Spherical vector nozzle device adopting dual hydraulic symmetrical system

A symmetrical system and dual-hydraulic technology, applied in transportation and packaging, ship propulsion, ship parts, etc., can solve the problems of limited adjustment ability, large energy loss, complex mechanical mechanism, etc., and achieve reliable direction control, fast adjustment speed, and adjustment high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

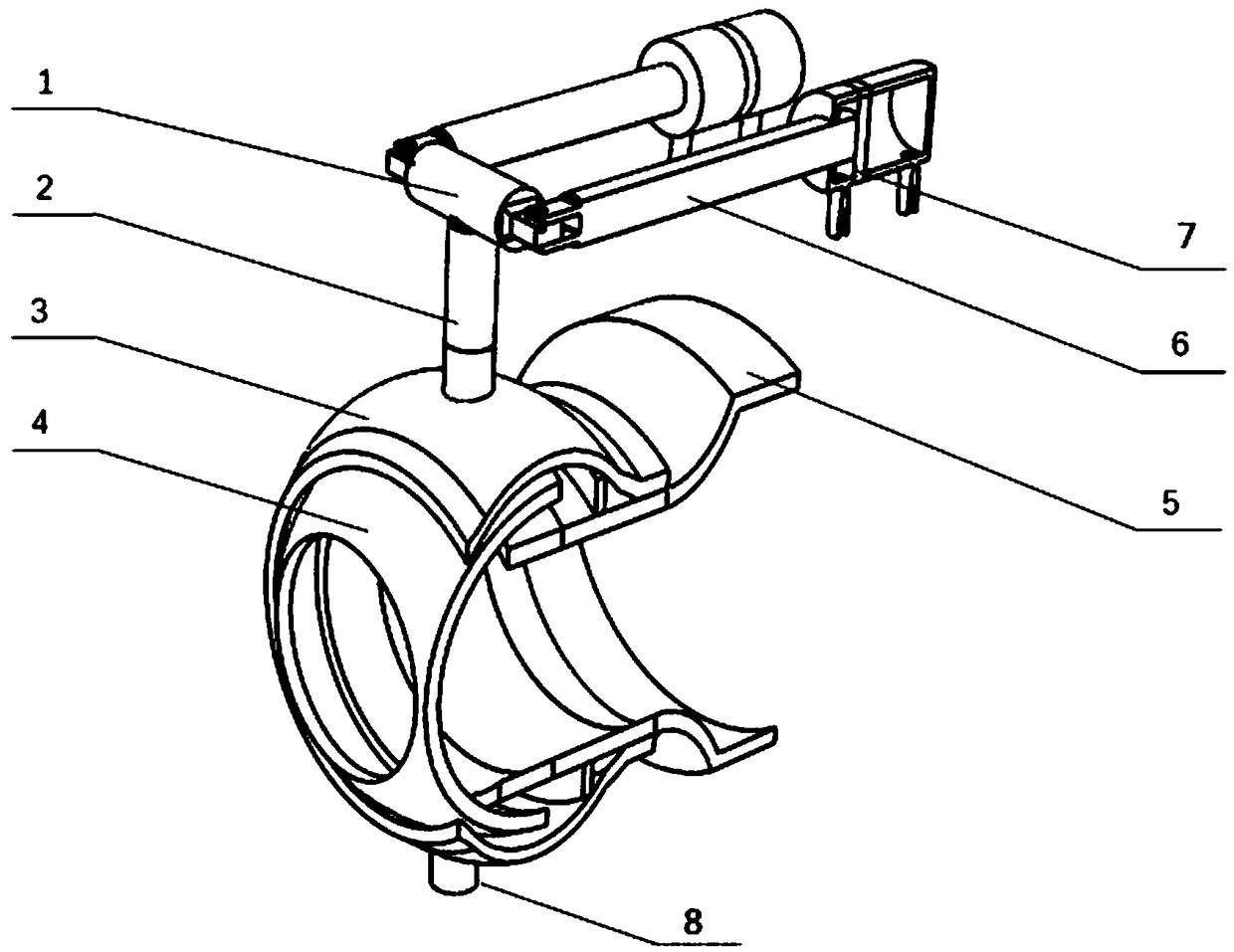

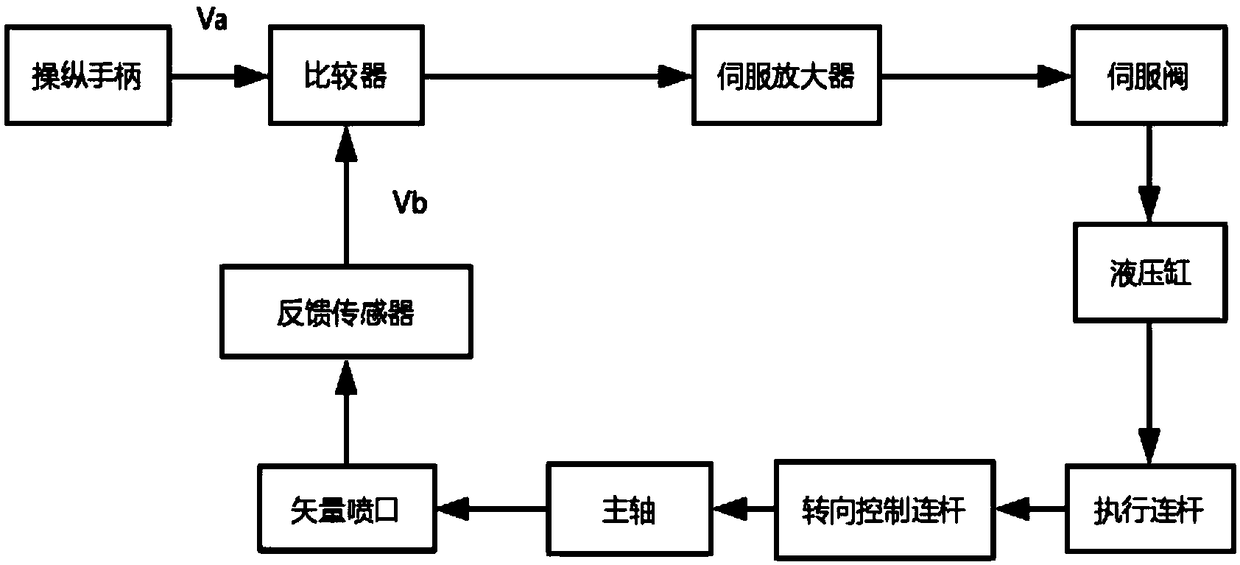

[0024] as attached figure 1 As shown, the present invention provides a spherical vector nozzle device of a double hydraulic symmetry system, which controls the rotation of the spherical vector nozzle 4 through a dual hydraulic drive assembly 7, and adjusts the change of the nozzle direction of the water jet, thereby controlling the water jet Change in thrust direction.

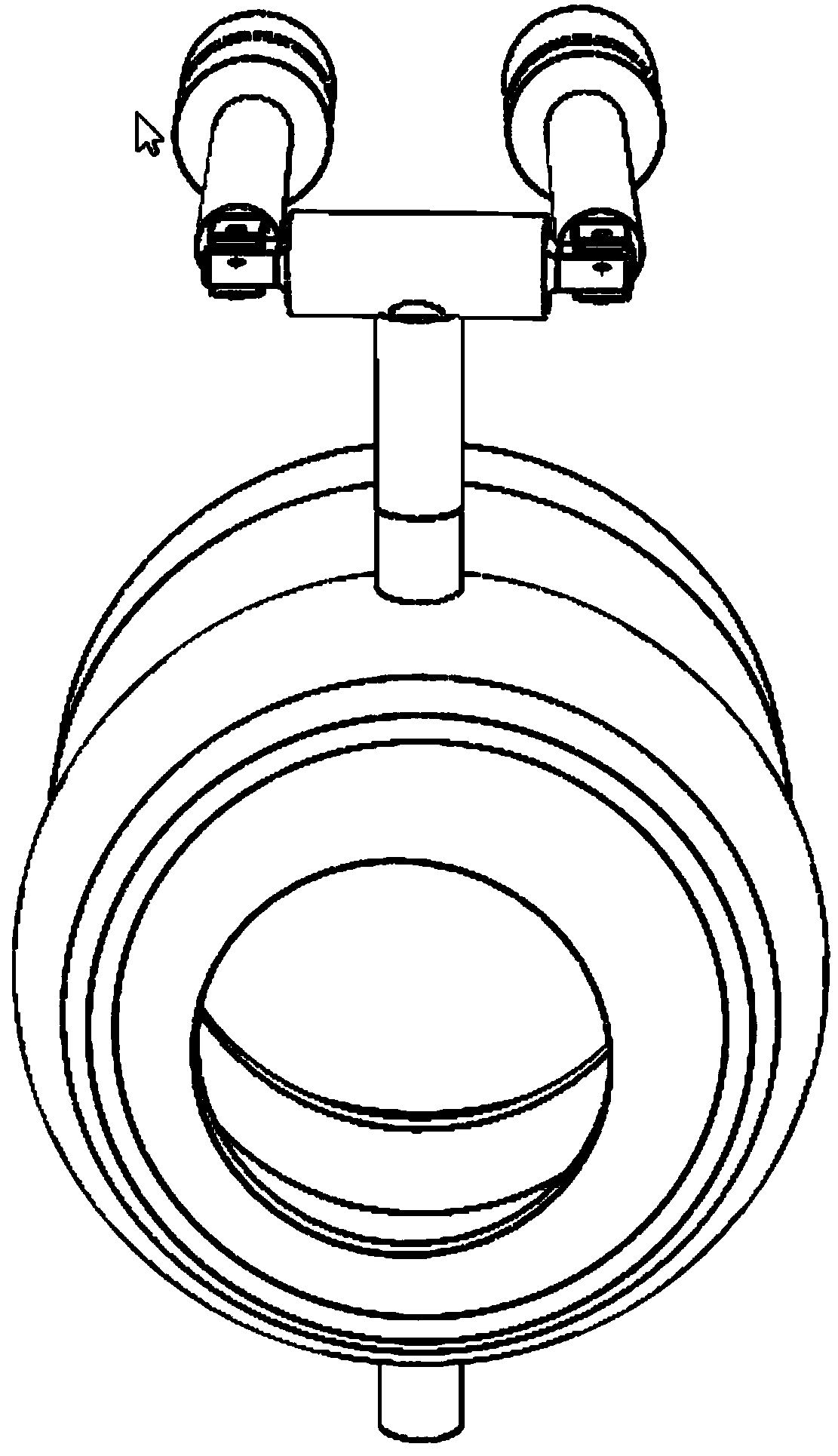

[0025] A spherical vector nozzle device with dual hydraulic symmetry system, such as figure 1 As shown, it includes: steering control connecting rod 1, main shaft 2, nozzle connection assembly 3, spherical vector nozzle 4, water jet propulsion pump flow channel 5, executive connecting rod 6, double hydraulic drive assembly 7, and auxiliary shaft 8.

[0026] as attached figure 1 As shown, the cross section of the spout connection assembly 3 is a U-like structure.

[0027] The spout conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com