Radiation crosslinked polyethylene foam and preparation method and application thereof

A polyethylene foam and radiation cross-linking technology, which is applied in the field of radiation cross-linked polyethylene foam and its preparation, can solve the problem that the expansion ratio of IXPE foam cannot exceed 45B, limit the application range of IXPE foam, and the appearance of foam Roughness and other problems, to achieve the effect of increasing the limit expansion ratio, reducing the temperature of granulation and extrusion, and reducing the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0076] As a preferred embodiment of the present invention, the melt index of the low-density polyethylene is 4.0-5.0g / 10min.

[0077] In a preferred embodiment of the present invention, by rationally adjusting the melt index of low-density polyethylene, the system has more suitable processing fluidity.

[0078] As a preferred embodiment of the present invention, the low density polyethylene has a melting point of 100-110°C. Using low-density polyethylene with low melting point and high melt index as the matrix can reduce the processing temperature for preparing radiation crosslinked polyethylene foam and further reduce the decomposition of blowing agent.

[0079] As a preferred embodiment of the present invention, the content of vinyl acetate in the ethylene-vinyl acetate copolymer is 5%-10%, and the typical but non-limiting vinyl acetate content in the ethylene-vinyl acetate copolymer is 5%, 6%, 7%, 7.5%, 8%, 9% or 10%; preferably, the melt index of the ethylene-vinyl acetat...

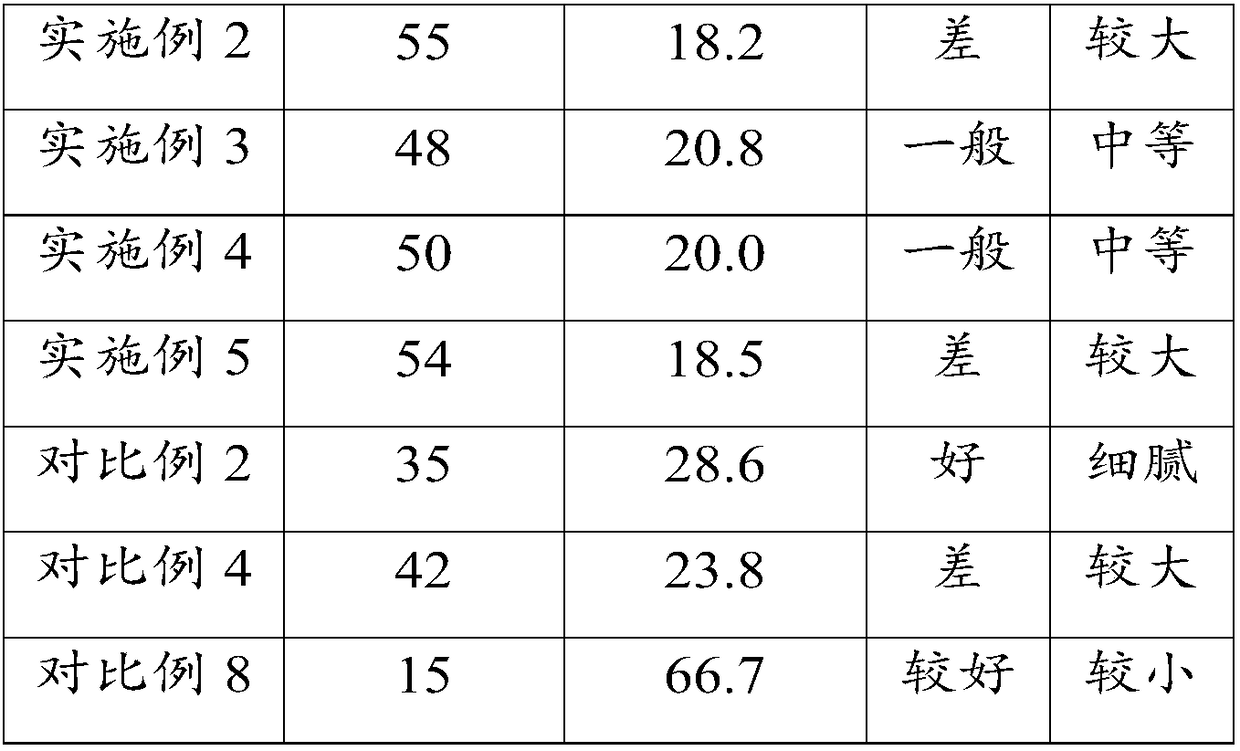

Embodiment 1

[0141] 1. Radiation cross-linked polyethylene foam

[0142] A radiation cross-linked polyethylene foam is mainly prepared from the following raw materials in parts by weight:

[0143] 68 parts of low-density polyethylene, 9 parts of ethylene-vinyl acetate copolymer, 20 parts of azodicarbonamide, 1 part of foaming aid, and 1.1 parts of antioxidant.

[0144] Among them, the grade of low-density polyethylene is Qatar 0474, the melting point is 105°C, and the melt index is 4.0g / 10min.

[0145] The trade mark of ethylene-vinyl acetate copolymer is EVA 14-2, and the content of vinyl acetate in the ethylene-vinyl acetate copolymer is 8%, and melt index is 2g / 10min.

[0146] The grade of azodicarbonamide is Korea Dongjin DF1500. The shape is spherical, the particle size is 13nm, and the decomposition temperature is 205-215°C.

[0147] The foaming aid is composed of ZnO and ZnSt; the weight ratio of ZnO and ZnSt is 2:1.

[0148] The antioxidant consists of DSTP and 1010; the weight...

Embodiment 2

[0163] 1. Radiation cross-linked polyethylene foam

[0164] A radiation cross-linked polyethylene foam is mainly prepared from the following raw materials in parts by weight:

[0165] 55 parts of low-density polyethylene, 3 parts of ethylene-vinyl acetate copolymer, 25 parts of azodicarbonamide, 0.3 parts of foaming aid, and 2 parts of antioxidant.

[0166] Wherein, each raw material is identical with embodiment 1.

[0167] 2. Preparation of radiation cross-linked polyethylene foam

[0168] Mix azodicarbonamide, antioxidant and LDPE according to the weight ratio of 25:2:35 to obtain the azodicarbonamide masterbatch containing antioxidant. Mix the foaming aid and LDPE according to the weight ratio of 0.3:5 to obtain the foaming aid masterbatch.

[0169] The preparation process of radiation cross-linked polyethylene foam is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com