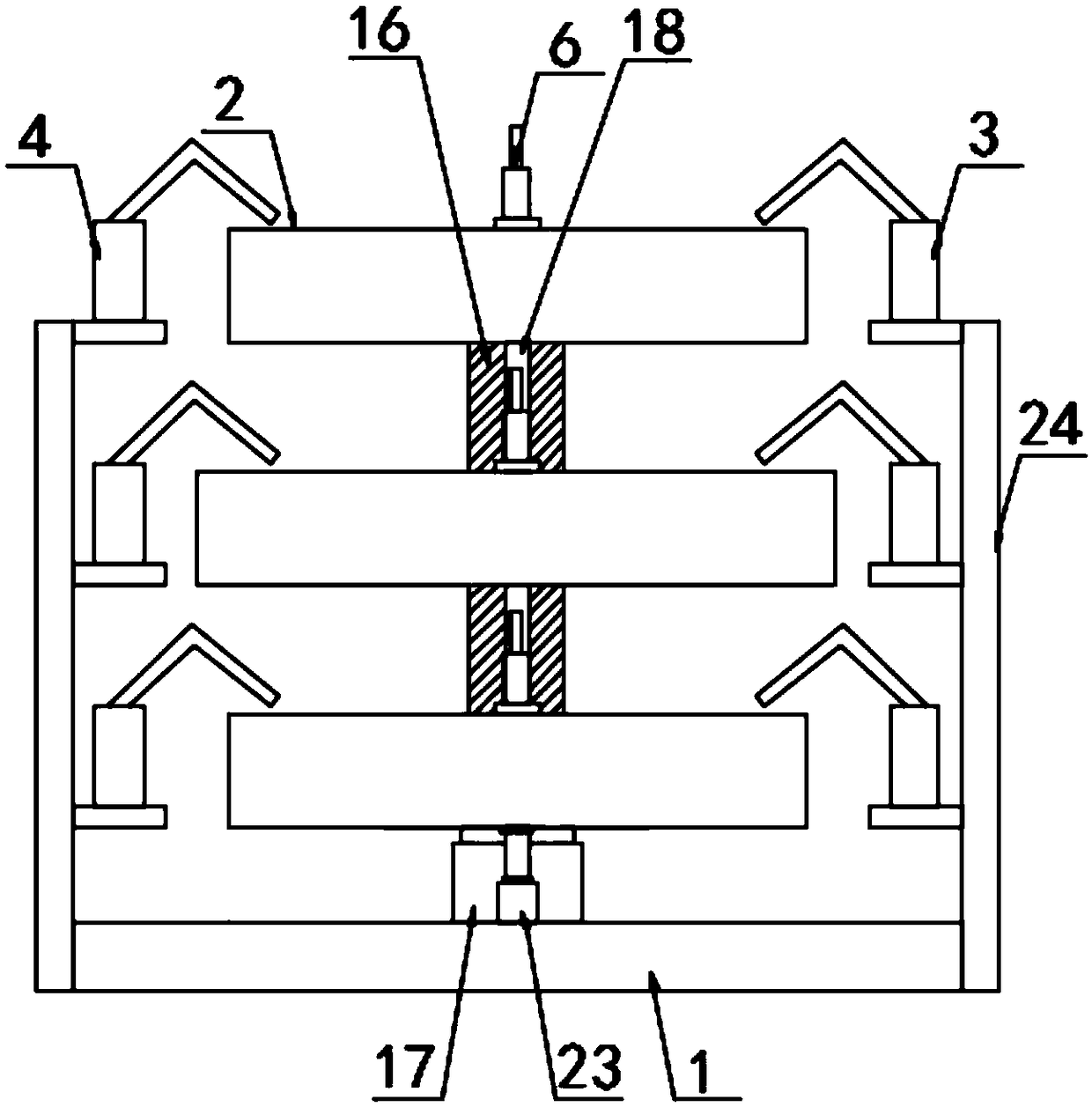

[0024] according to Figure 1-3 The shown robot assembly line for the intelligent production of electronic products includes a workbench 1, an operation platform 2 is provided on the top of the workbench 1, an assembly robot 3 is provided on the front side of the operation platform 2, and an assembly robot 3 is provided on the rear side. A feeding robot 4, the rear side of the feeding robot 4 is provided with a plurality of conveyor belts, which is convenient for feeding materials, and a PLC controller is provided on one side of the workbench 1 to intelligently control the operation of the entire device. The operation table 2 includes Axis 5, one side of the top of the axis 5 is provided with a cleaning robot 6 and the other side is provided with a blanking robot 7, the inside of the axis 5 is provided with a sliding groove 8 and the outside is provided with a ball bearing 9, the sliding A vertical feeding mechanism 10 is provided inside the groove 8, and a conveying rotating ...

Embodiment 3

[0030] Different from Embodiment 1 and Embodiment 2, the size and the number of teeth of the driving gear 15 and the driven gear 13 are adjustable, and can be set according to the number of assembled parts, so that the rotation speed of the operation platform 2 of each layer can be adjusted, and the rotation speed of each layer can be realized. The structure is assembled at the same time, which is convenient for the coordinated work of the whole device, and the processing is efficient.

[0031] The working principle of the present invention:

[0032] Refer to the attached Figure 1-3, when in use, first the top console 2 works first, the conveyor belt transports the parts of small structures to the console 2, the servo motor 17 works to drive the rotating shaft 16 and the driving gear 15 to rotate, and the driving gear 15 drives the driven gear 13 to rotate , so as to drive the conveying rotating plate 11 to rotate, when the conveying rotating plate 11 rotates, the feeding ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com