A kind of PVA system melt special for optical film and its film preparation method

An optical film and melt technology, applied in optics, optical components, applications, etc., can solve the problems of insufficient surface smoothness of optical films, polycrystalline points of optical films, color spots, affecting the optical performance of films, etc., to reduce color spots. Produces, smoothes the surface, facilitates dissolution and modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

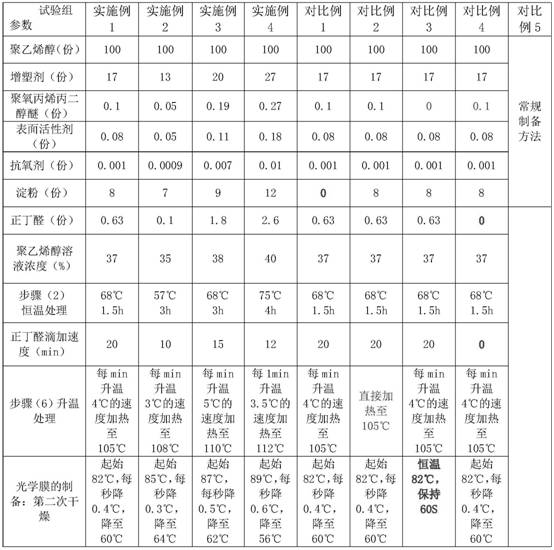

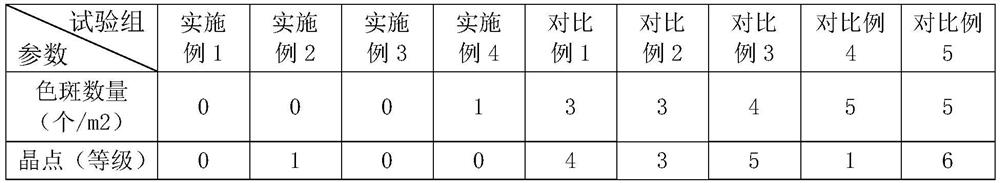

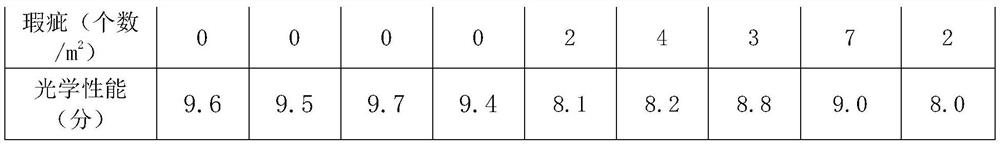

Examples

Embodiment 1

[0041] This embodiment discloses a PVA-based melt with good fluidity. The PVA-based melt includes polyvinyl alcohol-based polymers, water, starch, n-butyraldehyde, plasticizers, surfactants and antioxidants. The PVA-based melts The melt has a melt flow index of 28 g / min at a temperature of 106° C., a load of 2.24 kg, and a water content of 40-80%. After several researches by the applicant, it was found that the optical film prepared from the PVA-based melt has a smooth surface, fewer crystal points, and excellent optical properties; The probability of film breakage during the process is very small; and when dyeing, the dye can be evenly distributed on the optical film to ensure the uniformity of film dyeing.

[0042] The flow index of the PVA-based melt is tested on a melt flow rate meter according to the test method of GB3682-2000.

[0043] A special PVA-based melt for optical films. The preparation steps of the PVA-based melt are completed under the protection of an inert g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com