Method and device for preparing high-purity indium oxide powder by electrolysis

A technology of indium oxide and electrolysis, which is applied in the direction of electrolysis components, electrolysis process, electrodes, etc., can solve the problems of easy agglomeration of indium oxide powder, uneven particle size distribution, poor batch consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

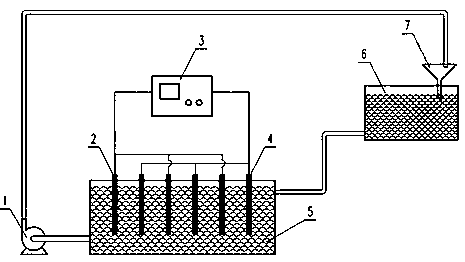

Method used

Image

Examples

Embodiment 1

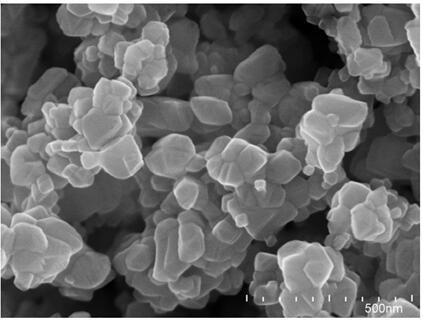

[0025] Embodiment 1: the method for preparing high-purity indium oxide powder by this electrolytic method is to be equipped with the NH of concentration 2mol / L 4 NO 3 The solution (pH is 6, temperature is 20°C) is carried out in an electrolytic cell, and three high-purity indium plates (purity 99.992) are set in the electrolytic cell as positive electrodes and three high-purity indium plates are used as negative electrodes, and positive electrodes and negative electrodes alternate Set up, the anode and cathode electrodes are connected to the positive and negative poles of the power supply respectively, and electrolysis is performed after turning on the power supply, the power supply voltage is 10V, and the current density is 10mA / cm 2 ; During the electrolysis process, the polarity of the positive electrode and the negative electrode is exchanged, the exchange time interval is 30s, and the precipitation in the electrolytic cell is collected at an interval of 5h, and washed 3 t...

Embodiment 2

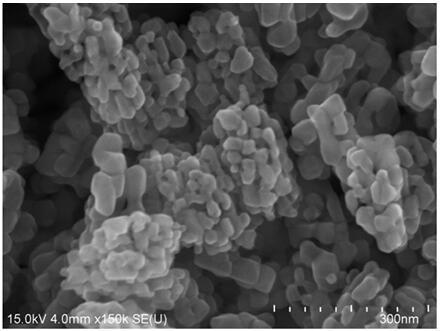

[0030] Embodiment 2: the method for preparing high-purity indium oxide powder by this electrolytic method is to be equipped with the NH of concentration 5mol / L 4 Cl solution (pH 10, temperature 25°C) electrolytic cell, 5 high-purity indium plates (purity 99.993) are set in the electrolytic cell as anode electrodes and 5 high-purity indium plates as cathode electrodes, anode electrodes and cathode electrodes Alternately set, the anode and cathode electrodes are connected to the positive and negative poles of the power supply respectively, and electrolysis is performed after turning on the power supply, the power supply voltage is 5V, and the current density is 50mA / cm 2 ; During the electrolysis process, the polarity of the positive electrode and the negative electrode is exchanged, the exchange time interval is 10s, and the precipitation in the electrolytic cell is collected at an interval of 2h, and washed 4 times with ultrapure water and absolute ethanol in sequence (until th...

Embodiment 3

[0034] Embodiment 3: the method for preparing high-purity indium oxide powder by this electrolytic method is to be equipped with the NH of concentration 1mol / L 4 One high-purity indium plate (purity 99.995) is set in the electrolytic cell of Cl solution (pH is 8, temperature is 55°C) as the positive electrode and one high-purity indium plate is the negative electrode, the positive electrode and the negative electrode are arranged alternately, and the positive electrode The positive and negative electrodes of the power supply and the negative electrode are connected to the positive and negative poles of the power supply, and the electrolysis is performed after turning on the power supply. The power supply voltage is 1V and the current density is 80mA / cm 2 ; During the electrolysis process, the polarity of the positive electrode and the negative electrode is exchanged, the exchange time interval is 50s, and the precipitation in the electrolytic cell is collected at an interval of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com