Cable trough main bearing T-beam composite material sidewalk and installation method thereof

A technology of composite materials and cable troughs, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as construction difficulties, low construction efficiency, and inconvenience, and achieve the effects of low strength requirements, long life, and material cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

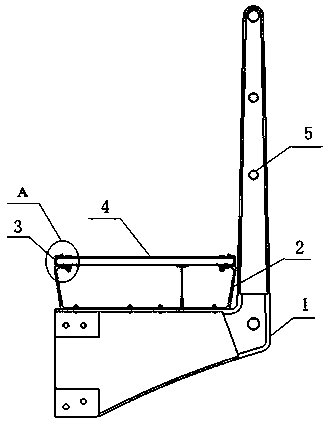

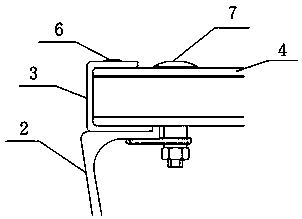

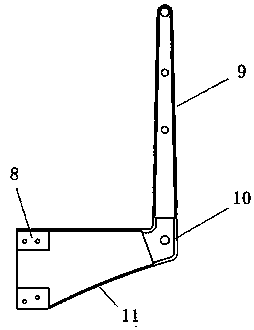

[0030] Please refer to Figure 1 to Figure 7 A cable trough main bearing T-beam composite sidewalk includes a bracket 1, a cable trough 2, a walking board edge beam 3, a walking board 4, and a guardrail round pipe 5. The support 1, the cable trough 2, the side beams 3 of the walking board, the walking board 4, the guardrail round pipe 5, etc. are all made of composite materials. The bracket includes a T-beam connection block 8, a column 9, a corner connector 10, and a beam 11. The lower end of the column is connected to the right end of the beam through a corner connector; The connection block is provided with a through hole through which the bolt can pass, and is used for connecting the pre-embedded metal parts on the T beam through the bolt. The uprights are provided with round holes for the round pipes of the guardrail to pass through. Generally, about three holes are arranged evenly. The cable duct includes a bottom plate 12, a left side plate 13, a right side plate 14, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com